89 DEG C phase change material (PCM)

A technology of phase change energy storage materials and corrosion inhibitors, which is applied in heat exchange materials, chemical instruments and methods, heat exchanger types, etc., can solve problems such as strong corrosion, poor thermal conductivity, and easy leakage, and achieve inhibition Effect of condensation, improvement of conductivity, and improvement of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

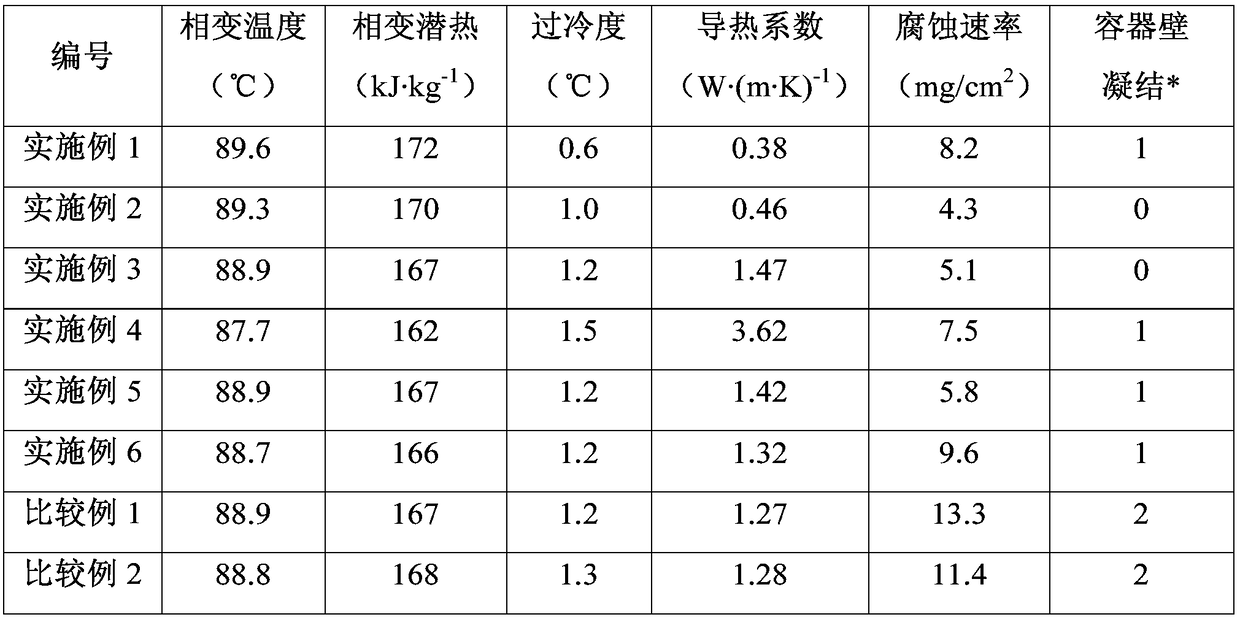

Examples

Embodiment 1

[0041] Weigh 100 parts by weight of magnesium nitrate hexahydrate, put it into a stainless steel airtight container after pulverization, place it in a KDM type temperature-controlled electric heating mantle and heat it to 92°C, then add 0.1 part by weight of hexadecylamine while stirring, to Completely melt into a melt, add 0.1 parts by weight of sodium dodecylbenzenesulfonate to the melt, and ultrasonically disperse for 30 minutes to obtain a dispersion; add 0.5 parts by weight of graphite and 1 part by weight of carboxylate to the dispersion Sodium methylcellulose and 0.5 parts by weight of carmine are fully mixed and stirred evenly, and then cooled to obtain a phase change energy storage material.

Embodiment 2

[0043]Weigh 100 parts by weight of magnesium nitrate hexahydrate, put it into a stainless steel airtight container after crushing, place it in a KDM type temperature-controlled electric heating mantle and heat it to 93°C, then add 0.5 parts by weight of hexadecylamine while stirring, to Completely melt into a melt, add 0.5 parts by weight of sodium dodecylbenzenesulfonate to the melt, and ultrasonically disperse for 35 minutes to obtain a dispersion; add 1 part by weight of graphite and 2 parts by weight of carboxylate to the dispersion Sodium methylcellulose and 0.5 parts by weight of tartrazine are thoroughly mixed and stirred evenly, and then cooled to obtain a phase change energy storage material.

Embodiment 3

[0045] Weigh 100 parts by weight of magnesium nitrate hexahydrate, put it into a stainless steel airtight container after crushing, place it in a KDM temperature-controlled electric heating mantle and heat it to 93°C, then add 1 part by weight of hexadecylamine while stirring, to Completely melt into a molten liquid, add 1 weight part of sodium dodecylbenzenesulfonate to the molten liquid, and ultrasonically disperse for 35 minutes to obtain a dispersion liquid; add 2.5 weight parts of graphite and 5 weight parts of carboxylate to the dispersion liquid Sodium methylcellulose and 0.5 parts by weight of tartrazine are thoroughly mixed and stirred evenly, and then cooled to obtain a phase change energy storage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com