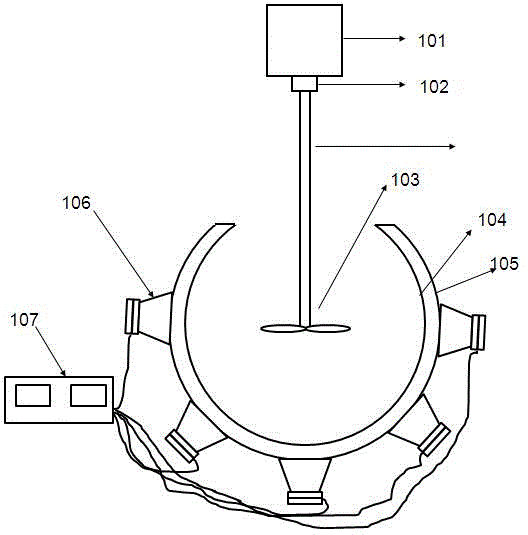

Ultrasonic stirring apparatus for lithium ion battery electrode slurry

A lithium-ion battery and stirring device technology, applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of difficult wetting, easy adhesion of solid materials on the wall of the barrel, insufficient uniformity of manual intervention, etc., to achieve easy uniformity Quality, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The feedstock is first pretreated to dehydrate it. The pretreatment methods are respectively, lithium manganate and PVDF are baked at 120 degrees Celsius for 2 hours, SP and SO are baked at 200 degrees Celsius for 2 hours, and the solvent NMP is dehydrated with dry molecular sieves. Weigh 30 kg of lithium manganate, 900 g of SP, 390 g of SO, 970 g of PVDF, and 19 kg of NMP. First add NMP and PVDF to the barrel, start figure 1 In the mixer shown, the rotation speed of the dispersing paddle is set at 800 rpm, and the mixer is stirred for 60 minutes to obtain a uniform glue solution. Then, lithium manganese oxide, SP, and SO were divided into 3 parts, and one part was added every 30 minutes, and the rotation speed of the dispersion slurry was set at 800 rpm. After all the powder is completely wetted by the glue, set the speed of the dispersion slurry to 2900 rpm for high-speed stirring, and continue high-speed stirring for 240 minutes. Turn on the ultrasonic transducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com