Patents

Literature

32results about How to "Reduce the hidden dangers of safety accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

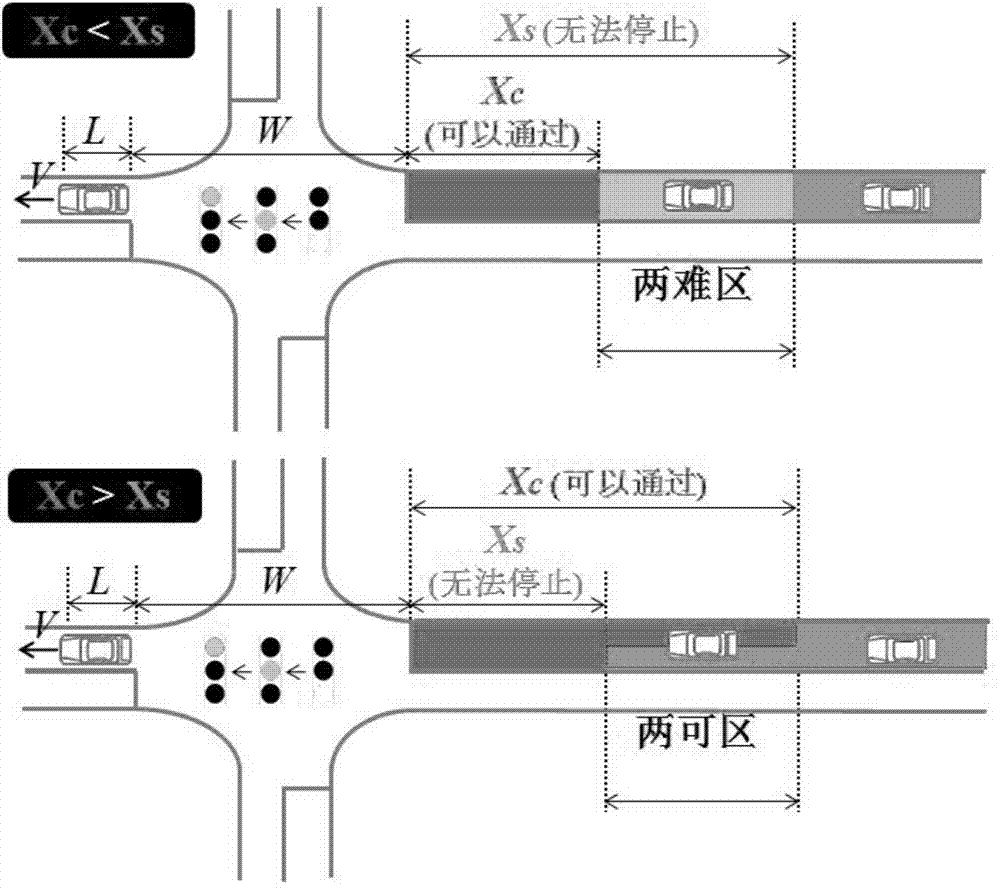

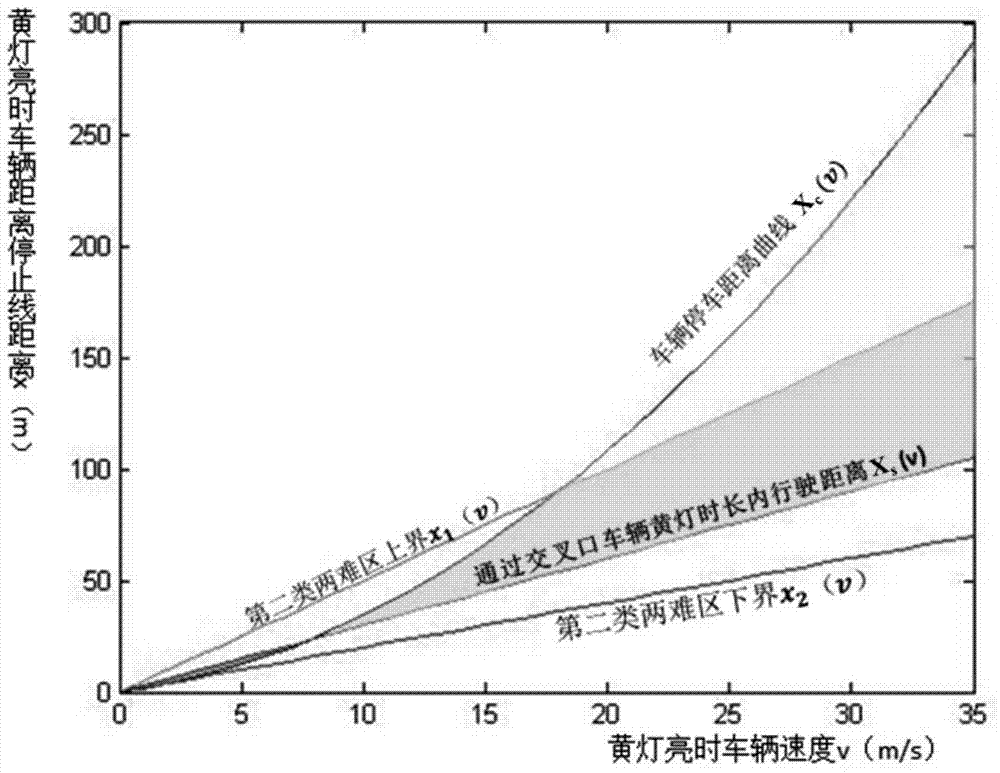

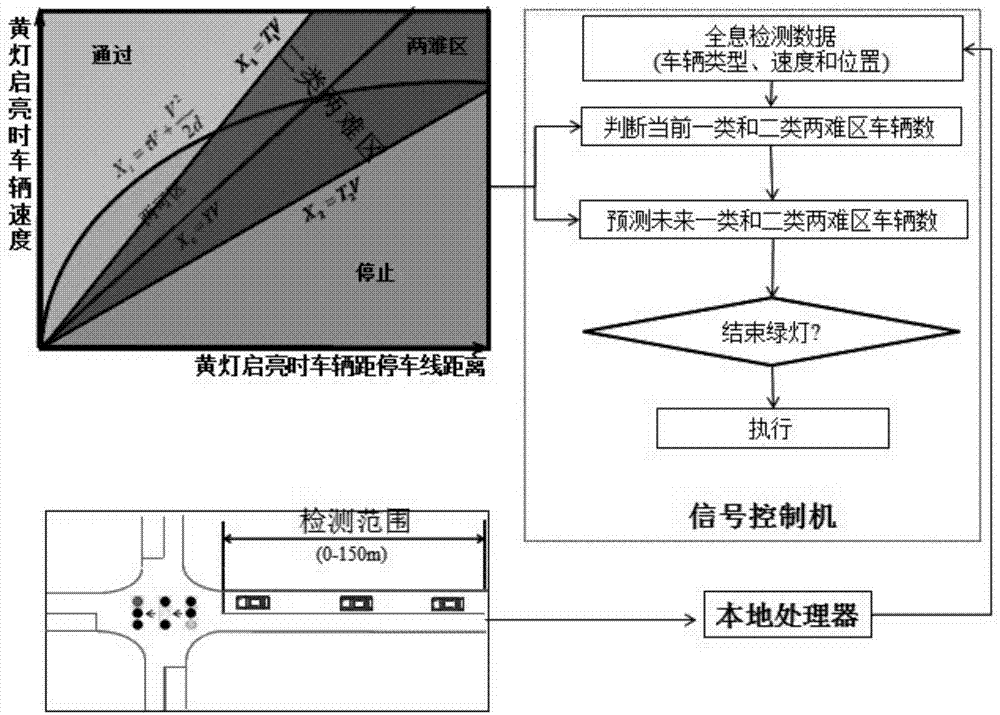

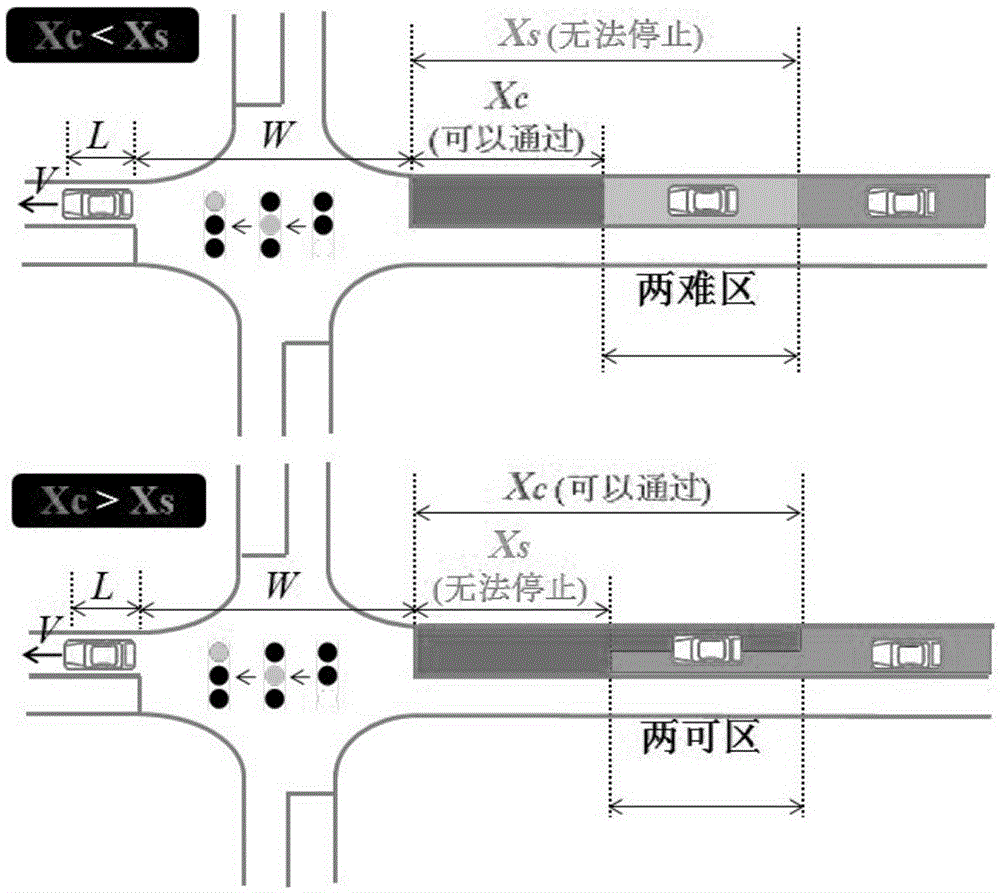

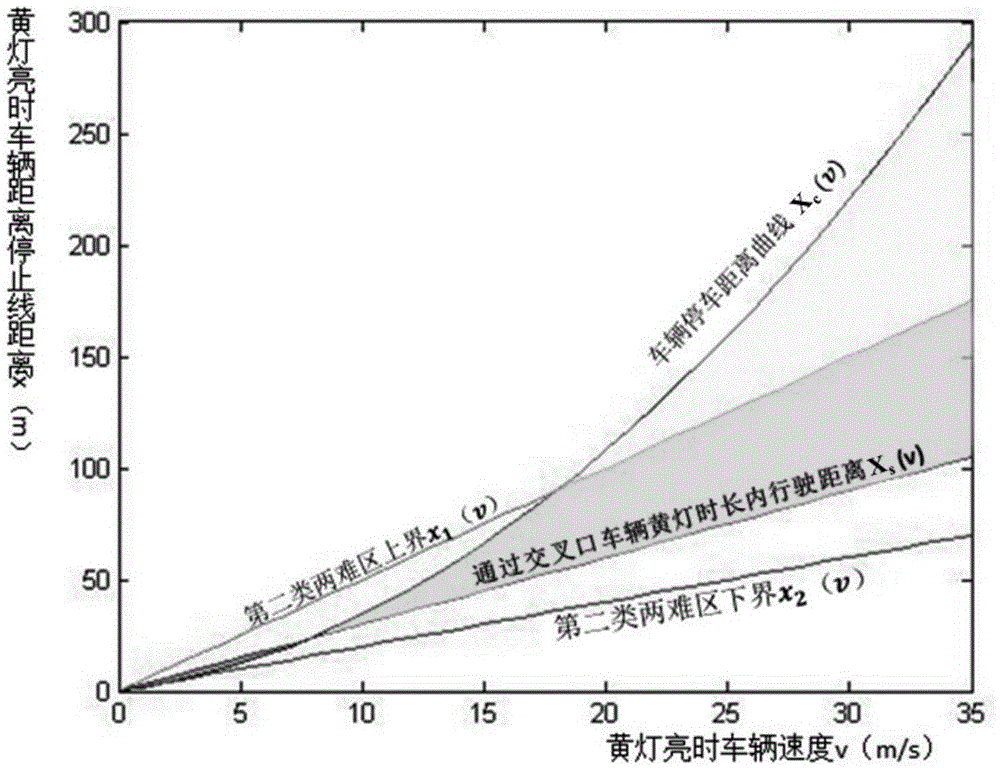

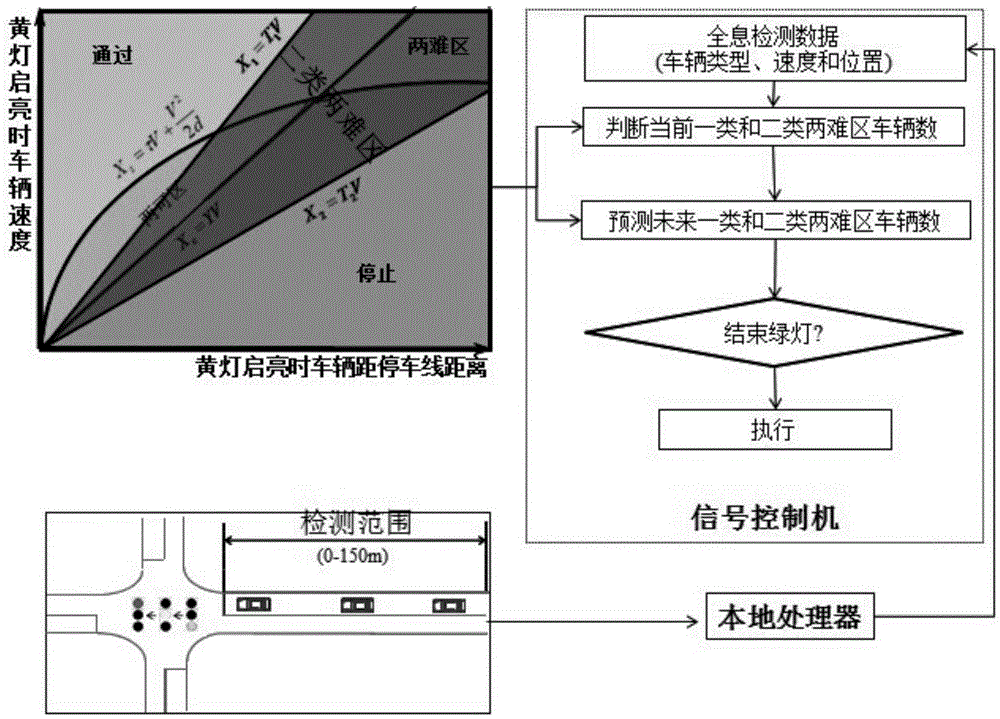

Signalized intersection dilemma region control method based on real-time vehicle track

ActiveCN104282161AReduce the numberReduce the hidden dangers of safety accidentsControlling traffic signalsPhase controlGreen-light

The invention relates to a signalized intersection dilemma region control method based on a real-time vehicle track. The method is characterized by including the following steps that (1) state information of vehicles about to pass an intersection is acquired through a holographic detection device of the intersection; (2) according to the acquired state information of the vehicles about to pass the intersection, signal phase control of the intersection is conducted, and whether green light time needs to be prolonged or not is determined according to the acquired number of the vehicles located in a first dilemma region and a second dilemma region at the current moment and prediction of the number of the vehicles located in the first dilemma region and the second dilemma region at the next moment. Compared with the prior art, the method has the advantages of being high in safety, easy to implement, advanced and the like.

Owner:TONGJI UNIV

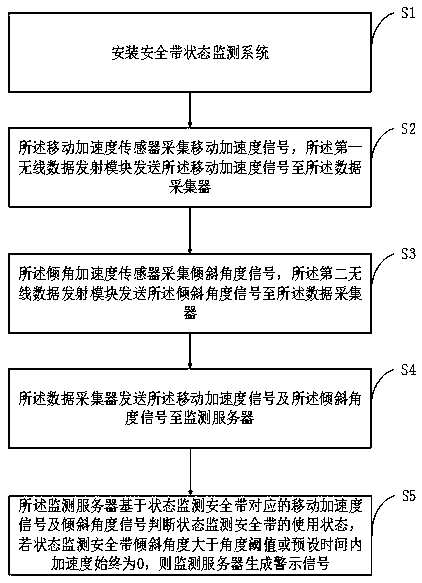

