Air cathode-based miniature direct formic acid fuel cell

A formic acid fuel cell, air cathode technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc. Formic acid corrosion performance is durable, overcomes the effect of being easily corroded by formic acid, and reduces the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

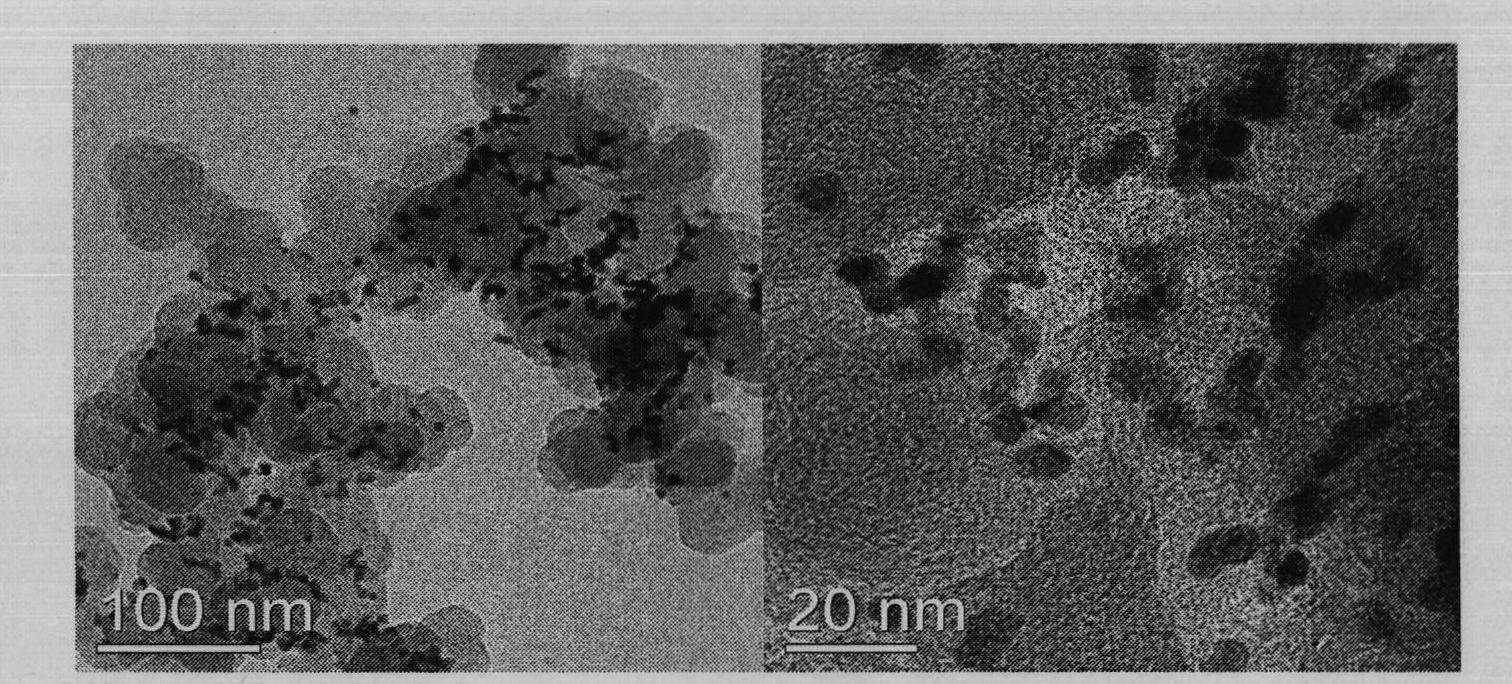

[0054] Catalyst preparation method, comprises the steps:

[0055] (1) Weigh 83.4 mg metal precursor PdCl 2 , add 0.2ml concentrated hydrochloric acid (mass concentration 36%), join in the flask that fills 15ml ethylene glycol after ultrasonic dissolution, the power of ultrasonic wave is 150W, and frequency is 40KHz, obtains component A;

[0056] (2) 200mg XC-72R (conductive carbon black produced by U.S. Cabot Company, code-named: Vulcan XC-72R) joins in the 50ml flask of filling 10ml ethylene glycol, ultrasonic dispersion obtains component B; The power of ultrasonic wave is 150W, The frequency is 40KHz.

