Device for spray lubricating wind turbine transmission

A wind turbine and transmission technology, which is applied in the directions of engine lubrication, transmission parts, turbines, etc., can solve problems such as increasing the risk of transmission failure, and achieve simple cost and good wetting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

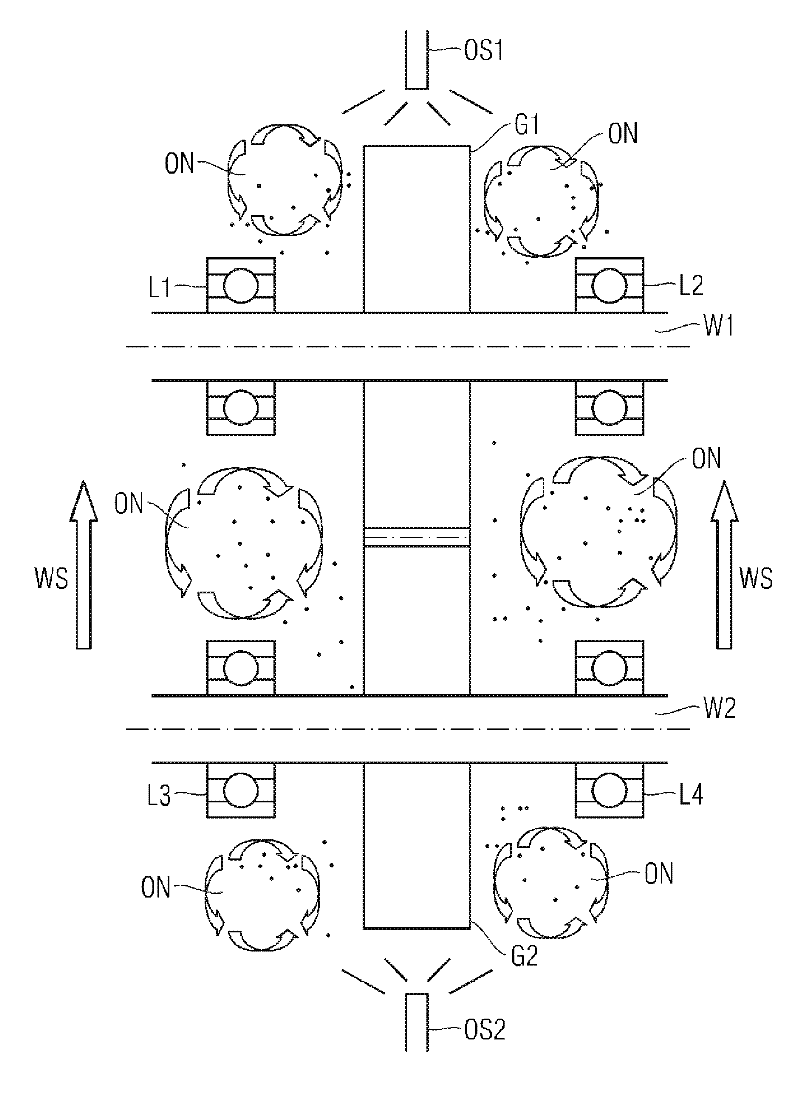

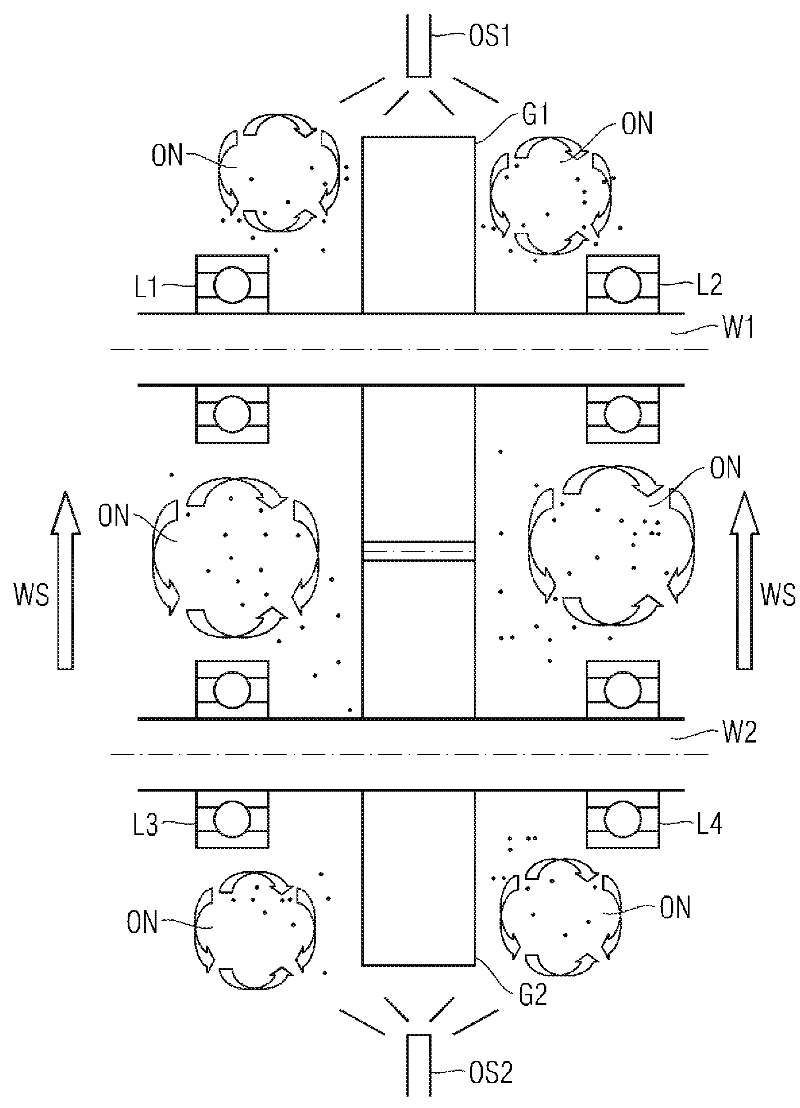

[0015] The device according to the invention comprises a transmission, which in figure 1 is represented schematically by two spur gears G1 , G2 , two transmission shafts W1 , W2 and four bearings L1 , L2 , L3 , L4 . The gears G1 , G2 , W1 , W2 , L1 , L2 , L3 , L4 are surrounded by a gear housing (not shown).

[0016] The device according to the invention also includes two fuel injection devices OS1 , OS2 which together form a fuel injection system. The oil spray devices OS1 , OS2 are arranged spatially separated from one another on the transmission housing and nonetheless at least their spray heads are located inside the housing. In a preferred embodiment, the oil injection devices OS1 , OS2 are mounted on the inner side of the transmission housing.

[0017] except two in figure 1 In addition to the fuel injection devices OS1 and OS2 shown in the middle part, other fuel injection devices may also belong to the fuel injection system.

[0018] The two oil injection devices O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com