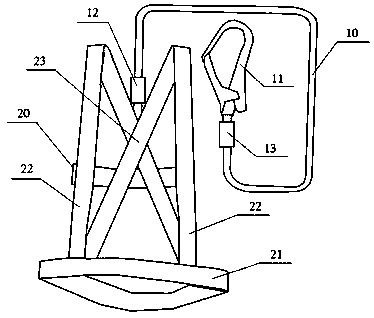

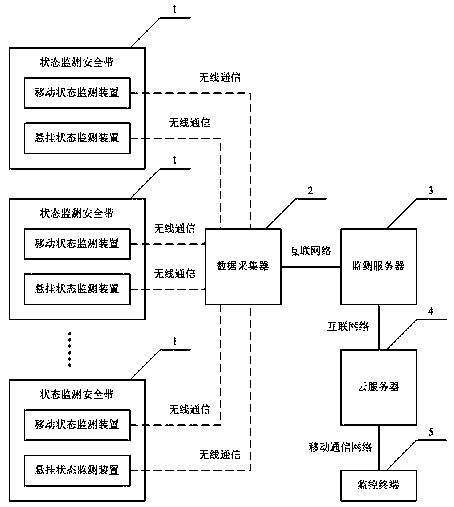

Monitoring method for safety belt status

InactiveCN109613298AImprove securityEasy to manageSafety beltsAcceleration measurementMonitoring systemData collecting

The invention discloses a monitoring method for the safety belt status. The monitoring method for the safety belt status comprises the following steps that a safety belt status monitoring system is installed; an accelerated speed sensor is moved to collect moving accelerated speed signals; inclination angle signals are collected by an inclination angle accelerated speed sensor; the moving accelerated speed signals and the inclination angle signals are sent by a data collecting machine to a monitoring server; and the use status of a status monitoring safety belt is judged by the monitoring server and based on the moving accelerated speed signals and the inclination angle signals corresponding to the status monitoring safety belt, and if the inclination angle of the status monitoring safetybelt is greater than an angle threshold value or the accelerated speed in a preset time is always zero, the monitoring server generates warning signals. According to the monitoring method for the safety belt status, the use status of the safety belt can be monitored to assist to improve the safety supervision and management of safety belt wearing and using condition of operational personnel and help to further reduce the potential safety accident risks of the operational personnel during operation high above the ground.

