Cooling and heat radiation structure of capacitor

A heat dissipation structure and capacitor technology, applied in capacitors, electrical components, etc., can solve problems such as temperature rise and damage to the capacitor shell, and achieve a good effect of cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

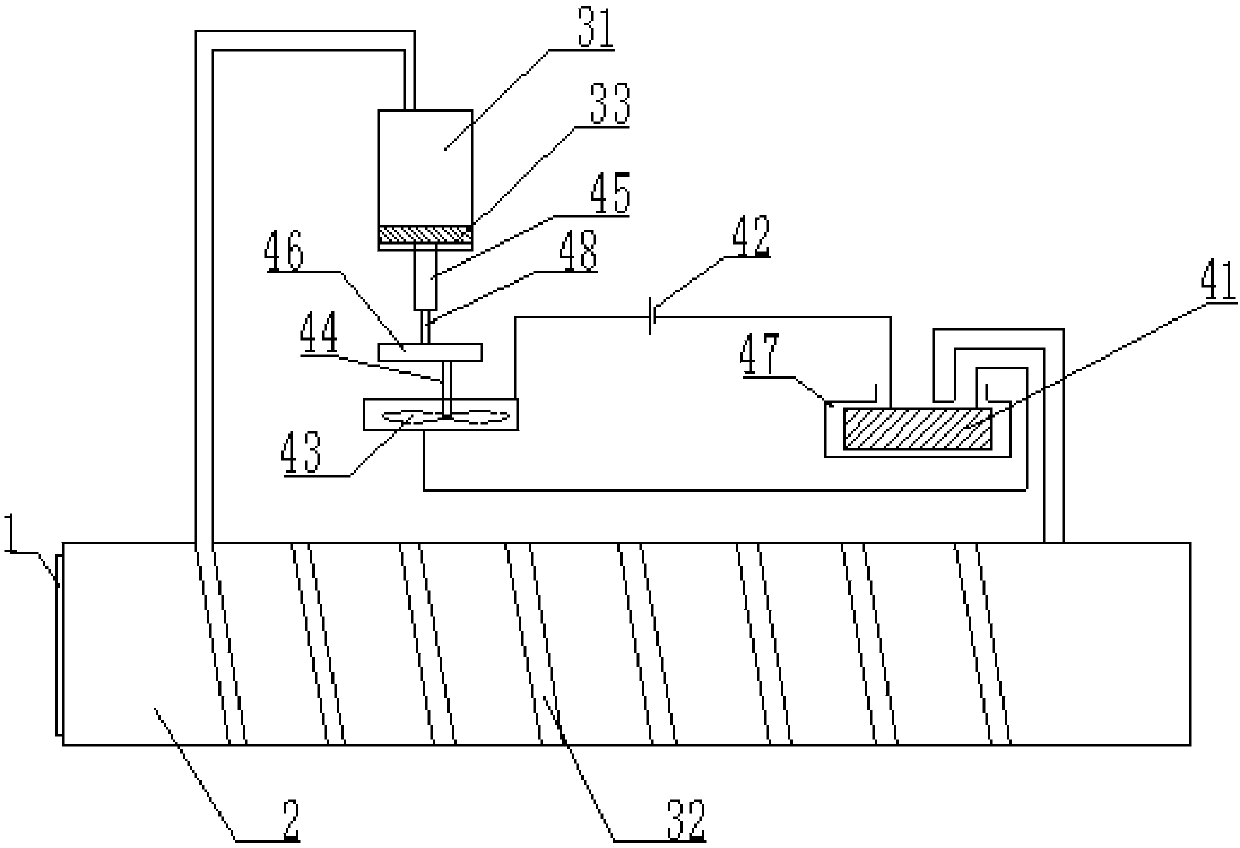

[0017] The reference signs in the drawings of the description include: capacitor 1, insulating paper 2, water tank 31, water pipe 32, piston 33, cardboard 41, power supply 42, fan 43, rotating shaft 44, bushing 45, deceleration gear set 46, cardboard slot 47, threaded rod 48.

[0018] Such as figure 1 Shown is a cooling and heat dissipation structure for a capacitor, including a cooling mechanism, a heat dissipation mechanism, and a plurality of capacitor elements connected in parallel. The capacitor element is wrapped with a layer of insulating paper 2 .

[0019] Wherein, the cooling mechanism includes a water tank 31 and a water pipe 32, the water pipe 32 is connected to the water tank 31, and the water pipe 32 is spirally wound on the capacitor 1 wrapped by the insulating paper 2, so that the capacitor 1 part can receive a uniform cooling effect, and at the same time A part of the gap is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com