Apparatus for the melt spinning and cooling of filament family

A filament bundle and spinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of flow resistance and uneven cold air delivery, and achieve the effect of improving performance and avoiding rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

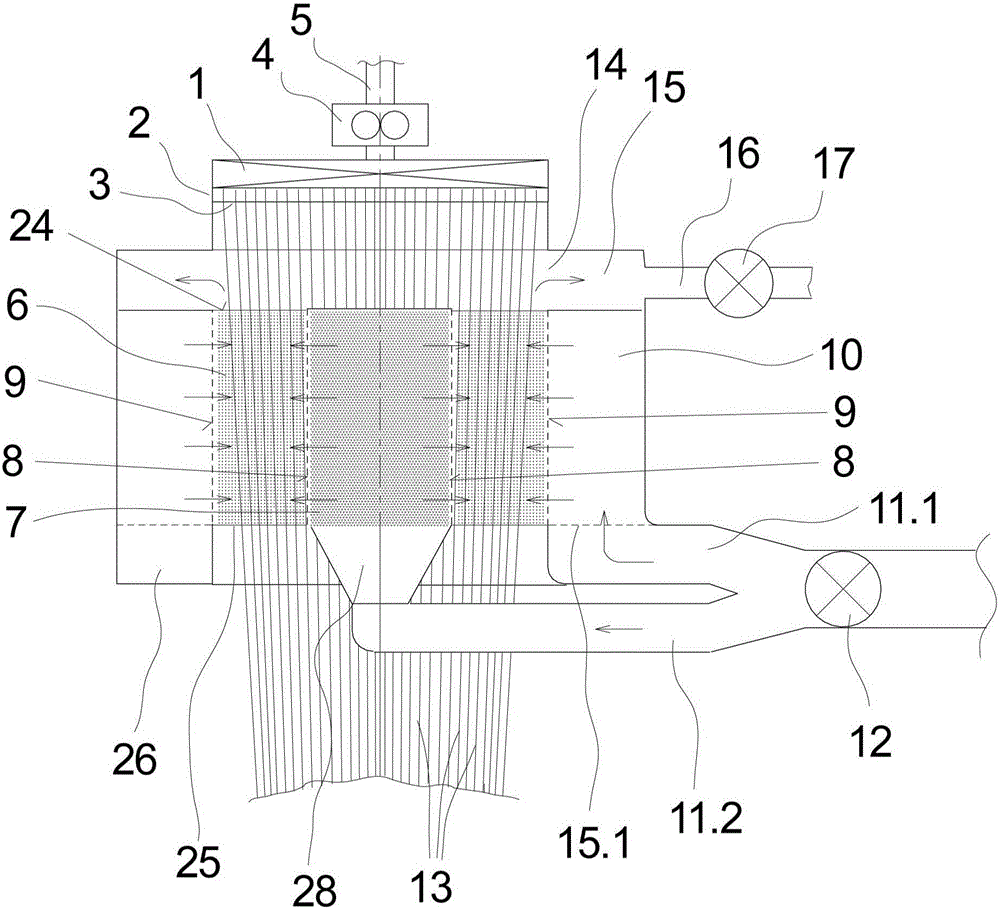

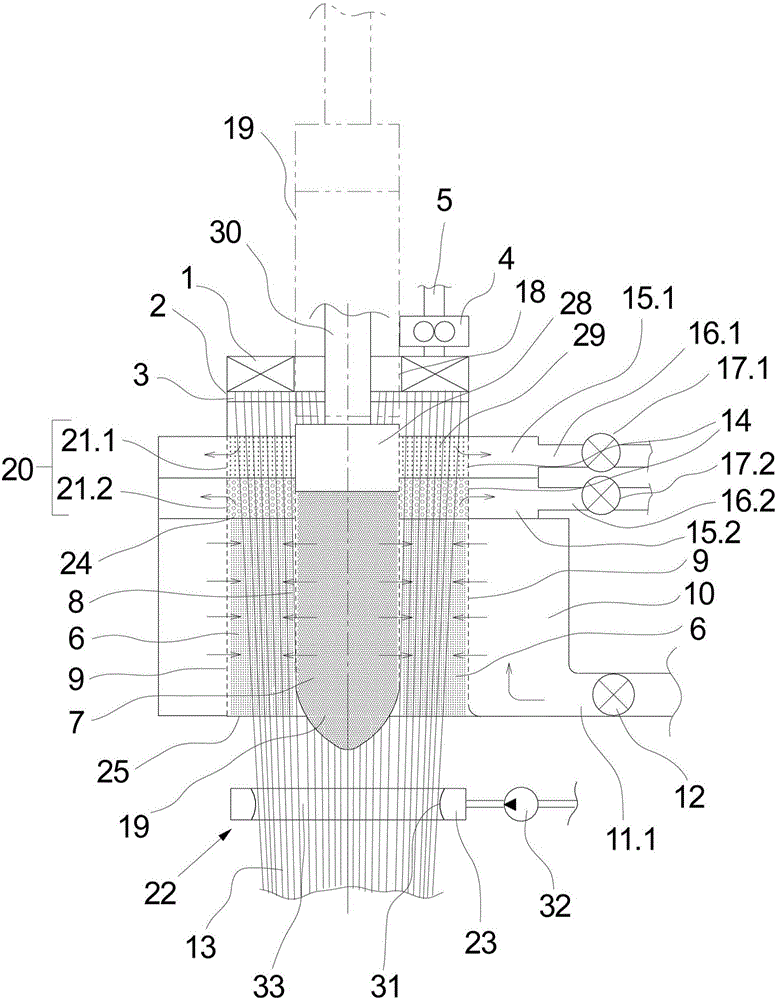

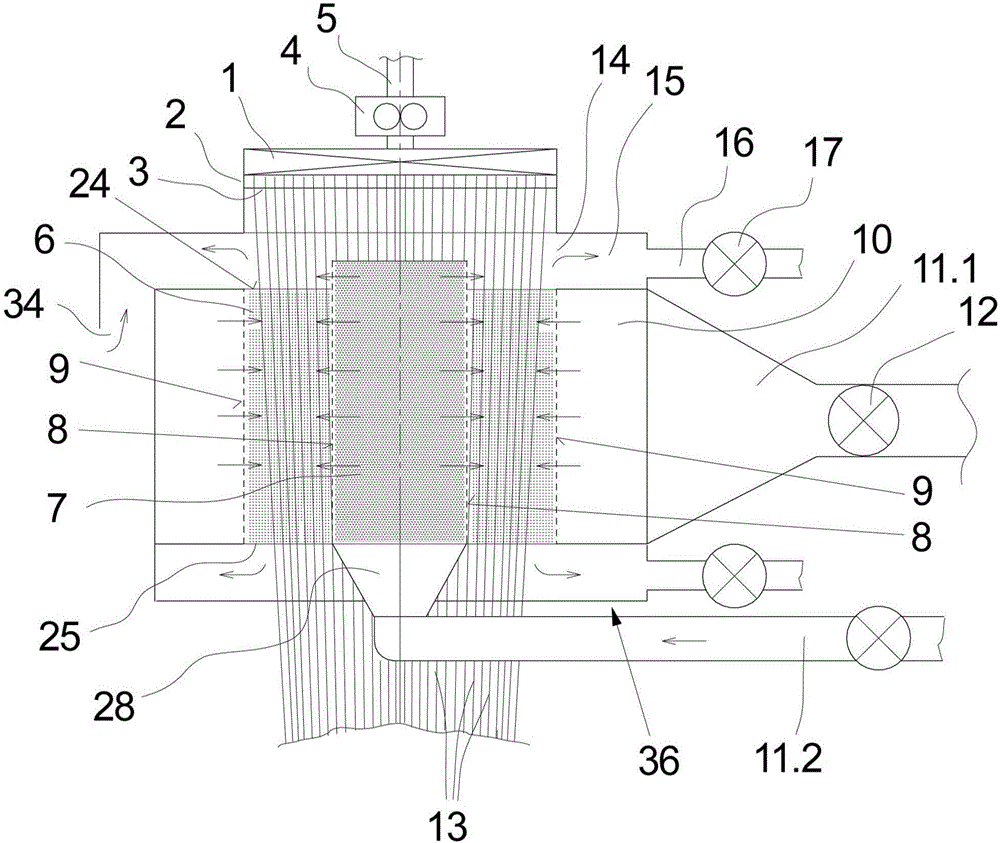

[0027] exist figure 1 A first embodiment of the device for melt-spinning and cooling filament bundles according to the invention is schematically shown in longitudinal section. In this case, only the inventive components essential to the invention are shown schematically.

[0028] This embodiment has a spinning nozzle 1 which on its underside comprises a nozzle plate 2 having a plurality of spinning holes 3 arranged in a ring. The spinning nozzle 1 is connected to a spinning pump 4 which is connected via a melt supply 5 to a melt source (not shown here).

[0029] The spinning nozzle 1 and the spinning pump 4 are usually installed in a heated spinning box. Here, the spinning nozzle 1 is held on the spin beam floor.

[0030] Below the spinning nozzle 1 , an annular cooling tunnel 6 is formed coaxially to the spinning nozzle 1 in such a way that the filament strands extruded through the spinneret openings 3 of the nozzle plate 2 can pass through the cooling tunnel 6 without co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com