Owner:CHINA METALLURGICAL CONSTR ENG GRP +2

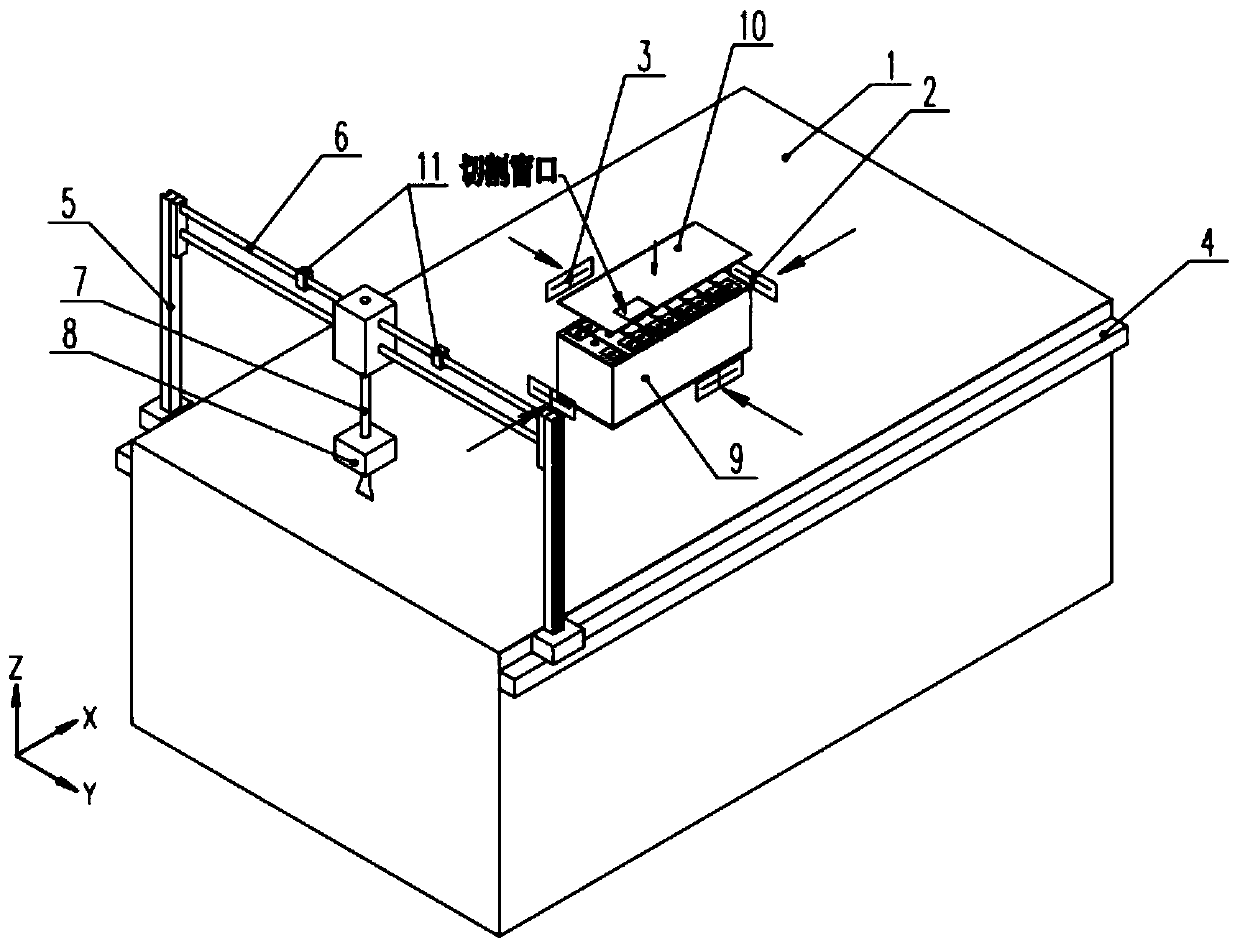

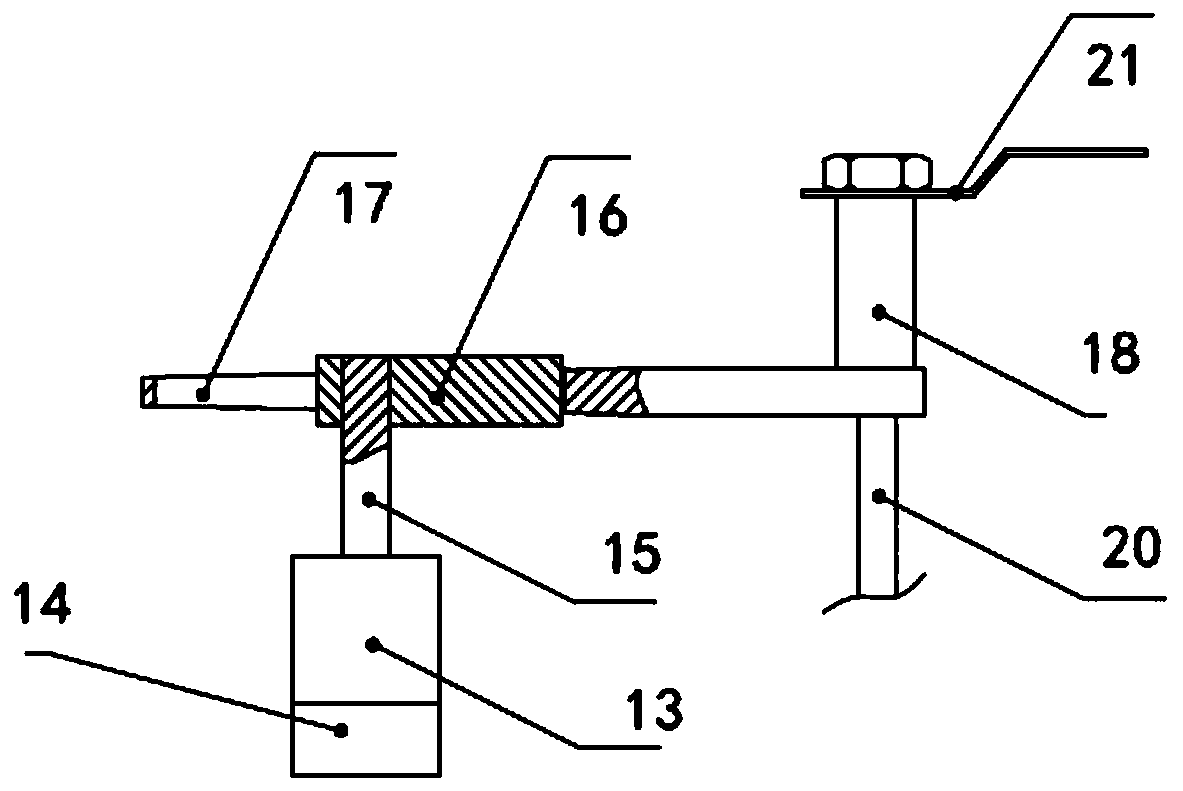

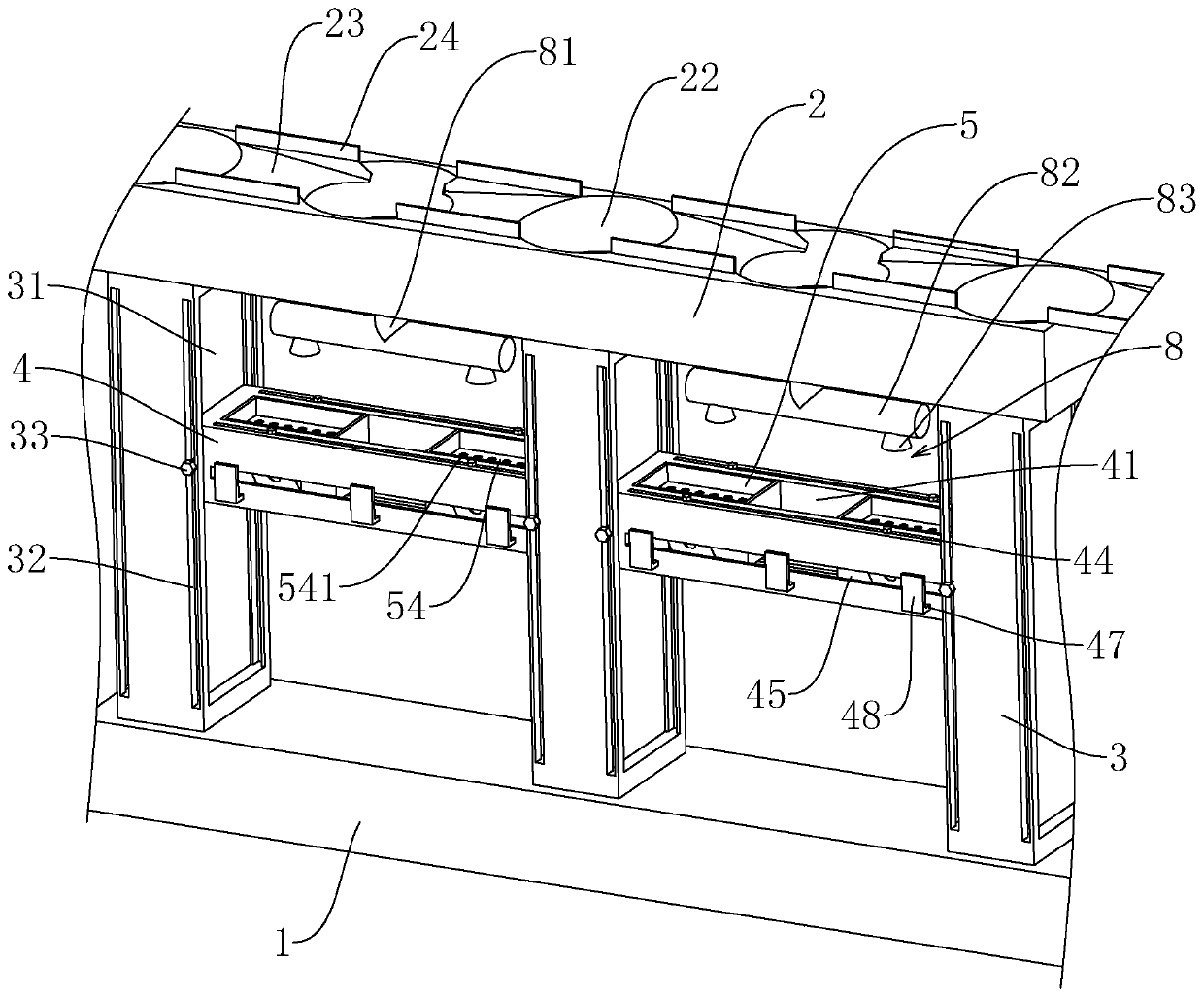

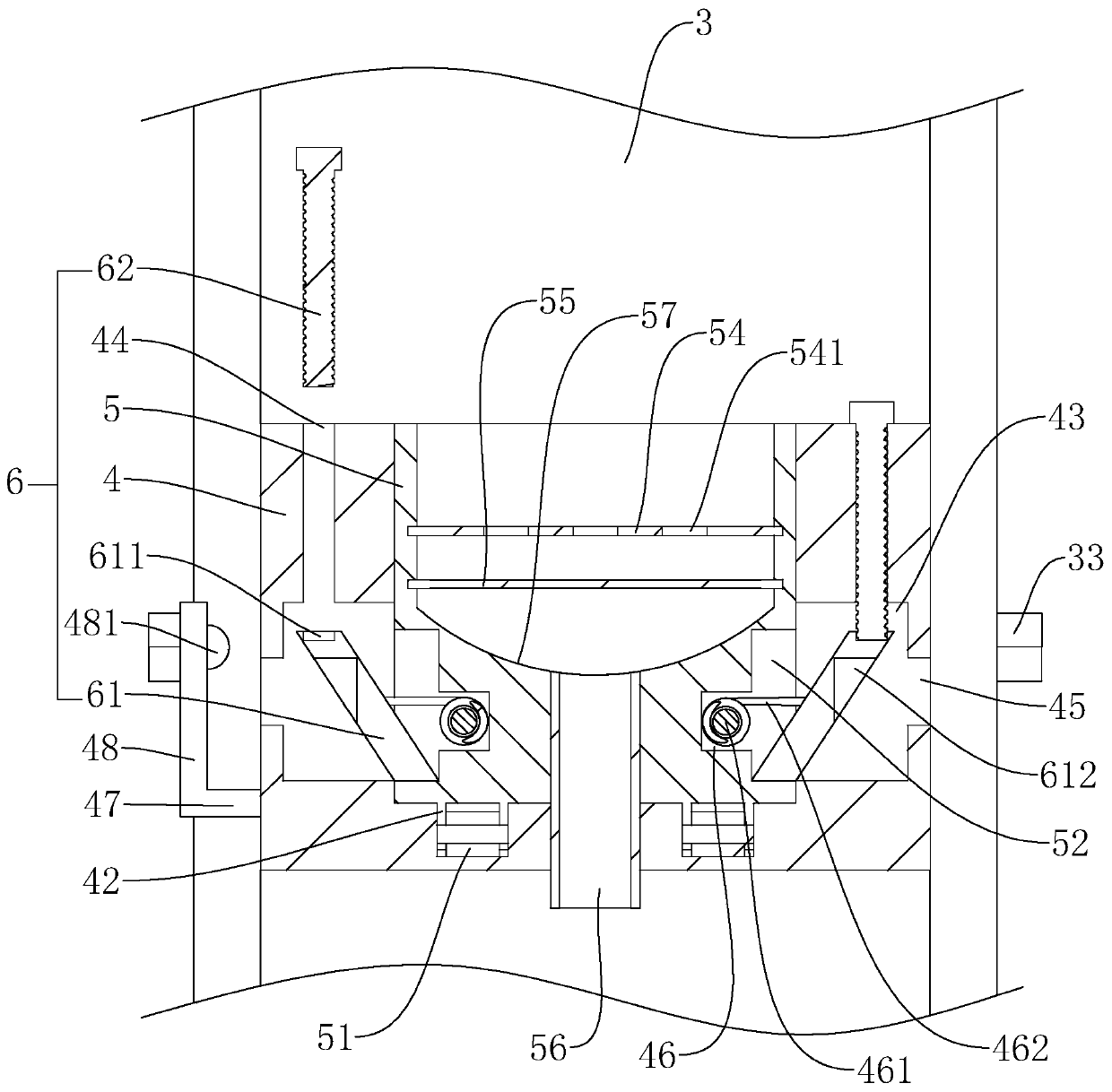

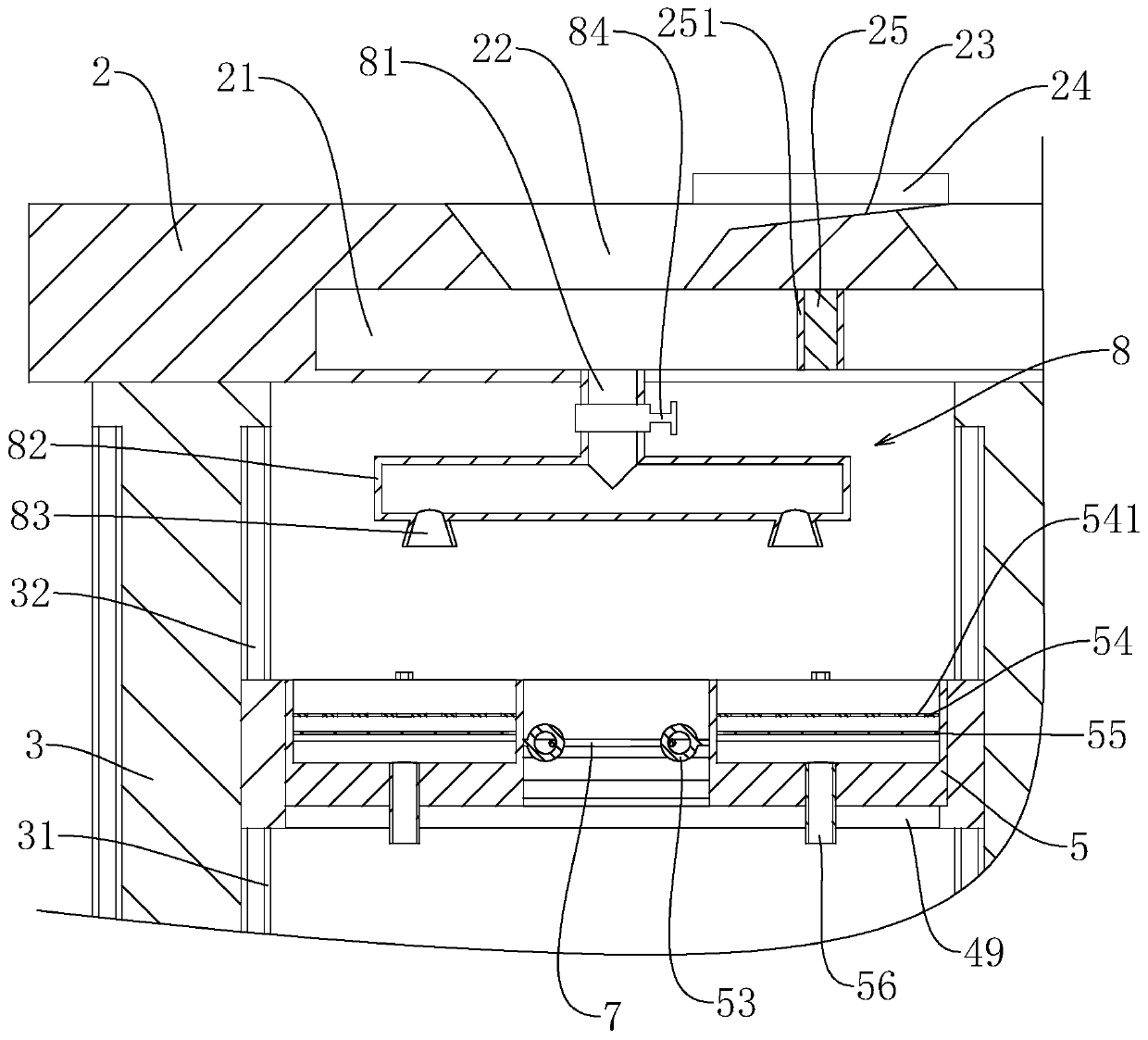

Disassembling device and method for decommissioned power batteries

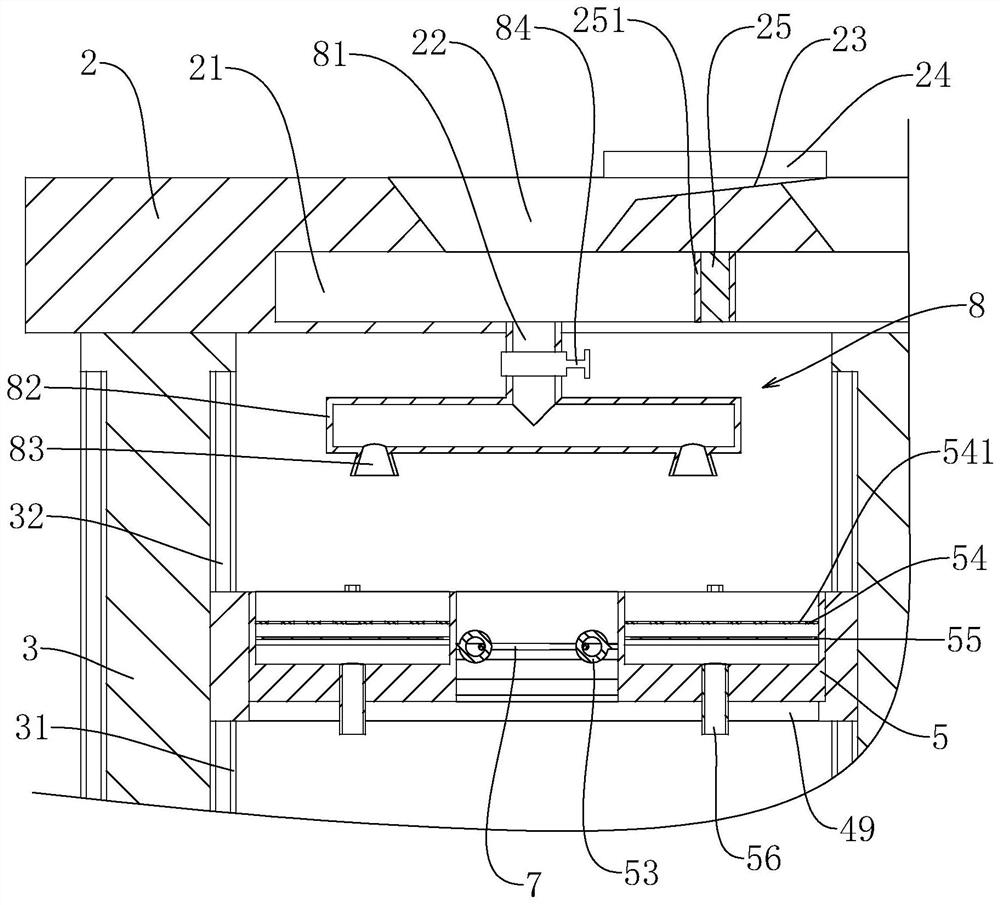

PendingCN110860740AAvoid operational riskLow costWaste accumulators reclaimingLarge fixed membersPower batteryElectrical battery

The invention discloses a disassembling device and method for decommissioned power batteries. The device comprises a workbench, wherein two movable workpiece positioning sliding blocks are arranged ateach of the X-axis direction and the Y-axis direction of the workbench, and the workpiece positioning sliding blocks are used for locking and fixing battery packs or battery modules; a portal frame capable of sliding in the X-axis direction is arranged on the workbench and is used for adjusting a cutting module in the X-axis direction; a first sliding rail is fixed to the portal frame in the Z-axis direction, a second sliding rail and a third sliding rail are fixed in the Y-axis direction, two limiting sliding blocks are arranged on the second sliding rail, and the cutting module fixed on thesecond sliding rail and the third sliding rail is arranged between the two limiting sliding blocks. According to the disassembling device and method for the decommissioned power batteries, reciprocating vibration type cutting is adopted to replace mechanical rotary type cutting for disassembling the decommissioned power batteries, and the technical problem that in the prior art, due to the fact that a mechanical rotary type tool has large rotating inertia, and is not easy to control, a grinding wheel sheet or a steel saw blade is damaged and flown off very easily when operation is slightly careless, and certain potential safety hazards exist is solved.

