Road dust depressor and preparation method thereof

A dust suppressant and road technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of toxicity, volatile secondary pollution, and single function, achieve safe use, simple daily operation, and improve the working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

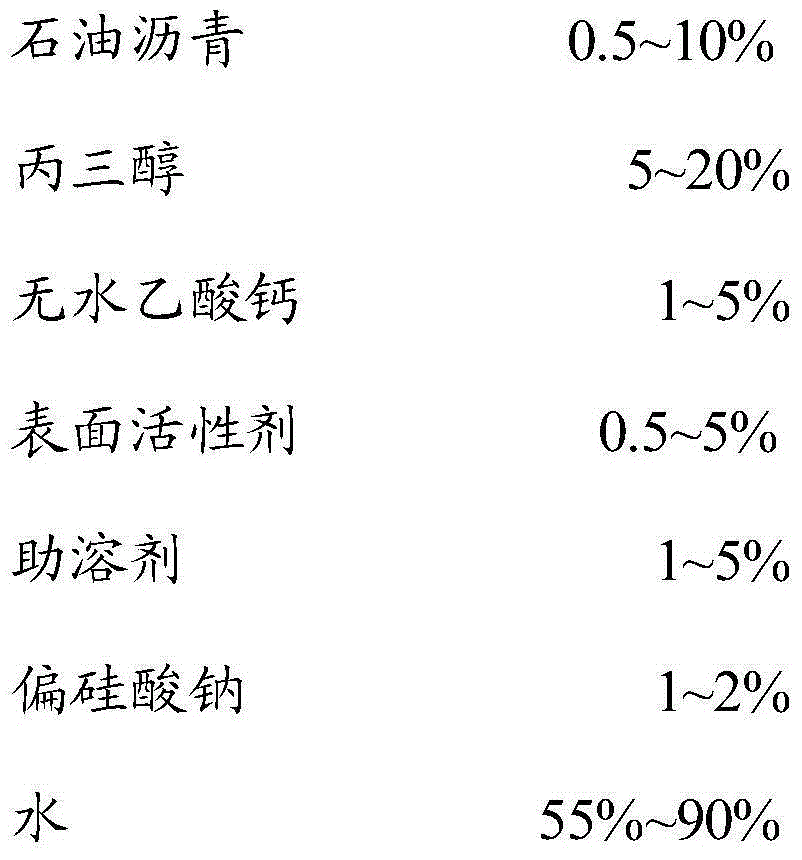

Method used

Image

Examples

Embodiment 1

[0018] Dust Control on Asphalt Pavement

[0019] Add 70% deionized water to the reaction kettle at room temperature, start stirring and heat to 50°C, add 4% anhydrous calcium acetate in batches, add 10% glycerol after completely dissolving, and then add 3 % surface active agent, 8% road asphalt, 3% solubilizer and 2% sodium metasilicate, stir and dissolve until homogeneous, and obtain a brown-dark brown aqueous solution, which is left to stand, cooled, and canned to obtain road dust suppressant finished product.

[0020] The finished road dust suppressant has good moisturizing, moisture absorption and bonding properties, and is mainly used for dust control on asphalt pavement.

Embodiment 2

[0022] Dust Control of Unpaved Soil Pavement in Construction Site

[0023] Add 62% deionized water to the reaction kettle at room temperature, start stirring and heat to 50°C, add 5% anhydrous calcium acetate in batches, add 15% glycerol after completely dissolving, and then add 5% % surface active agent, 8% road asphalt, 4% co-solvent and 1% sodium metasilicate, stirring and dissolving until homogeneous, to obtain a brown-dark brown aqueous solution, standing, cooling, and canning to obtain road dust suppressant finished product.

[0024] The finished product of road dust suppressant has better moisturizing, moisture absorption and bonding properties, and is suitable for unpaved soil roads such as construction sites.

Embodiment 3

[0026] Control of Road Dust in Open Pit Mine Area

[0027] Add 54% deionized water to the reaction kettle at room temperature, start stirring and heat to 50°C, add 5% anhydrous calcium acetate in batches, add 20% glycerol after completely dissolving, and then add 5% % surface active agent, 10% road asphalt, 5% co-solvent and 1% sodium metasilicate, stirring and dissolving until homogeneous, to obtain a brown-dark brown aqueous solution, standing, cooling, and canning to obtain road dust suppressant finished product.

[0028] The finished road dust suppressant has better moisturizing, moisture absorption and bonding properties, and is suitable for the treatment of road dust such as fine-grained coal ash and clay caused by large-scale vehicle rolling in coal yards and open-pit coal mines.

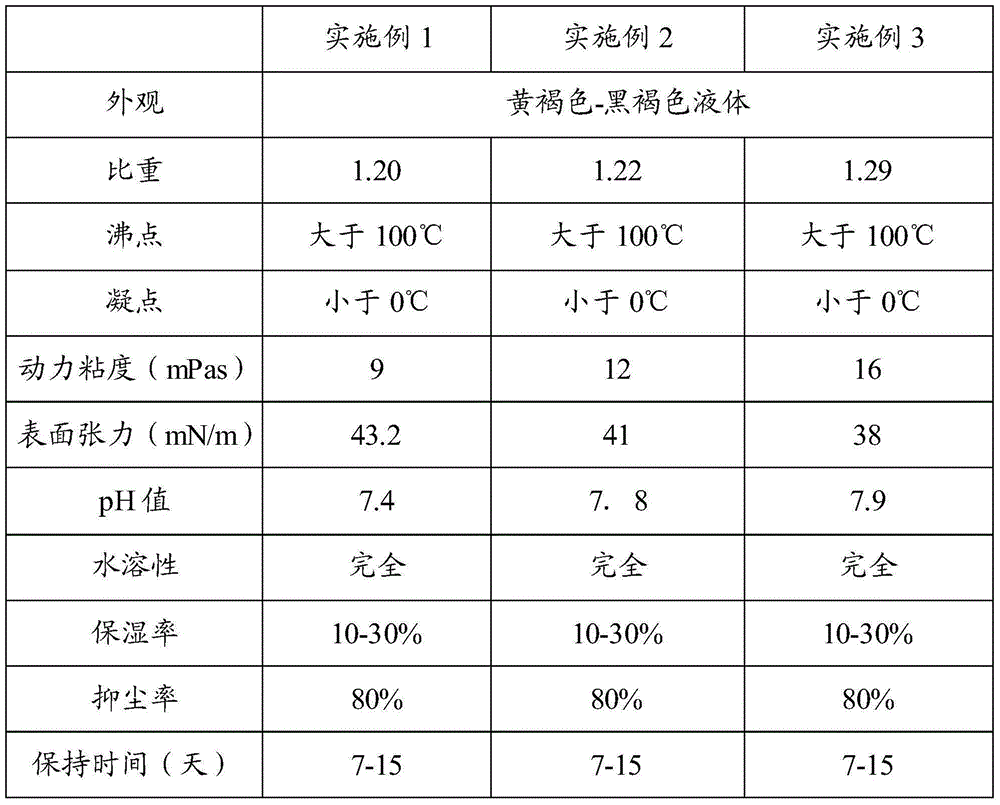

[0029] The main technical indicators of the product of the above embodiment 1~embodiment 3 of the present invention are as follows table 1:

[0030]

[0031] It can be seen from Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com