Weak surface rock slope grouting method and anchor tube for grouting

A rocky slope and grouting technology, which is applied in the field of grouting devices and rocky slope reinforcement, can solve the problems of insufficient filling of cracks and easy grouting, and achieve improved stability, low cost, and enhanced resistance. The effect of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

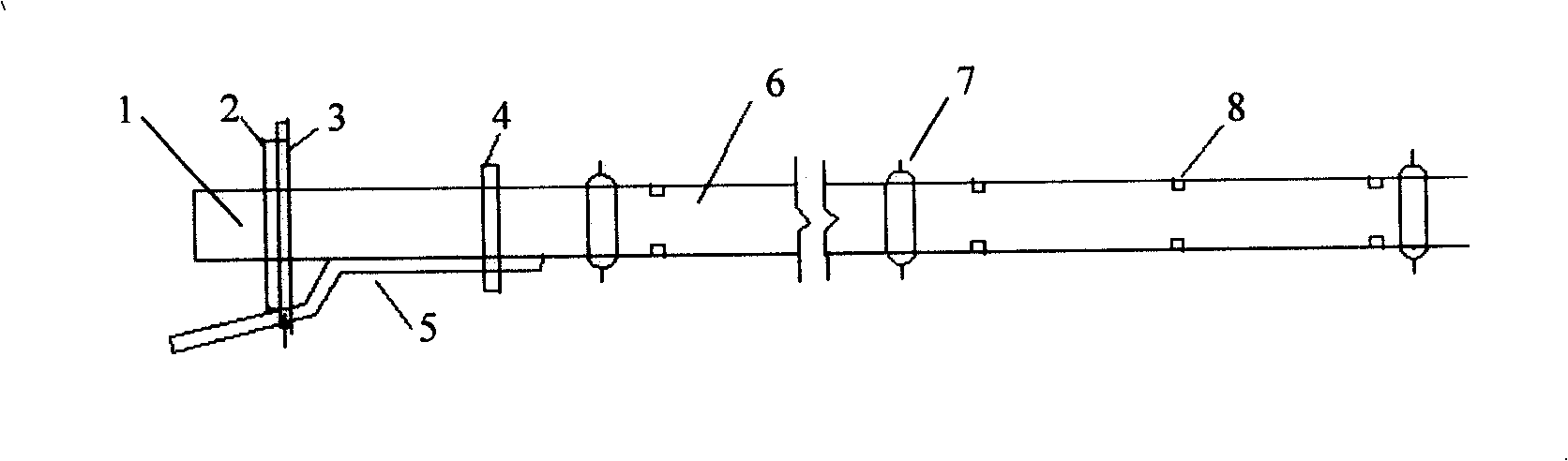

[0016] use The anchor pipe body (6) is made of ordinary straight seam welded pipe, the first row of grouting holes (8) is drilled from the hole bottom 20cm, the centering bracket (7) is welded at the bottom of the hole, and the grouting holes are drilled every 20 (8 ), and the centering bracket (7) is welded respectively on the upper section and the middle section of the anchor pipe body (6). Set a backing plate and nut (2) on the anchor head (1) as a prestressing device, set a stopper (4) at a distance of 800mm from the backing plate (3), and the lower part of the stopper is connected to the inlet of the grout return pipe (5). The grout return pipe outlet extends out of the anchor hole.