Owner:珠海瓦特电力设备有限公司 +1

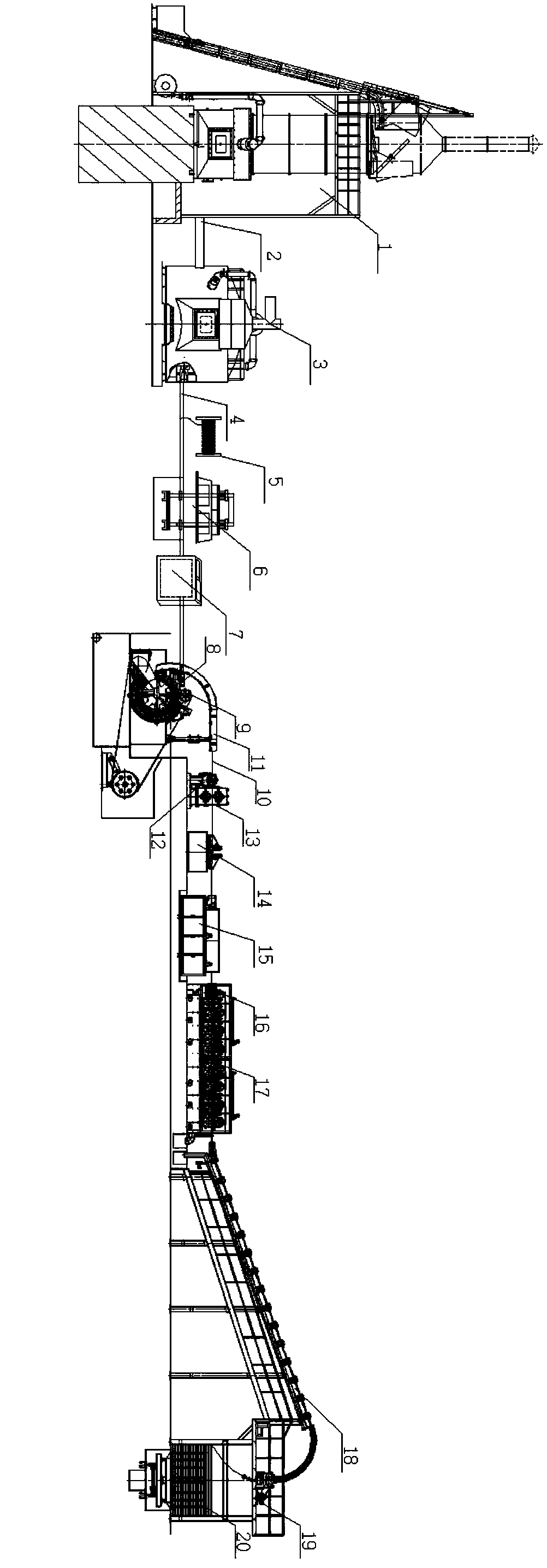

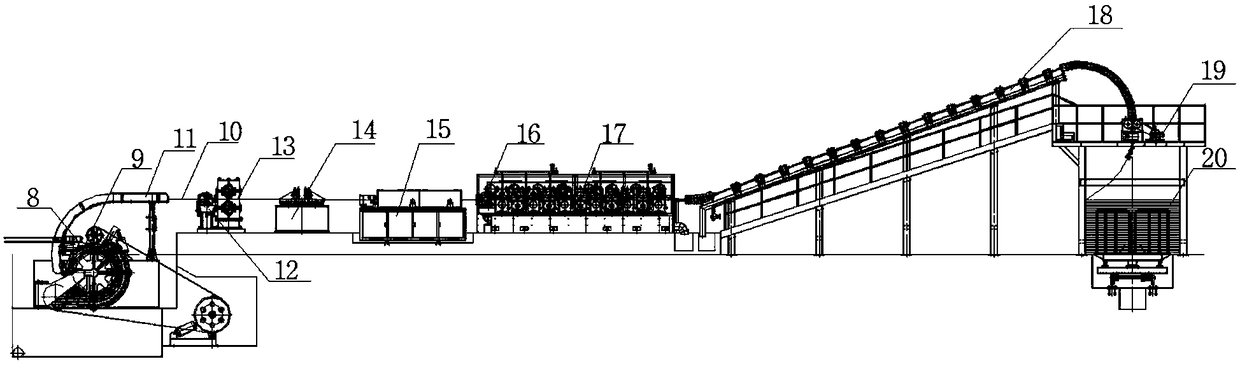

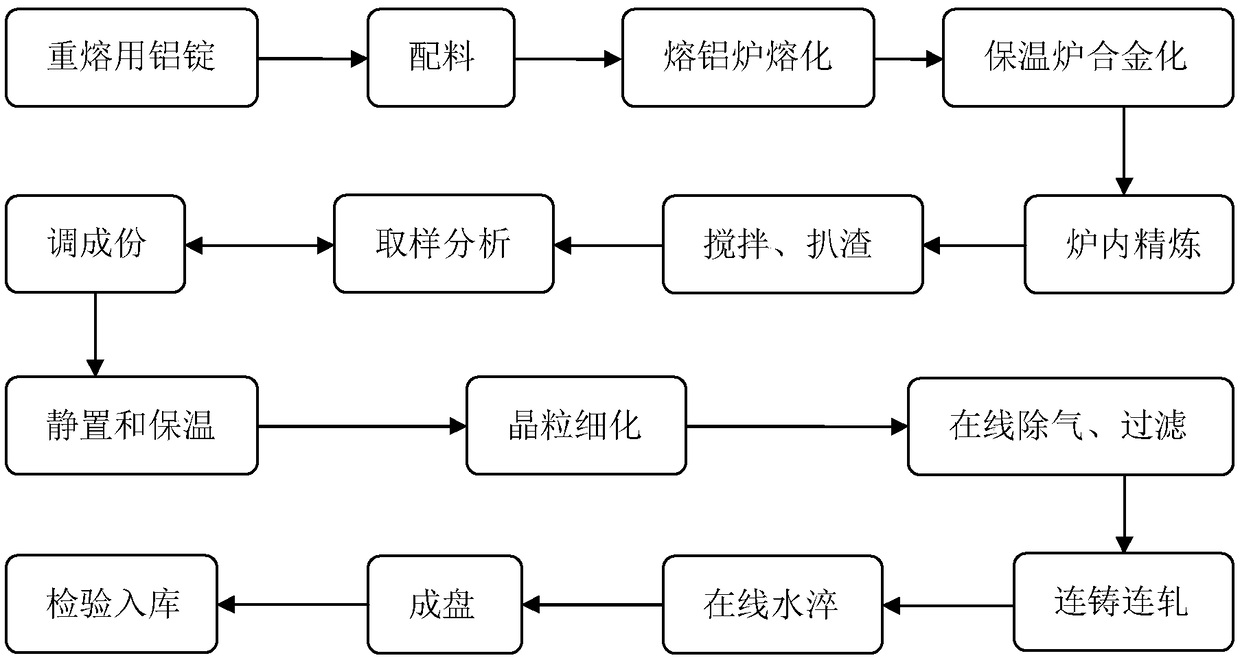

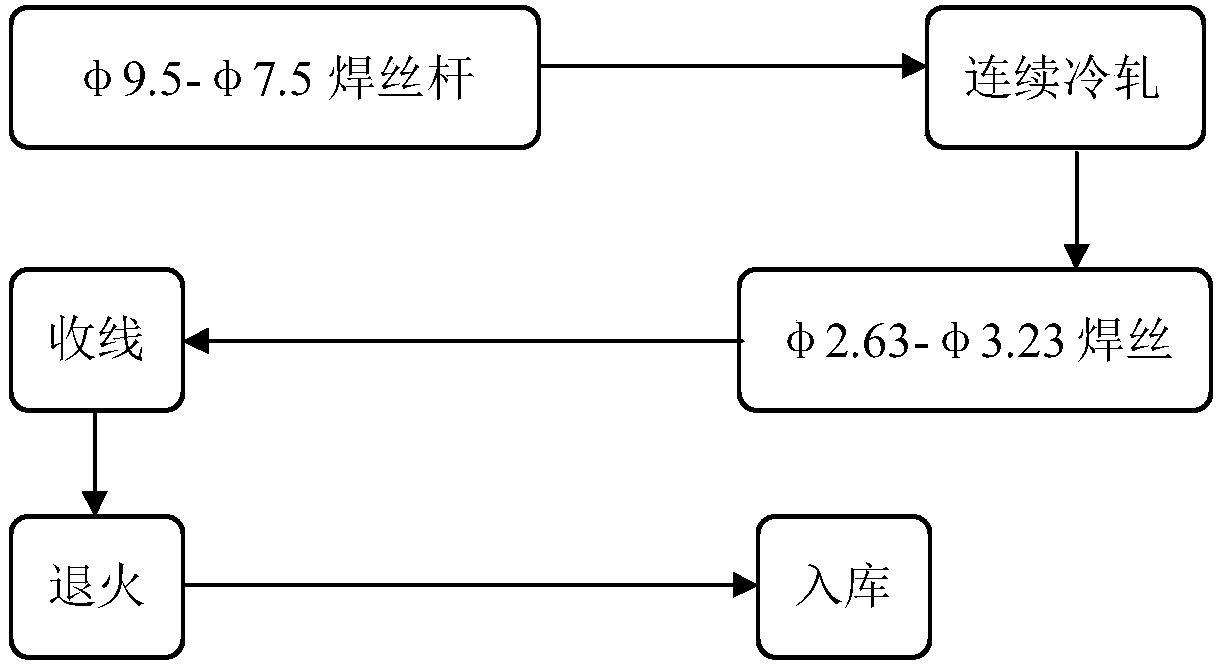

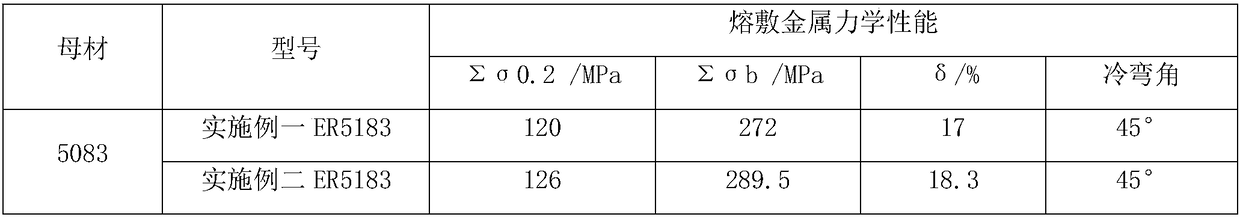

Continuous casting and rolling method for preparing wire rod for 5183 aluminum alloy welding wire

The invention relates to a continuous casting and rolling process for a wire rod for an aluminum alloy welding wire, in particular to a continuous casting and rolling method for preparing a wire rod for a 5183 aluminum alloy welding wire. The continuous casting and rolling method for preparing wire rod for 5183 aluminum alloy welding wire comprises the steps that (1) burdening is carried out; (2)smelting is carried out; (3) melt is subjected to purification, including degassing, impurity removing, drossing, covering agent spraying, and warm keeping and standing; (4) continuous casting is carried out to prepare aluminum alloy wire ingots; (5) continuous rolling is carried out to obtain an aluminum alloy wire rod; (6) and the aluminum alloy wire rod without oil-water quenching guide rod iscarried out to form a circle by double frames. The continuous casting and rolling method for preparing 5183 aluminum alloy wire rod has the advantages of high production efficiency, moderate cost, stable wire rod quality, hydrogen content less than or equal to 0.12 ml / 100 g, and excellent mechanical properties.

Owner:江苏和拓铝线有限公司

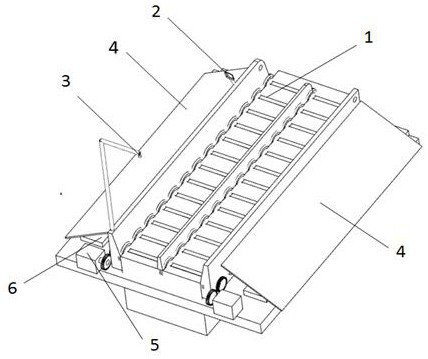

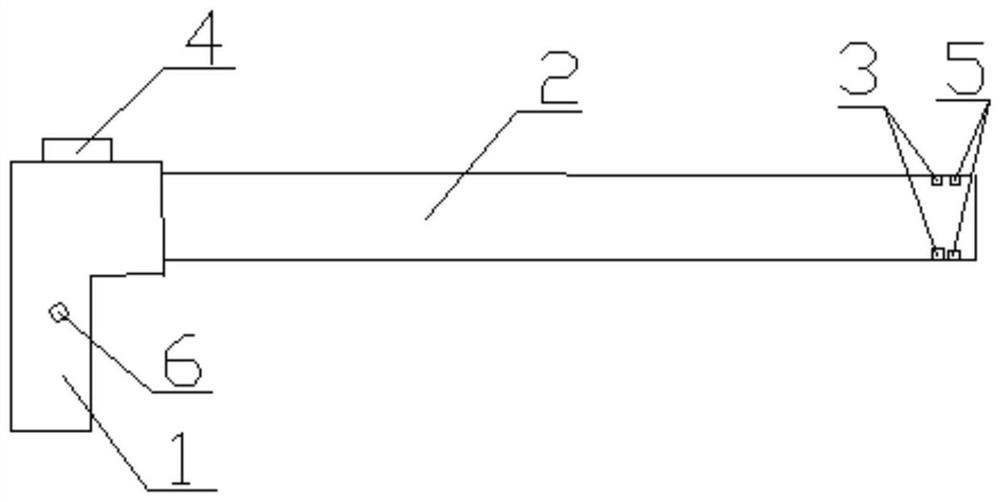

Line safety patrolling device and using method thereof

ActiveCN111071442AReduce the hidden dangers of safety accidentsEasy to move forwardRemote controlled aircraftCable installation apparatusWireless transmissionUncrewed vehicle

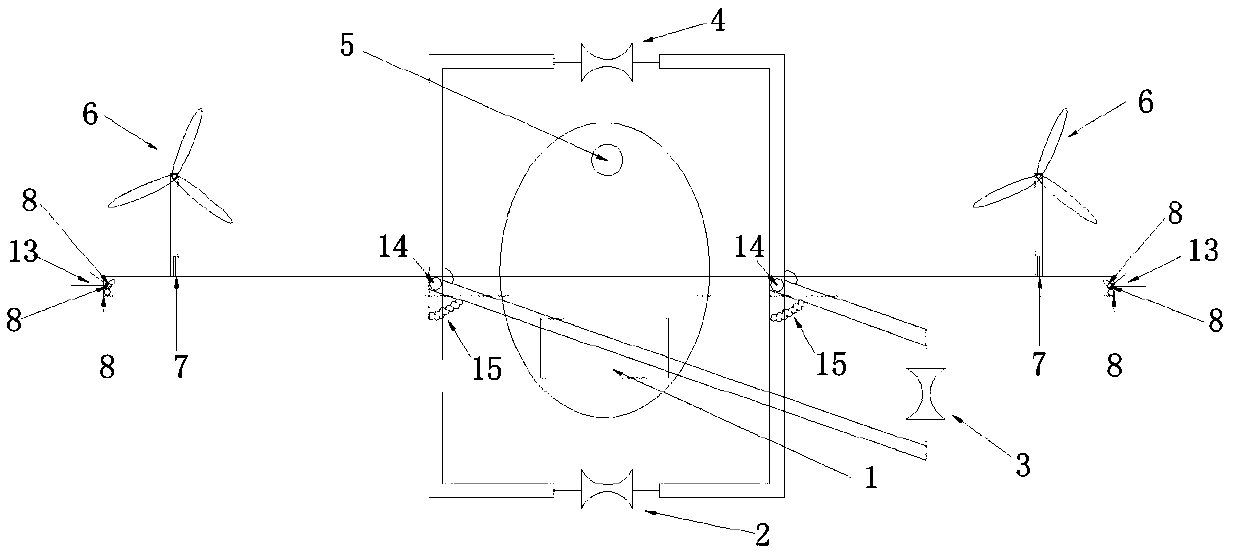

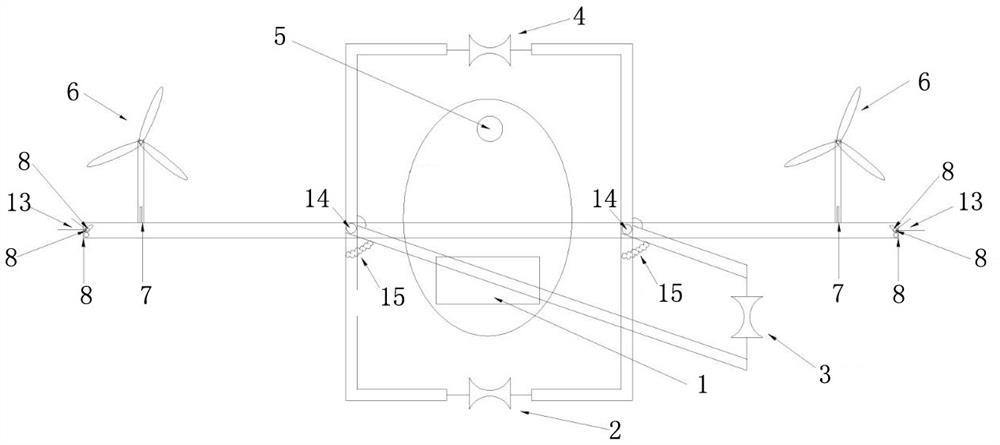

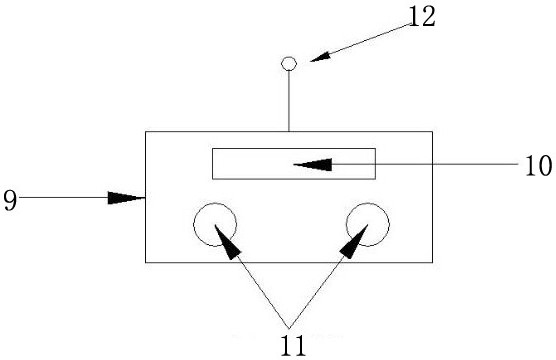

The invention relates to a line safety patrolling device and a using method thereof, and belongs to the technical field of electric power protection. The line safety patrolling device comprises a remote controller part and a main body part, the remote controller part and the main body part are connected in a matched mode through wireless transmission signals, and the main body part comprises an unmanned aerial vehicle body, a tumbler type concave wheel rail car, a propeller (6), a propeller motor (7) and an infrared distance measuring probe (8). The line safety patrolling device can lift off and accurately land on a wire, and can advance on the wire conveniently to patrol the line, distance measurement is carried out on trees outside a 10 kV line protection area and offline trees in normalweather, trees endangering the line safety are found in time, data is provided for owners of the trees, a hidden danger notice is issued, the owners of the trees are coordinated to conduct trimming and felling, line section inspection tour is conducted when a special weather failure occurs and a gate falls off, the probability that personnel cross crops and gullies is reduced, personnel safety accident hidden danger is reduced, failures are effectively found, and power failure time is shortened.

