Organic waste treatment device for spatial permanent base

A technology for organic waste and treatment equipment, which is applied in the field of organic waste treatment equipment in permanent space bases, and can solve problems such as insufficient contact between materials and oxygen, insufficient stability of oxygen consumption rate test, inability to perform both aerobic and anaerobic fermentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

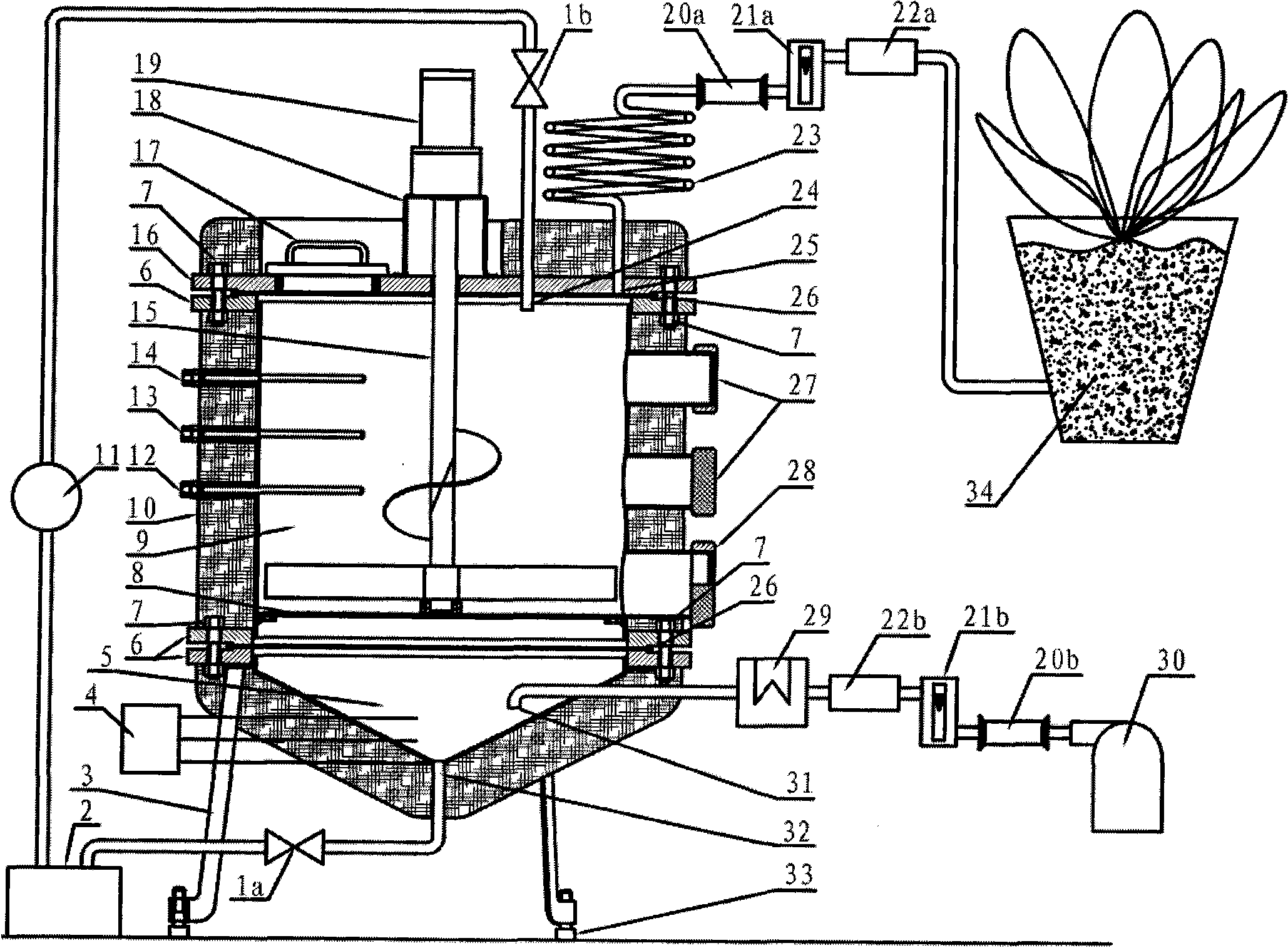

[0020] During aerobic fermentation, figure 1 30 in it is an air pump or a gas cylinder with a certain oxygen concentration gas. In the bio-regenerative life support system, oxygen is a very precious bio-protection substance. Some compartments or equipment output gas with low oxygen content or high concentration of CO 2 Such as gas, can not be used to breathe. However, aerobic fermentation has much lower gas requirements than humans, as long as the partial pressure of oxygen can meet the requirements of aerobic fermentation. Therefore, during aerobic fermentation, air that is not suitable for breathing can be used as input gas to maintain the aerobic fermentation process at a lower operating cost.

