Micro optical sensor for laser dust particle counter

A particle counter and optical sensor technology, applied in scientific instruments, individual particle analysis, particle and sedimentation analysis, etc., can solve the problems of difficult miniaturization of the whole machine, poor uniformity of illumination intensity in the light-sensitive area, and different signal spectrum width, etc., to achieve Eliminate external electromagnetic interference, improve lighting uniformity, and improve collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

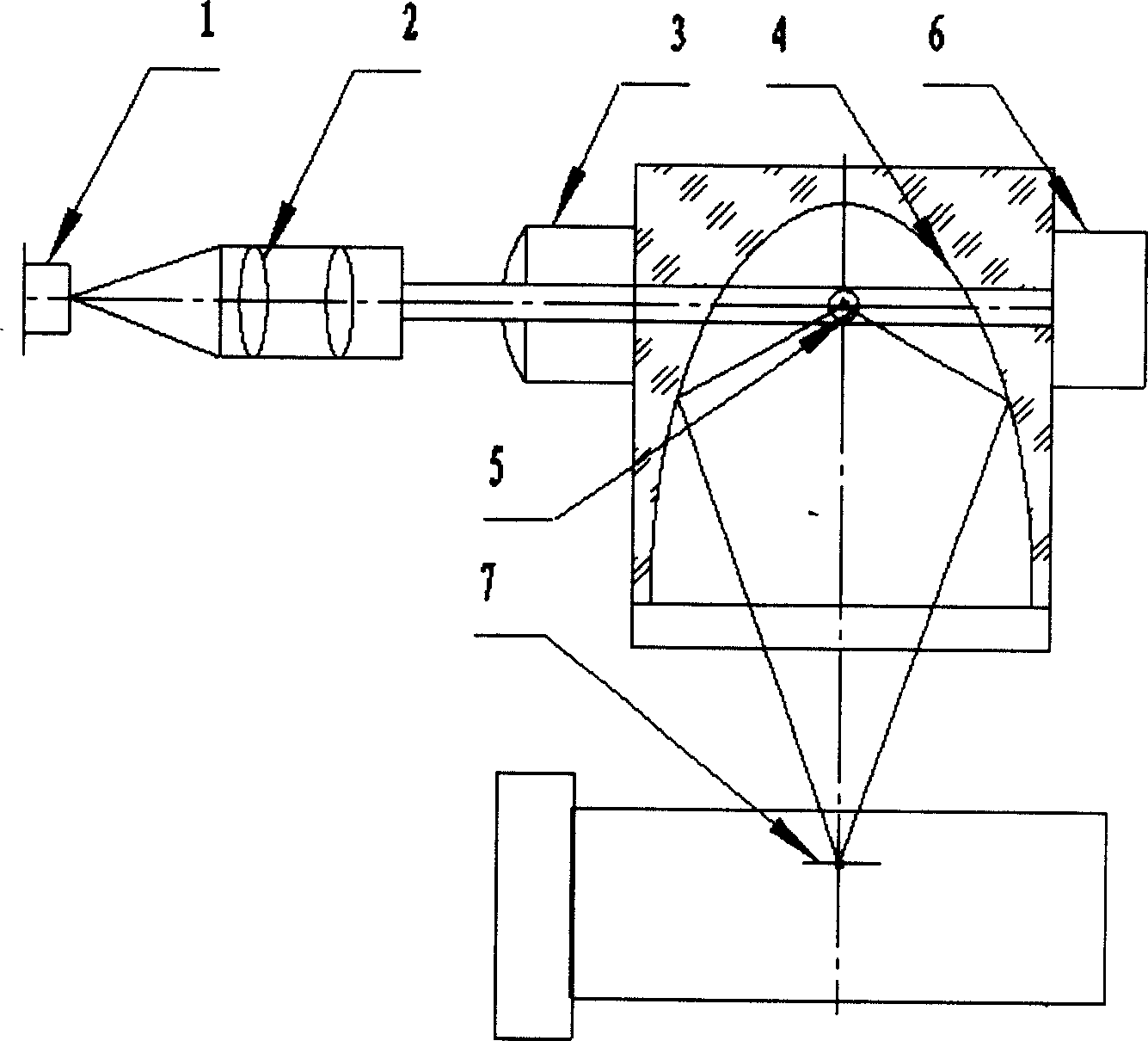

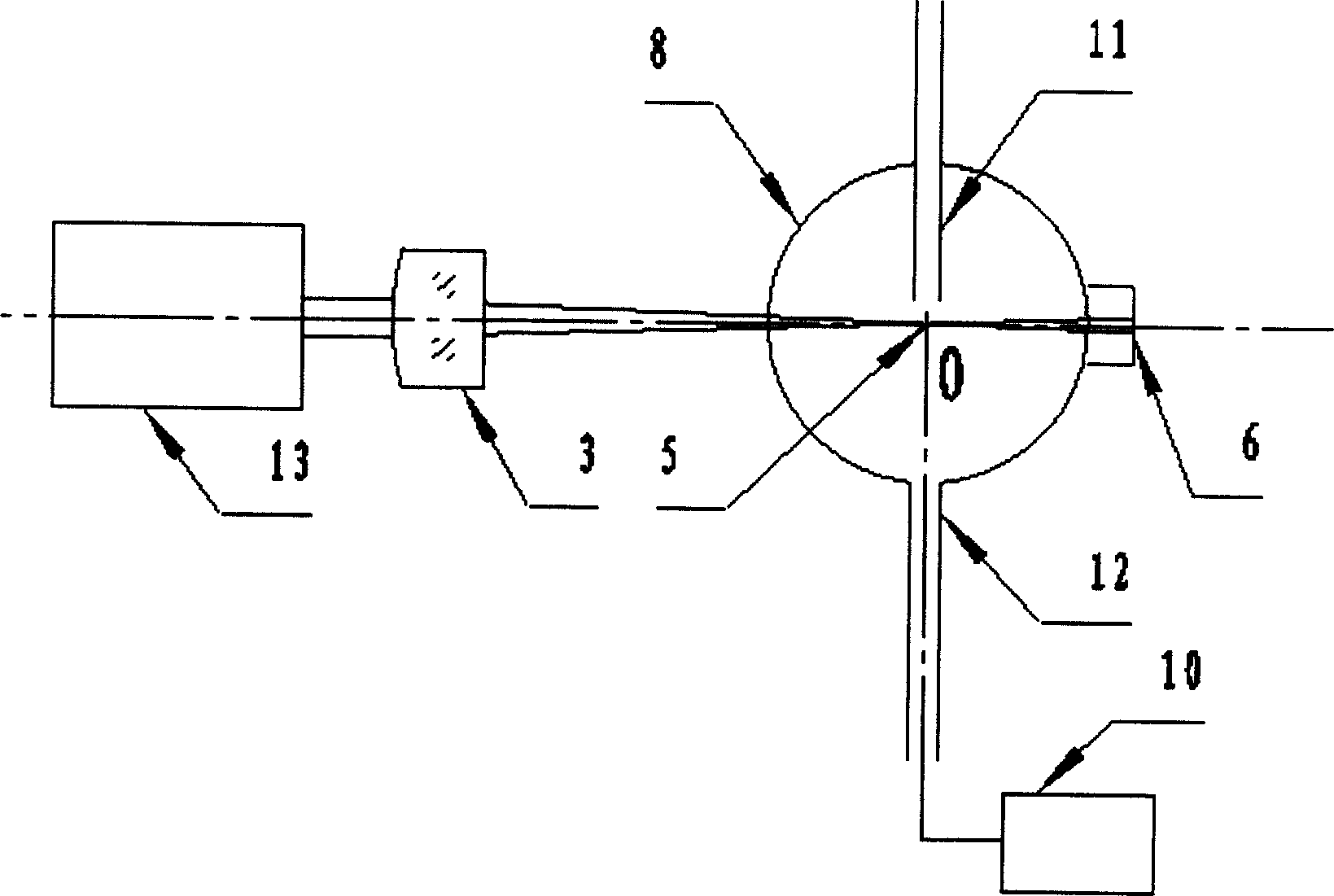

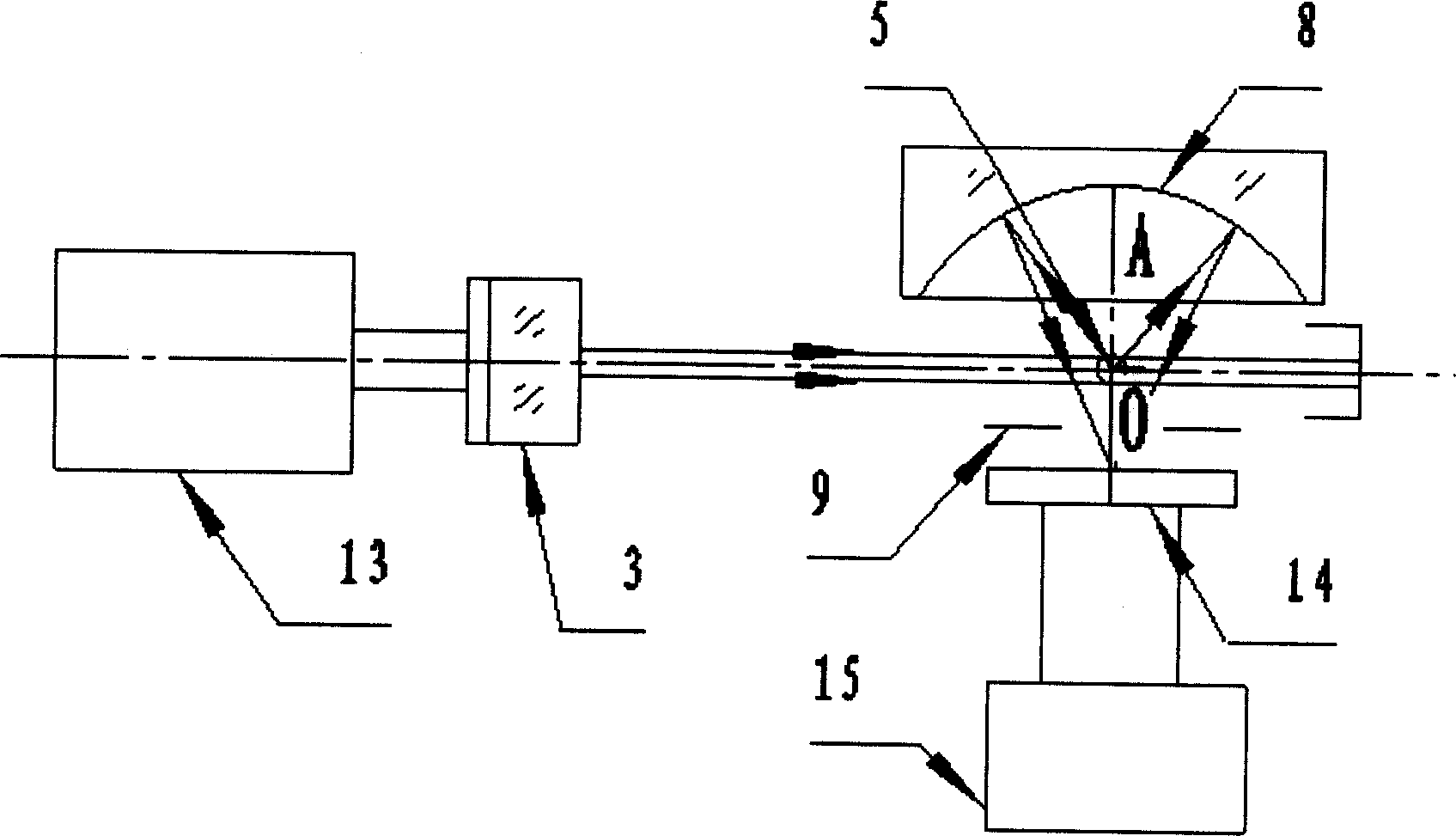

[0037] see figure 2 and image 3 . figure 2 and image 3 It is a structural schematic diagram of the laser dust particle counter miniature optical sensor of the present invention, by figure 2 and image 3 It can be seen that the micro optical sensor of the laser dust particle counter of the present invention is a right-angle scattering optical system, including an illumination system, a scattered light collection system, an air system and a preamplification circuit. The illumination system consists of a laser light source assembly 13 , a cylindrical mirror 3 and an optical trap 6 . The laser light source assembly 13 emits a collimated laser beam, which is one-dimensionally focused on the photosensitive area 5 by the cylindrical mirror 3, and the focal line is located in the plane formed by the optical axis of the illumination system and the optical axis of the scattered light collection system, and is perpendicular to the airflow direction . The laser beam enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com