Embodiment 2

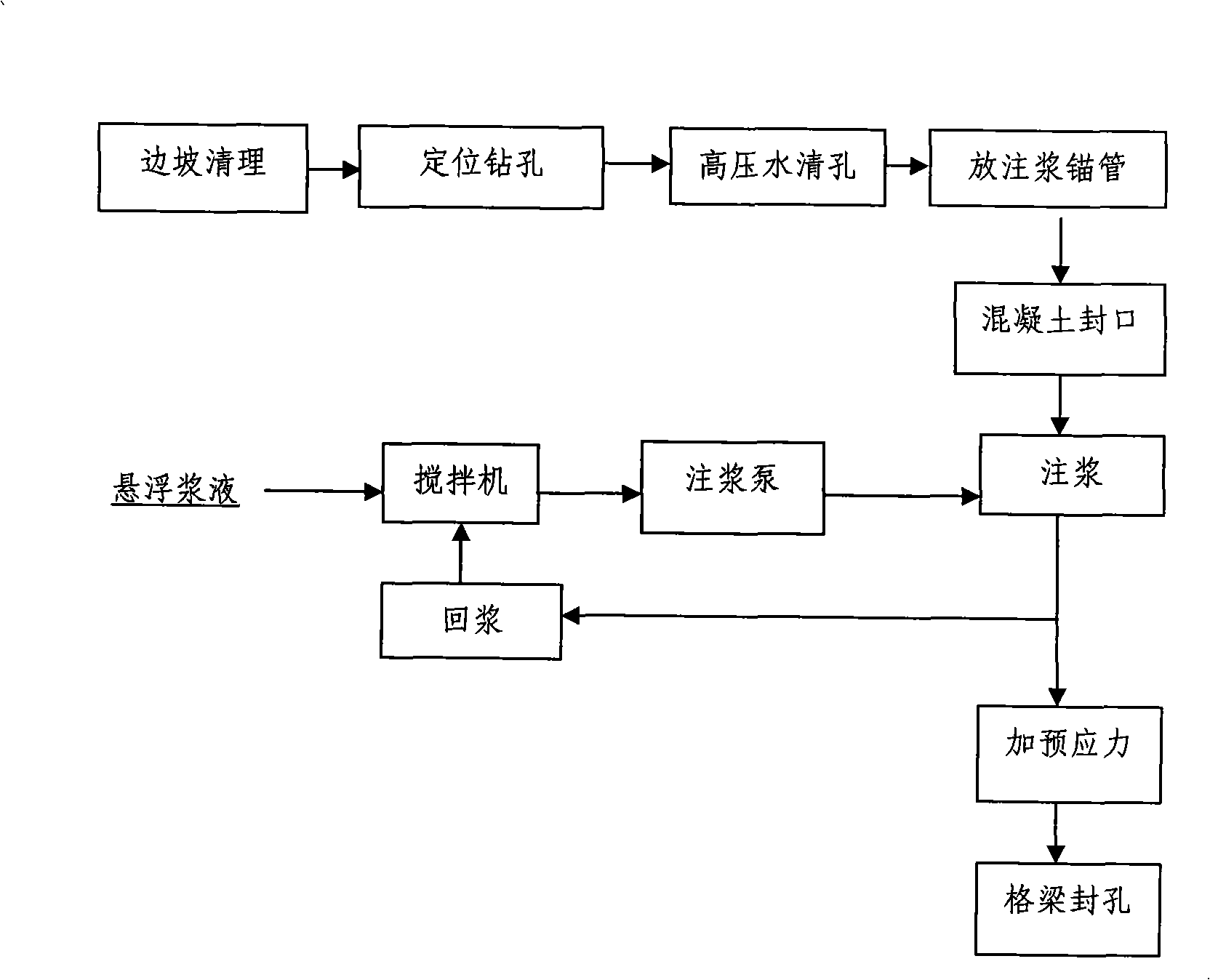

[0018] The left slope of an expressway section is a broken limestone slope with clay interlayer. The slope is 240m long and the maximum height is 39.6m, which is a forward slope. The slope is divided into four levels, each level of slope is 10m high, and the slope ratio is 1:0.75~1:1. The slope is cut by four groups of joints and several faults, and the groundwater of the natural slope at the top of the slope penetrates into the faults and fissures, causing the interlayer clay to soften and lose, and shallow rock strata to slip along the bed. The owner of the expressway requires ecological protection on the slope, no shotcrete, and shallow reinforcement of the slope. use image 3 The process flow shown implements cyclic grouting.