Owner:STATE GRID JIBEI ELECTRIC POWER CO LTD TANGSHAN POWER SUPPLY CO +1

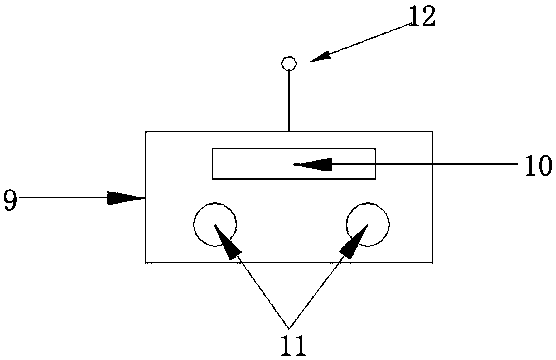

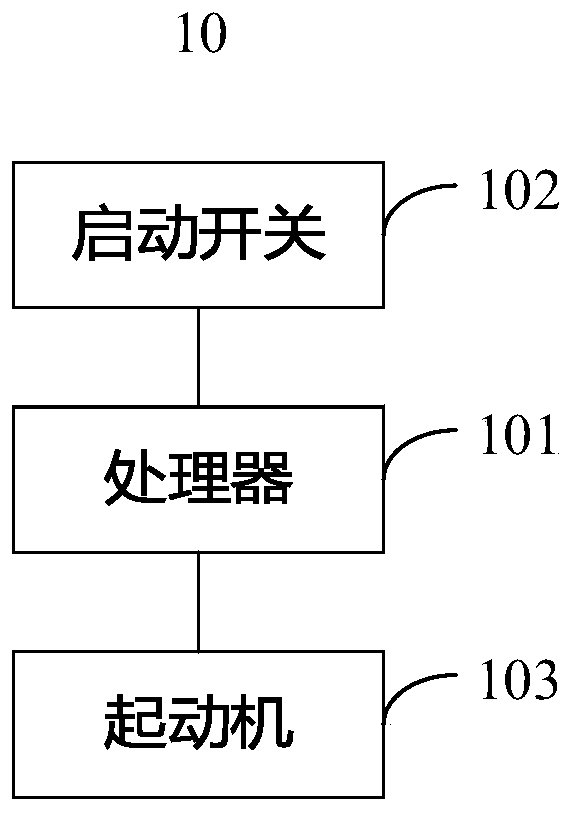

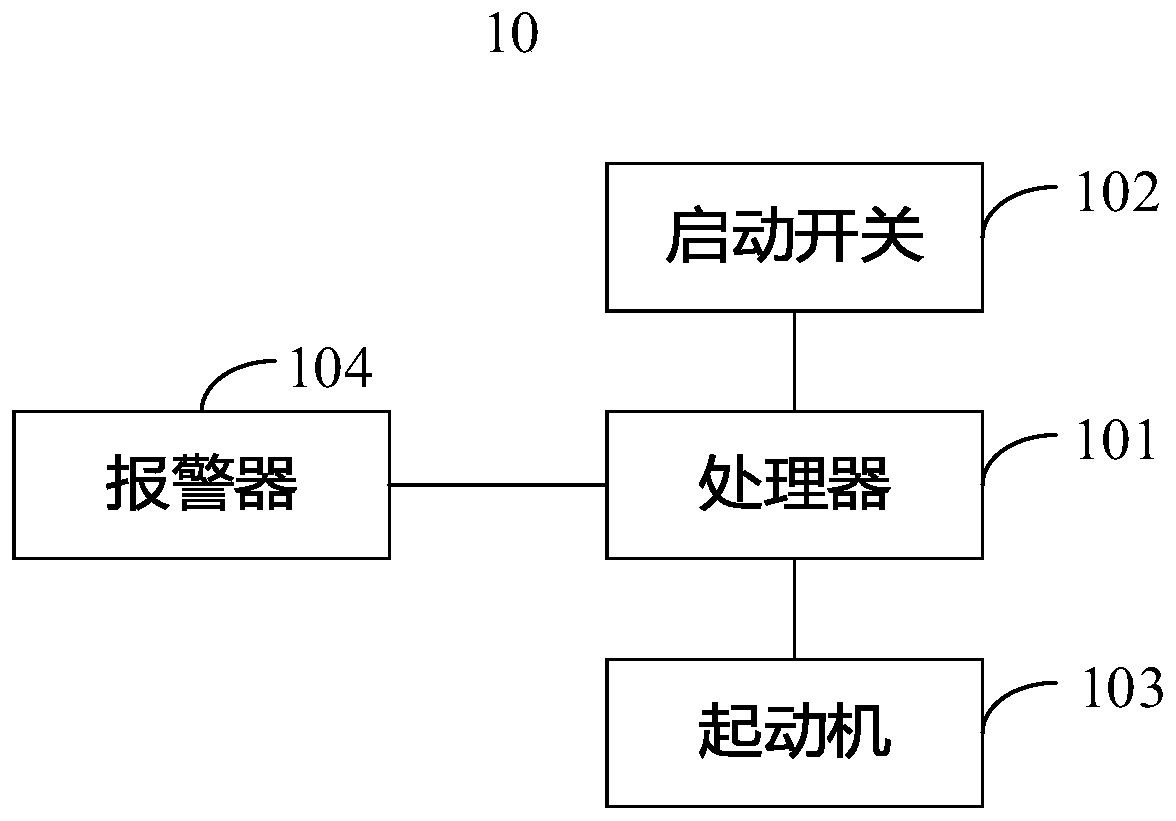

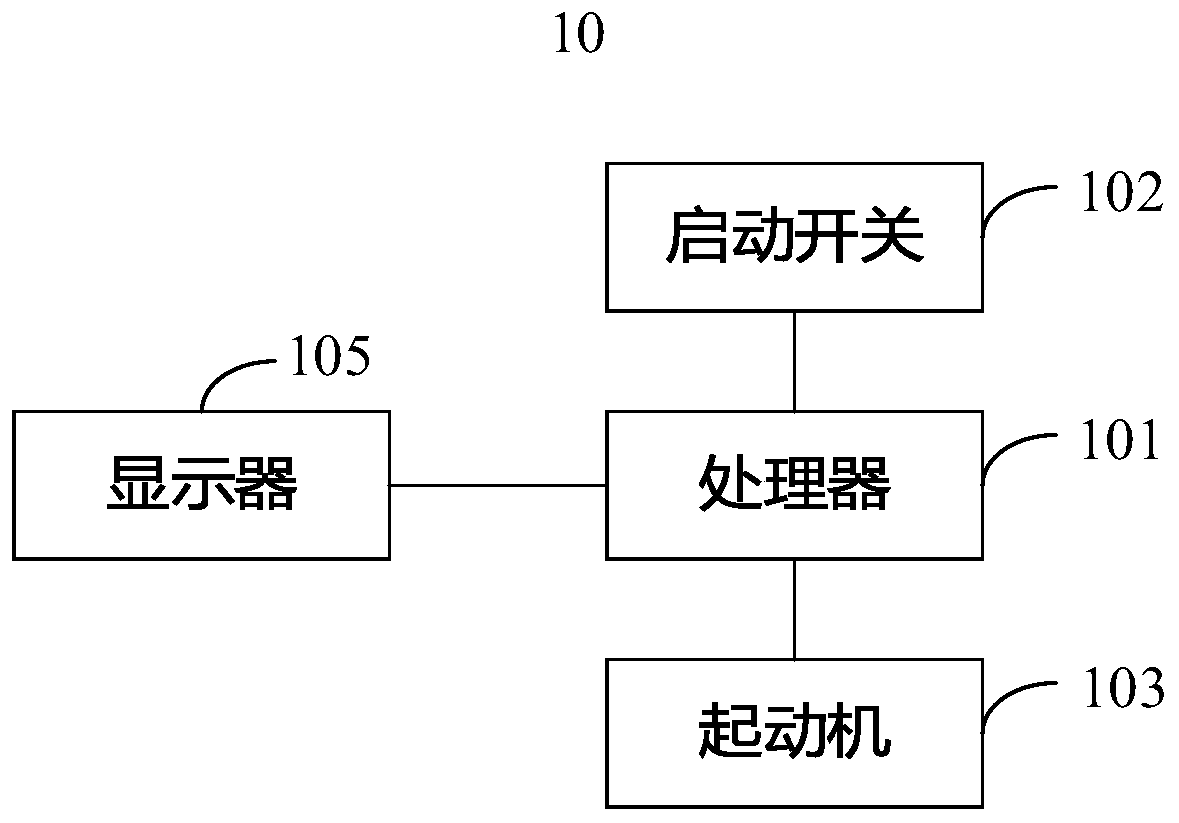

Starting protection system and mechanical device

InactiveCN110397540AAvoid double bootEnsure safetyInternal combustion piston enginesElectric motor startersProtection systemElectrical and Electronics engineering

The application provides a starting protection system and a mechanical device. The starting protection system acquires rotation speed of an engine through a processor, and stops sending trigger signals when the rotation speed is larger than preset first rotation speed, and when continuous starting signal receiving time of the processor is larger than preset first time and the rotation speed is less than or equal to the preset first rotation speed, the trigger signal sending stop mode is adopted, and therefore repeated starting of a starter is avoided, long time work of the starter is avoided,safety of the starter is guaranteed, and safety accident hidden danger is reduced.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