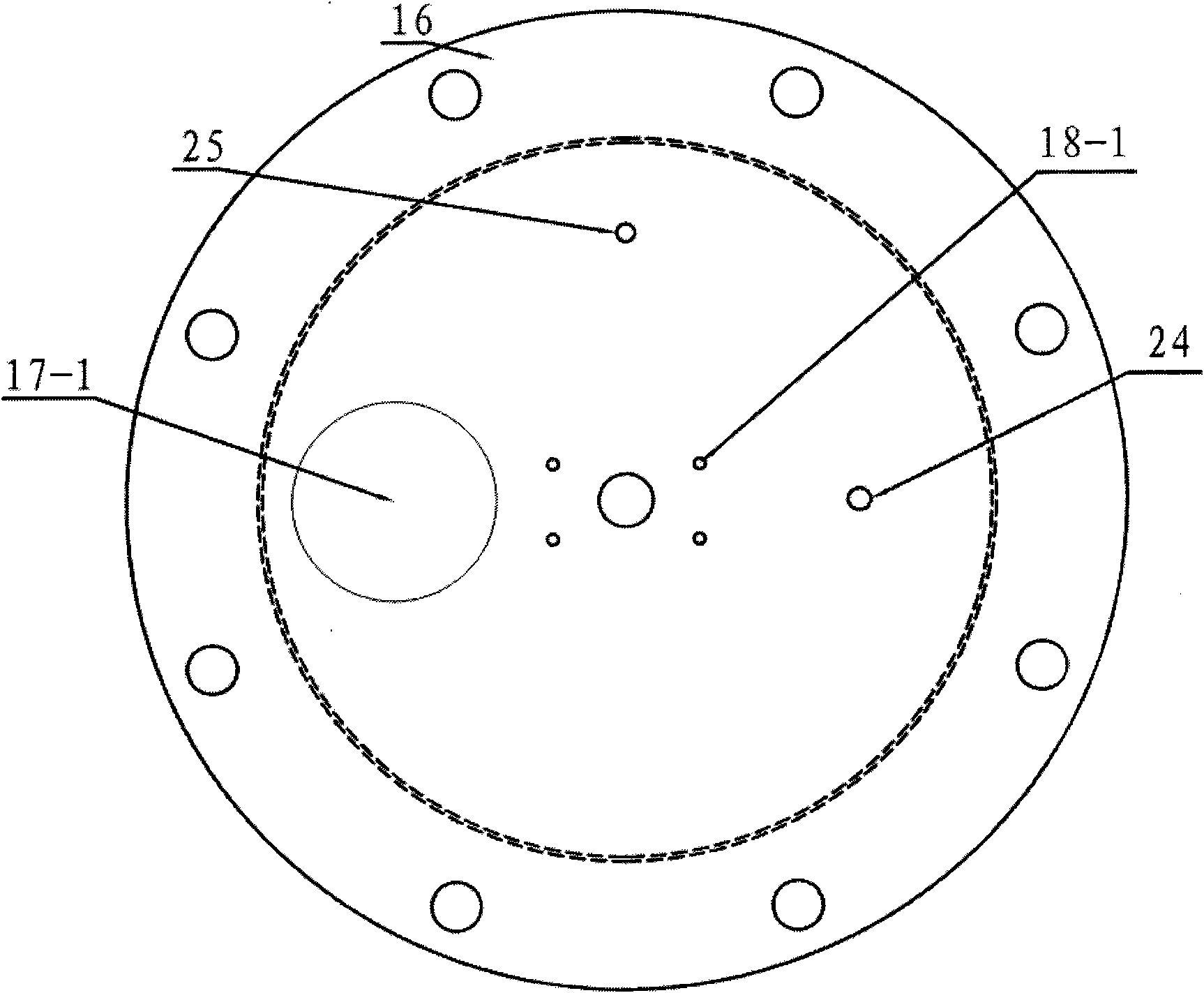

[0021] Before fermentation, the solid waste should first be crushed to a certain particle size, mixed with the partially decomposed fermentation material, and the moisture content should be adjusted to about 60%, and the pH value should be neutral. Then its feed port 17 ( figur...

Embodiment 2

[0026] During anaerobic fermentation, figure 1 30 in it is a nitrogen cylinder or a gas cylinder containing gas with an extremely low oxygen concentration. Before fermentation, continuous aeration is required to discharge the oxygen in the device. During the fermentation process, continuous aeration or intermittent aeration can be selected to prevent CH 4 If the concentration of anaerobic fermentation products is too high, it will affect the reaction process. The motor 19 rotating speed is about 1rpm, and its purpose is only to prevent material agglomeration. The sensor module 22 only needs to measure CO 2 Concentration and CH 4 concentration. The rest of the operations are similar to aerobic fermentation. The material after combined aerobic and anaerobic treatment is suitable for use as a plant cultivation substrate in nature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com