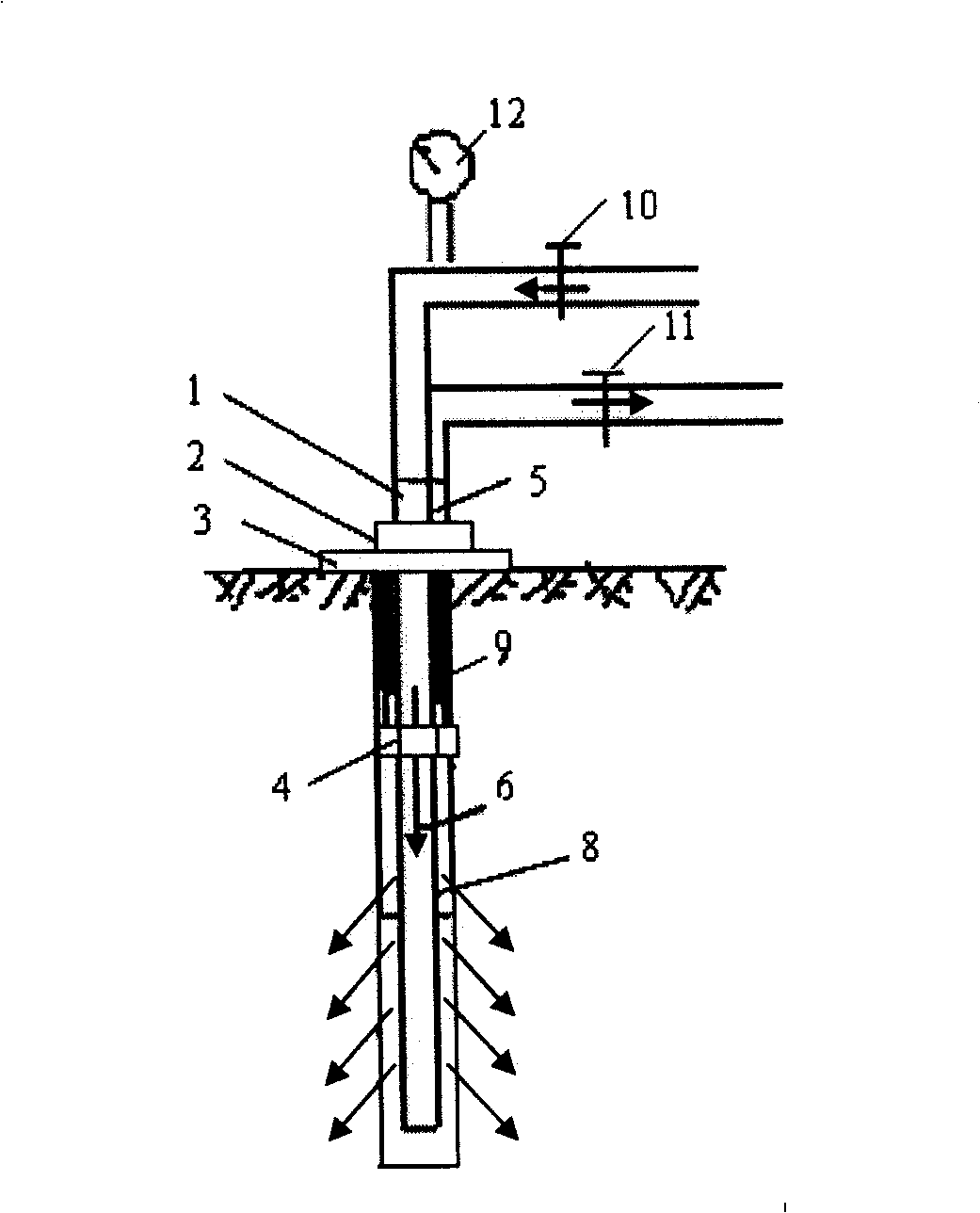

[0019] Such as figure 2 As shown, after cleaning the side slope, the anchor hole with a diameter of 54 mm and a depth of 4 to 6 m is drilled, and the anchor hole diameter is 100 mm larger than the outer diameter of the anchor pipe body (6). Cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com