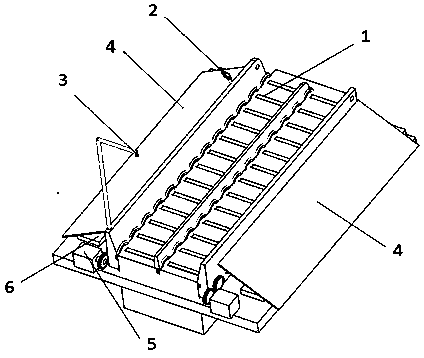

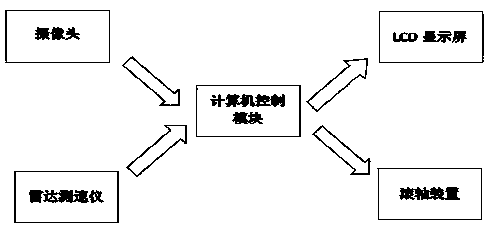

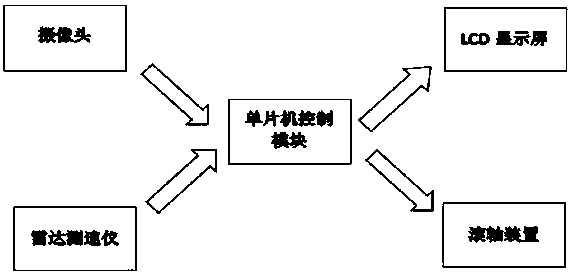

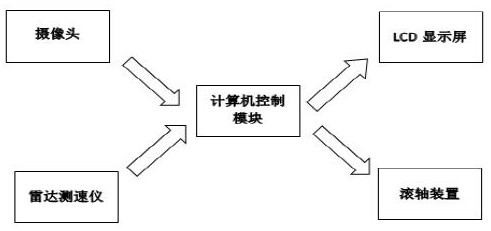

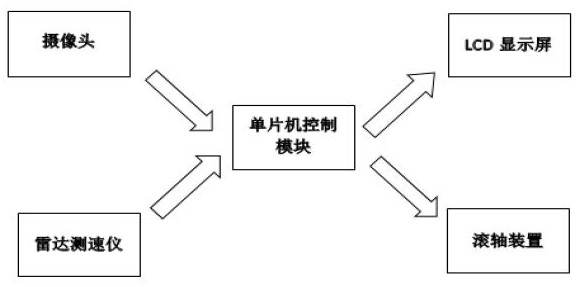

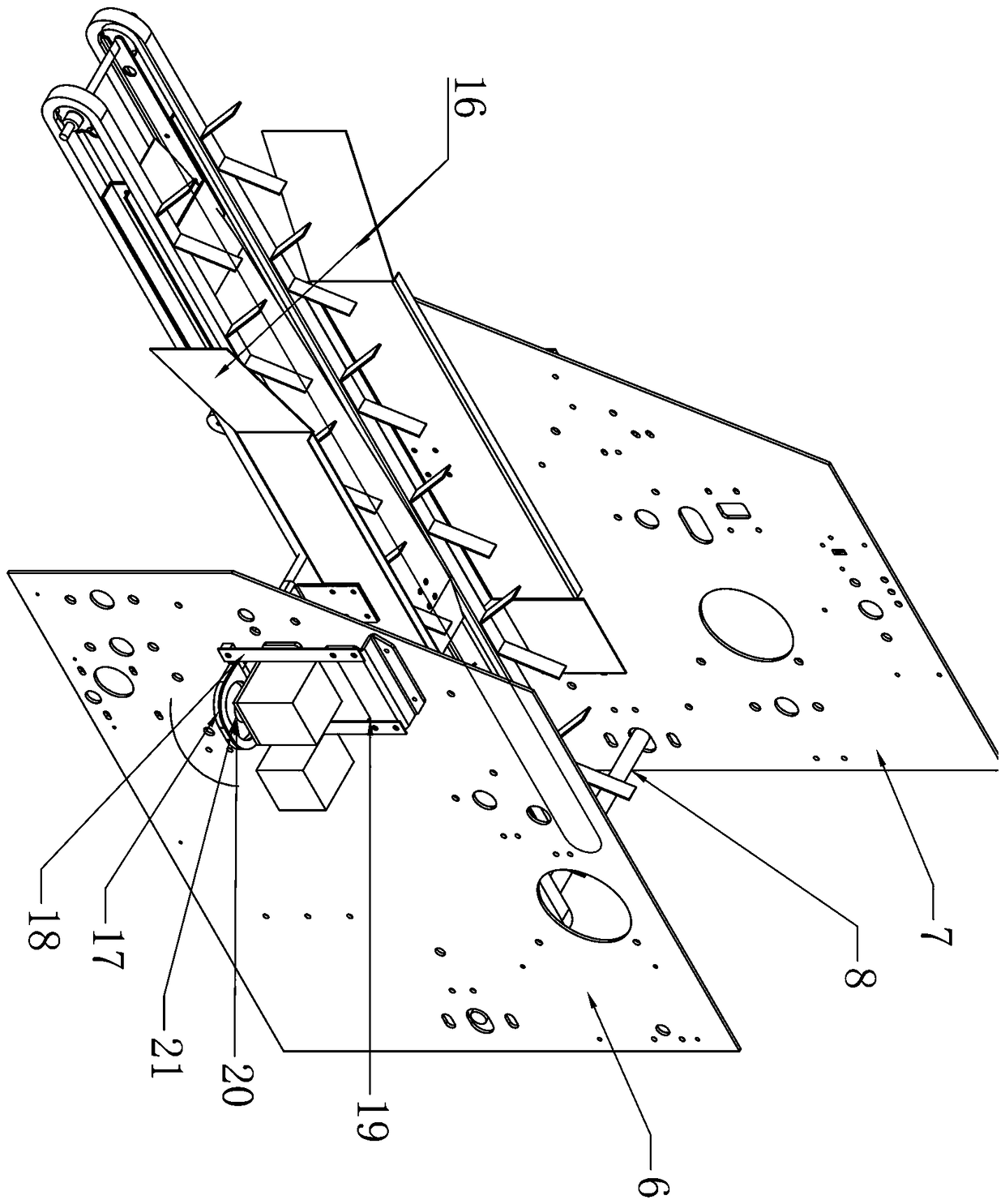

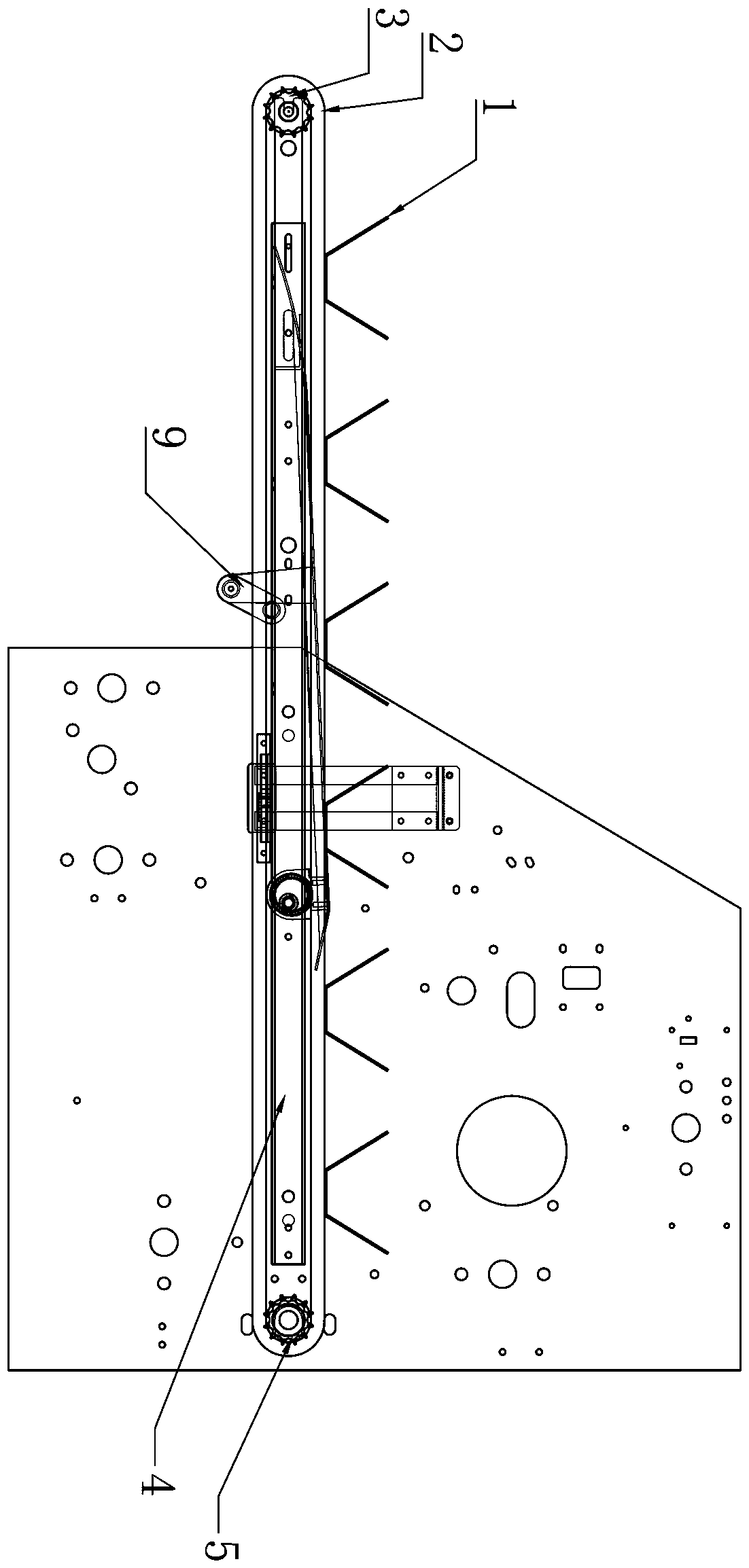

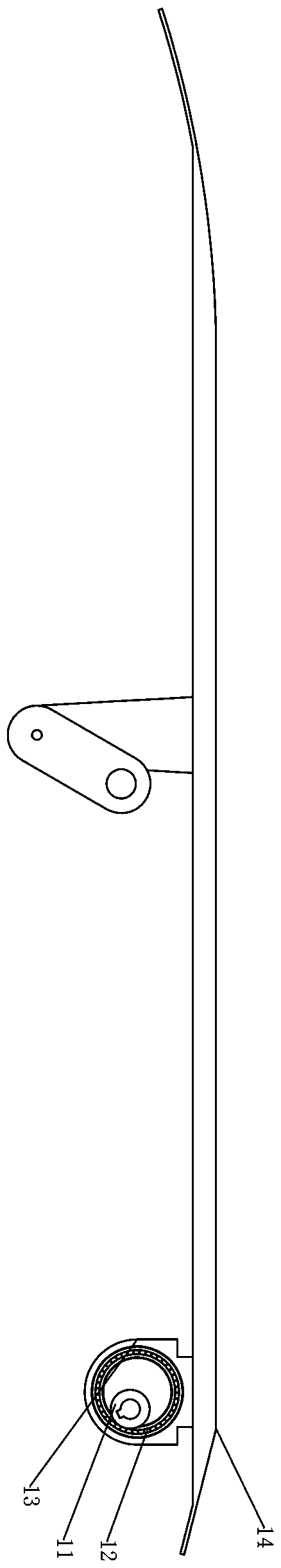

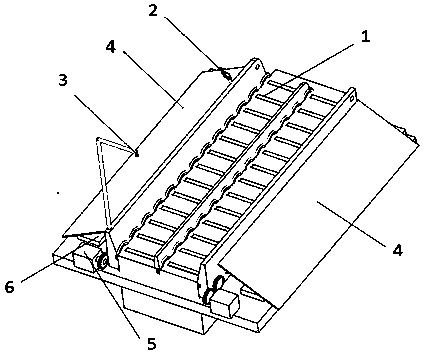

Auxiliary device for vehicle uphill and downhill

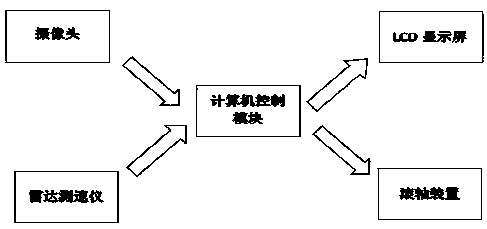

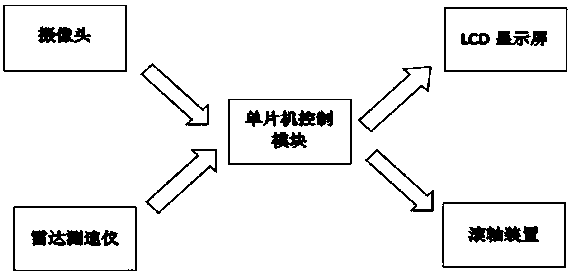

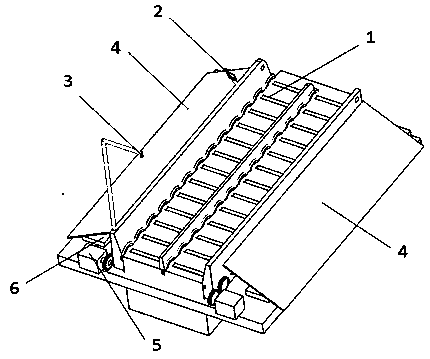

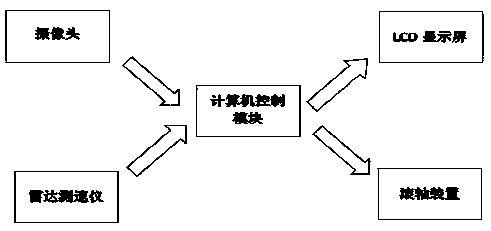

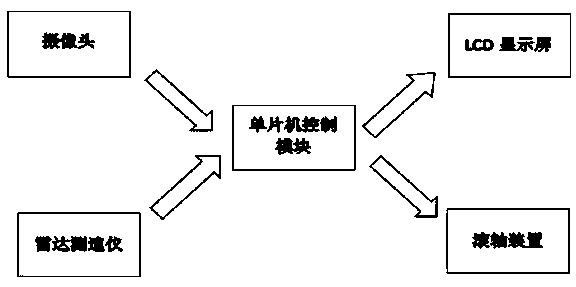

ActiveCN108486981AReduce speedImprove securityTemporary pavingsComputer moduleGenerators (Apparatus)

The invention designs an auxiliary device for vehicle uphill and downhill. The auxiliary device for the vehicle uphill and downhill comprises roller devices, a damping wheel, a position and speed detection device, a solar panel, an electric generator device, a storage battery, a LCD display screen, a controller module. The roller devices, the damping wheel, the position and speed detection device,the solar panel, the electric generator device, the storage battery and the LCD display screen are all connected with the controller module. When a vehicle passes an uphill road, the roller devices provide the forward power for the vehicle by rotating, and the vehicle can be prevented from slipping back. When the vehicle passes through the roller devices, arranged side by side, on a downhill roadsurface, the position and speed information of the vehicle is detected by the position and speed detection device, the controller displays the speed on the LCD display screen; the greater the speed,the greater the damping of the damping wheel on the roller devices; and if the vehicle speed exceeds a certain threshold, the auxiliary device is simple in structure design, is more effective than a general uphill and downhill auxiliary device, and the effect is better.

Owner:温州品力智能幕墙门窗有限公司

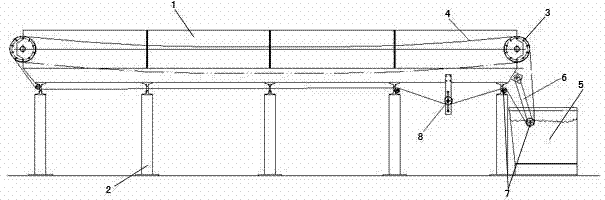

Filtration fabric recycling utilization device for copper alloy production line

InactiveCN103877774AReduce labor intensityReduce pollutionMoving filtering element filtersProduction lineFiltration

The invention discloses a filtration fabric recycling utilization device for a copper alloy production line. The device comprises a filter and a supporting bracket for supporting the filter. The inlet end and the outlet end of the filter are provided with a pair of transmission rollers, a filtration fabric drives the transmission rollers, and the filtration fabric and the transmission rollers are lapped to form an circulation belt; a copper oxide recycling bin is arranged below the outlet end of the filter, a rotating arm connected with the filter is arranged above the copper oxide recycling bin, a guide wheel is arranged at the lower end of the rotating arm and reaches into the copper oxide recycling bin; a gravity tension pressing wheel is fixedly arranged right below a position, near an outlet, on the filter, guide wheels are arranged on the top end of the supporting bracket at both sides of the gravity tension pressing wheel and on the supporting bracket supporting the inlet end of the filter, and the filtration fabric drive the guide wheels, the gravity tension pressing wheel and the transmission rollers. The device provided by the invention has the advantages of saving the cost, reducing the labor intensity, eliminating potential risks of safety accidents because of no need of hoisting and pulling by a travelling crane and artificial beating, and reducing the pollution caused by abandoned filtration fabrics.