[0057] (3) Weigh 1035 mg of sodium citrate and add it to a 50 ml beaker containing 15 ml of ethylene glycol to obtain component C according to the molar ratio of sodium citrate to metal precursor being 7.5:1;

[0058] (4) Add component C dropwise to component B to obtain component D;

[0059] (5) Add component A dropwise to component D to obtain component E.

[0060] (6) ...

Embodiment 2

[0062] Similar to the preparation of Pd / C in Example 1, there are the following differences: the metal precursor H used in component A 2 PtCl 6 ·6H 2 O130mg, the prepared catalyst is marked as Pt / C.

Embodiment 3

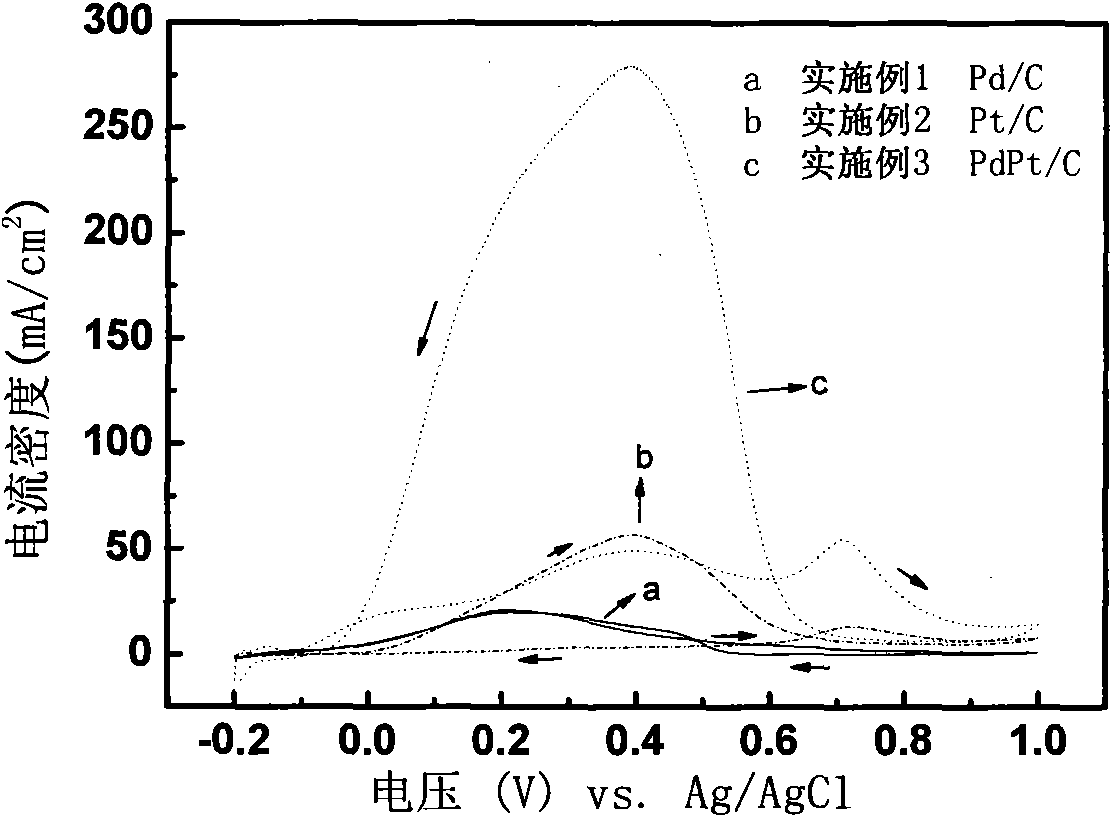

[0064] Similar to the preparation of Pd / C in Example 1, there are the following differences: the metal precursor H used in component A 2 PtCl 6 ·6H 2 O 80mg, PdCl 2 30mg, the prepared catalyst is marked as PdPt / C. image 3 Show the catalytic performance of different catalysts to formic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com