Efficient crushing device for construction waste

A crushing device and construction waste technology, applied in the direction of dust removal, liquid separation agent, cleaning method and utensils, etc., can solve the problem of large land acquisition fees, construction funds for garbage removal and transportation, and insufficient recycling of iron materials , Waste of reusable resources and other issues, to achieve sustainable development, avoid wanton diffusion, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

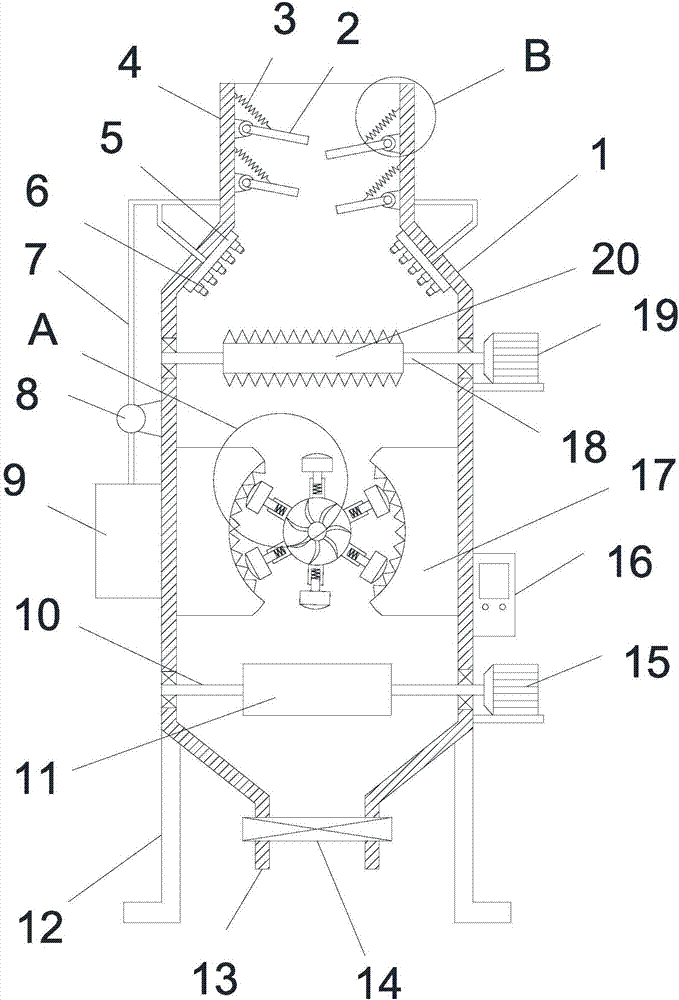

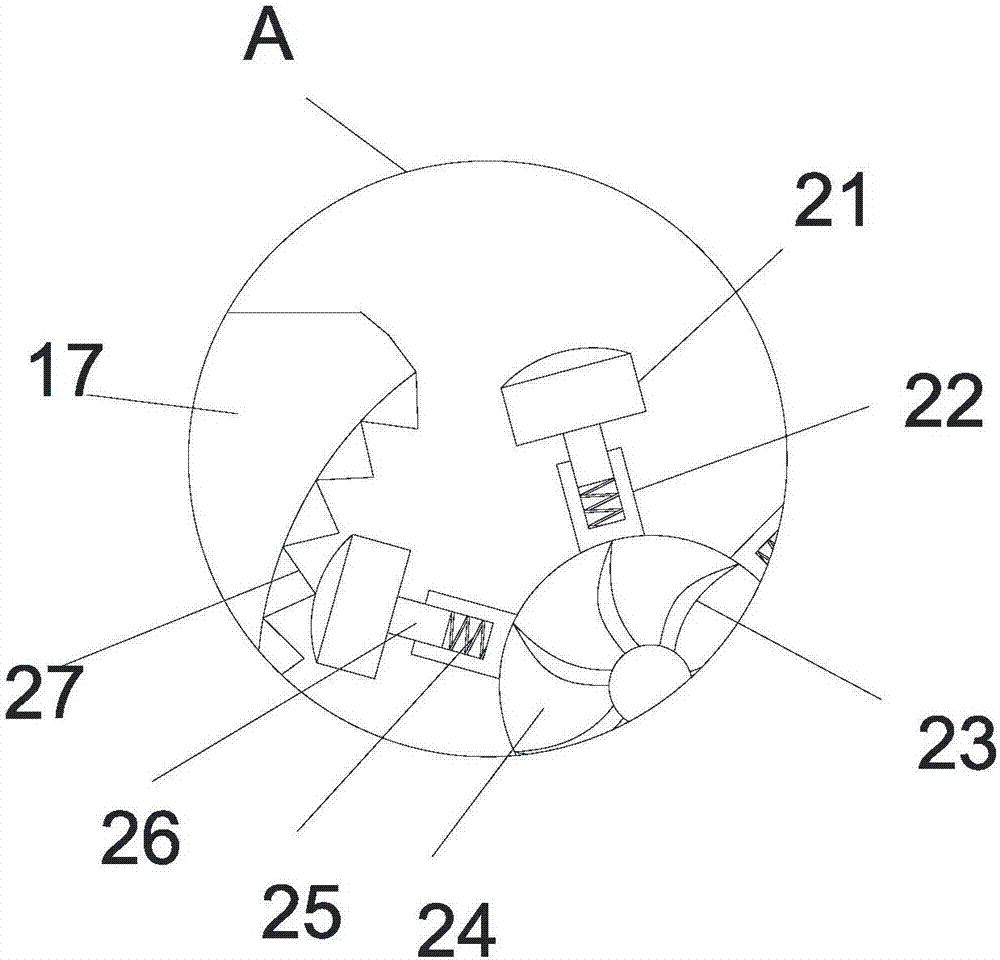

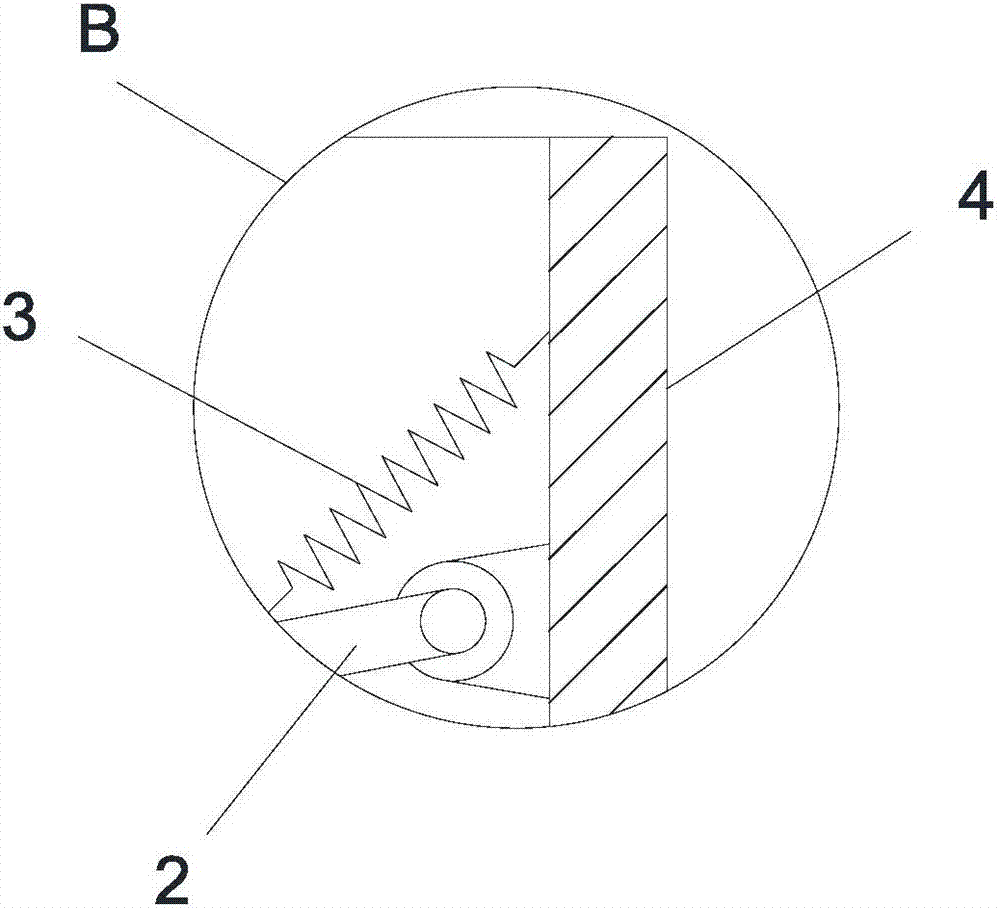

[0019] see Figure 1-3 , a high-efficiency crushing device for construction waste, including a crushing box 1, a feeding pipe 4 is arranged on the top of the crushing box 1, and a plurality of buffer plates 2 are arranged alternately on the inner wall of the feeding pipe 4, and one end of the buffer plate 2 is hinged On the inner wall of the feed pipe 4, the limit spring 3 is connected between the inner wall of the feed pipe 4 and the side of the buffer plate 2; A spray nozzle 6, a water tank 9 is arranged on the outer wall of the left side of the crushing box 1, and a catheter 7 is connected between the water tank 9 and the water collection tray 5, and a water pump 8 is installed on the catheter 7; the right side of the crushing box 1 A second motor 19 is arranged on the outer wall, and a second rotating shaft 18 is arranged horizontally in the crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com