Environment-friendly construction site dust suppressant and preparing method thereof

A technology for construction sites and dust suppressants, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult mass production, long production cycle, high product price, etc., and achieve enhanced moisturizing performance and natural compatibility. Good, less damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

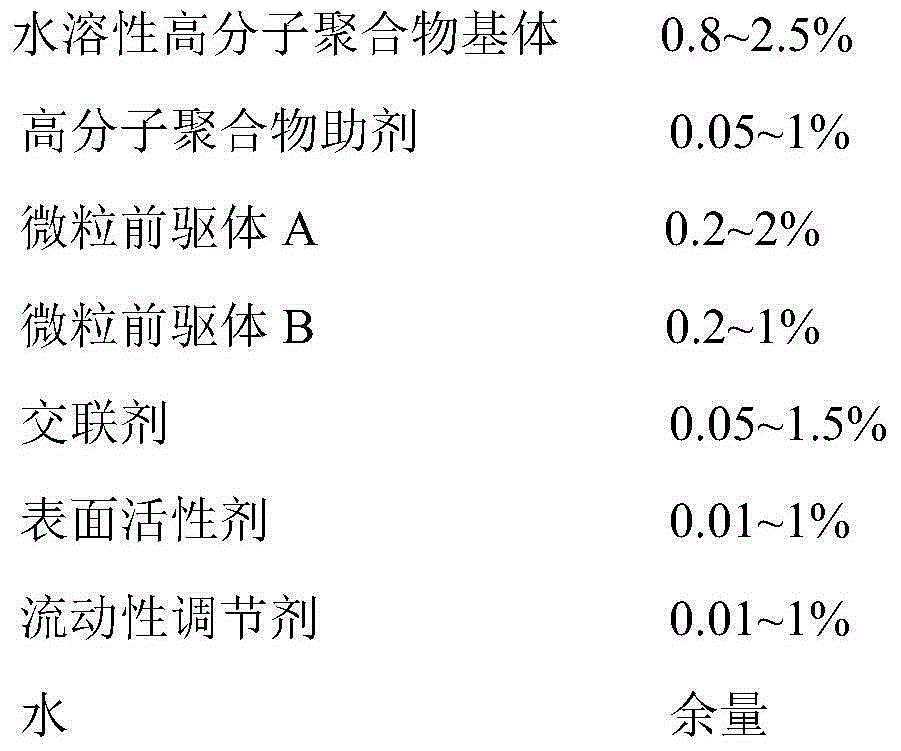

Method used

Image

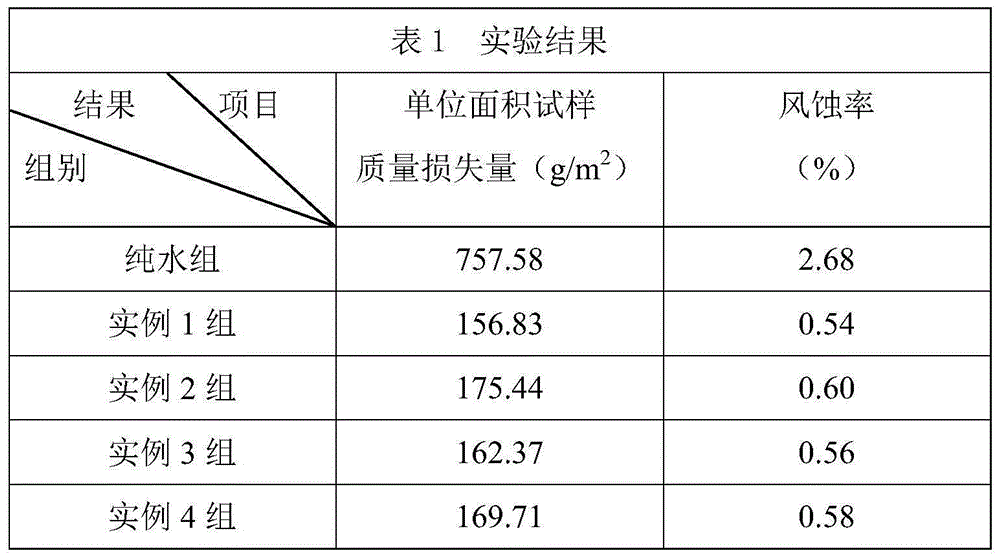

Examples

Embodiment 1

[0028] Add 0.8g of polyanionic cellulose and 0.4g of hydroxypropyl methylcellulose into 85g of water, and stir evenly to obtain a matrix solution; dissolve 0.2g of calcium chloride and 0.25g of potassium carbonate in 12.59g of water, and add the calcium chloride solution to Stir the matrix solution evenly, then add the potassium carbonate solution into the matrix solution and stir evenly; continue to stir for 3 hours, during which time add 0.05g xylitol, 0.01g fatty acid sulfoalkyl ester, and 0.7g urea in turn to obtain an environmentally friendly construction site dust suppressant finished product.

Embodiment 2

[0030] Add 1.6g of sodium carboxymethylcellulose and 0.3g of hydroxypropylmethylcellulose into 80g of water, and stir evenly to obtain a matrix solution; dissolve 1.2g of sodium silicate and 0.89g of oxalic acid in 15.11g of water, and dissolve the sodium silicate solution Add the matrix solution and stir evenly, then add oxalic acid into the matrix solution and stir evenly; continue stirring for 4 hours, during which time add 0.4g glycerol, 0.3g sodium dodecylbenzenesulfonate, and 0.2g urea in sequence to obtain an environmentally friendly construction site Finished dust suppressant.

Embodiment 3

[0032] Add 2.5g of hydroxyethylcellulose and 0.05g of hydroxypropylmethylcellulose into 80g of water, and stir evenly to obtain a matrix solution; dissolve 0.31g of calcium nitrate and 0.2g of sodium carbonate in 14.04g of water, and add the calcium nitrate solution to the matrix Stir the solution evenly, then add sodium carbonate to the matrix solution and stir evenly; continue to stir for 5 hours, during which time, add 0.9g propylene glycol, 1g succinate sulfonate, and 1g urea in sequence to obtain the finished environmental-friendly dust suppressant for construction sites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com