Owner:宜兴市意达铜业有限公司

Greening barrier device for bridge

ActiveCN111576208AReduce visual fatigueSave resourcesGeneral water supply conservationSelf-acting watering devicesFastenerStormwater

The invention relates to the technical field of bridge engineering and discloses a greening barrier device for a bridge. The device comprises a bottom plate, a top plate located right above the bottomplate, and a plurality of stand columns fixed between the bottom plate and the top plate and parallel to one another. A base is connected between any two adjacent stand columns, a sliding groove extending in a length direction is arranged in an upper end surface of the base, a plurality of planting boxes used for planting ornamental plants are connected into the sliding groove in a sliding mode,and the planting boxes are positioned through fasteners. The top plate is provided with a water collecting cavity for storing rainwater and an irrigation part for spraying water in the water collecting cavity to the planting boxes, and the inner wall of the upper side of the water collecting cavity is provided with a water leakage hole for rainwater to flow in; and a drainage pipe is connected tothe bottom of each planting box, a drainage hole extending in the length direction is arranged in the bottom wall of the sliding groove, the drainage pipe is slidably connected into the drainage hole,and one end of the drainage pipe penetrates out of the base. The device has an effect of effectively reducing visual fatigue of a driver during driving.

Owner:浙江常青公路工程有限公司

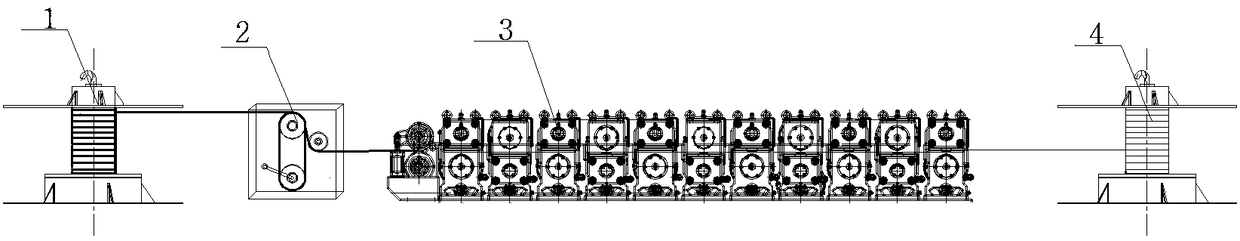

Machining process of 5183 aluminum alloy semi-finished welding wire

InactiveCN108340098AGuarantee product qualityReduce consumptionWelding/cutting media/materialsSoldering mediaWire rodWork in process

The invention relates to a machining process of welding materials, in particular to a machining process of a 5183 aluminum alloy semi-finished welding wire. The machining process comprises the following steps that a wire rod for a raw material aluminum alloy welding wire is fed into a cold rolling mill for rolling through a pay-off rack and a wire rod tensioning mechanism, and the aluminum alloy semi-finished welding wire is obtained; and the welding wire is subjected to annealing treatment after being taken up by a take-up rack, and finally the welding wire is packed and put in storage. Compared with drawing methods, the defects that through drawing processes, lengths are limited, wire breaking and cracking are liable to occur, and pass deformation and total deformation between two timesof annealing are limited can be overcome, the machining process has the advantage of high production efficiency and the advantage of precise control over the welding wire diameter, the cost is moderate, application is convenient, the product quality of the aluminum alloy welding wire is ensured, the product rejection rate is lowered, energy consumption is reduced, the cost is reduced, the labor intensity of staff is relieved, and the potential safety accidents are reduced.

Owner:江苏和拓铝线有限公司

A car uphill assist device

ActiveCN108486981BReduce speedImprove securityTemporary pavingsElectric generatorAutomotive engineering

The invention designs an auxiliary device for vehicle uphill and downhill. The auxiliary device for the vehicle uphill and downhill comprises roller devices, a damping wheel, a position and speed detection device, a solar panel, an electric generator device, a storage battery, a LCD display screen, a controller module. The roller devices, the damping wheel, the position and speed detection device,the solar panel, the electric generator device, the storage battery and the LCD display screen are all connected with the controller module. When a vehicle passes an uphill road, the roller devices provide the forward power for the vehicle by rotating, and the vehicle can be prevented from slipping back. When the vehicle passes through the roller devices, arranged side by side, on a downhill roadsurface, the position and speed information of the vehicle is detected by the position and speed detection device, the controller displays the speed on the LCD display screen; the greater the speed,the greater the damping of the damping wheel on the roller devices; and if the vehicle speed exceeds a certain threshold, the auxiliary device is simple in structure design, is more effective than a general uphill and downhill auxiliary device, and the effect is better.

Owner:温州品力智能幕墙门窗有限公司

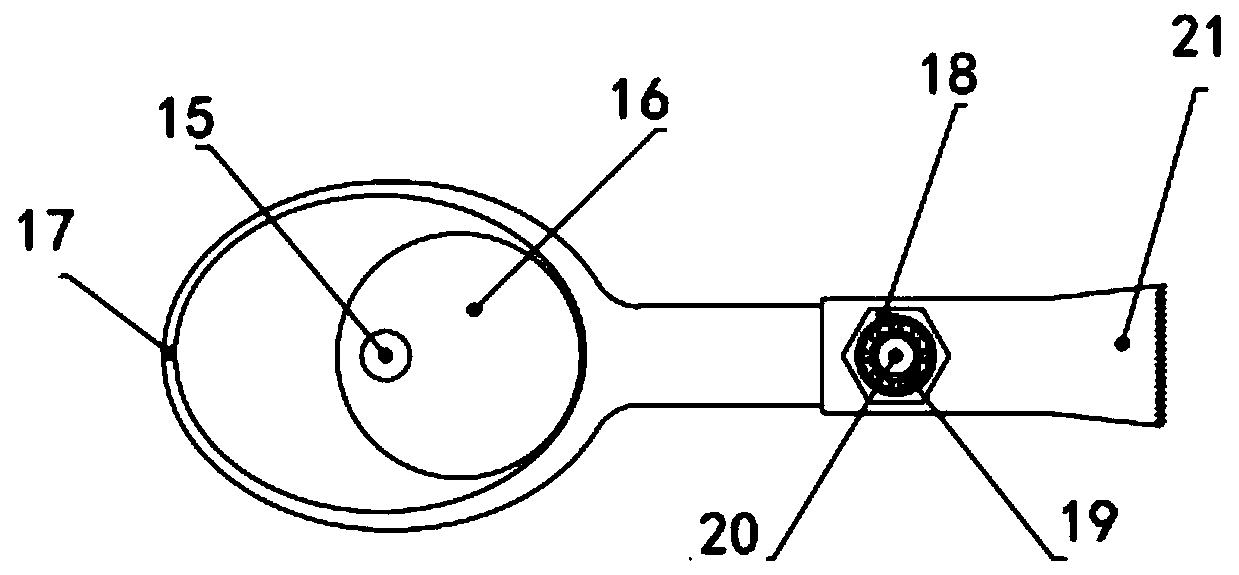

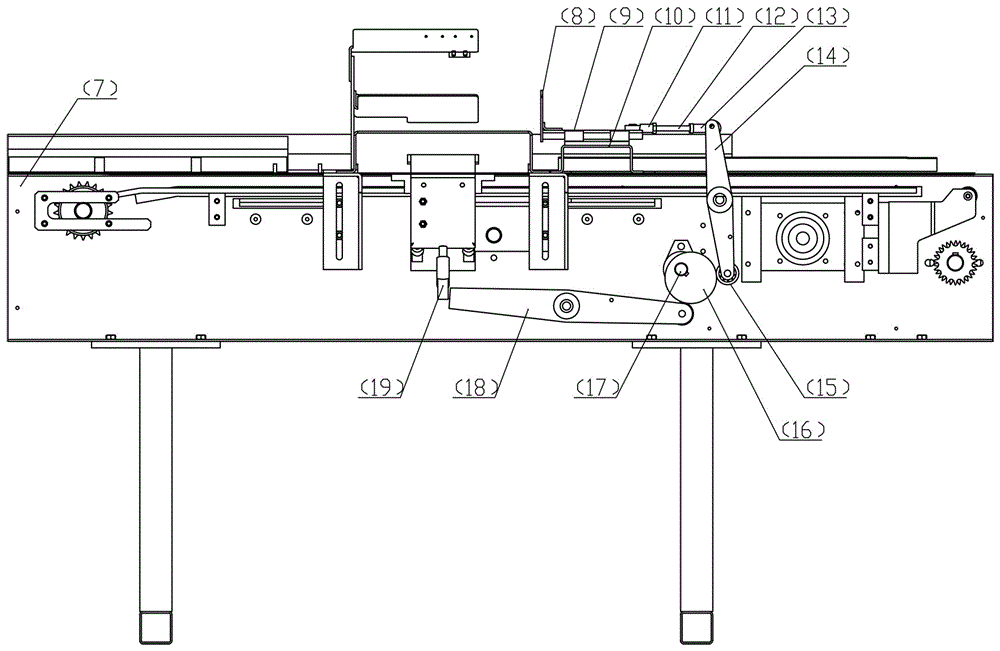

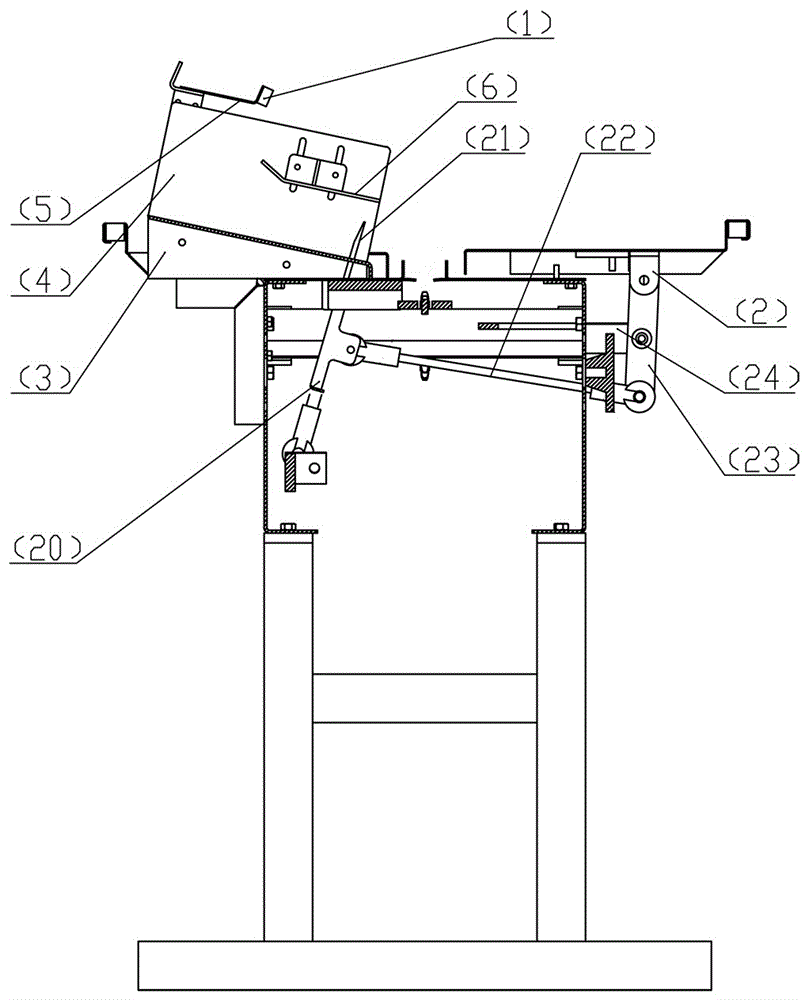

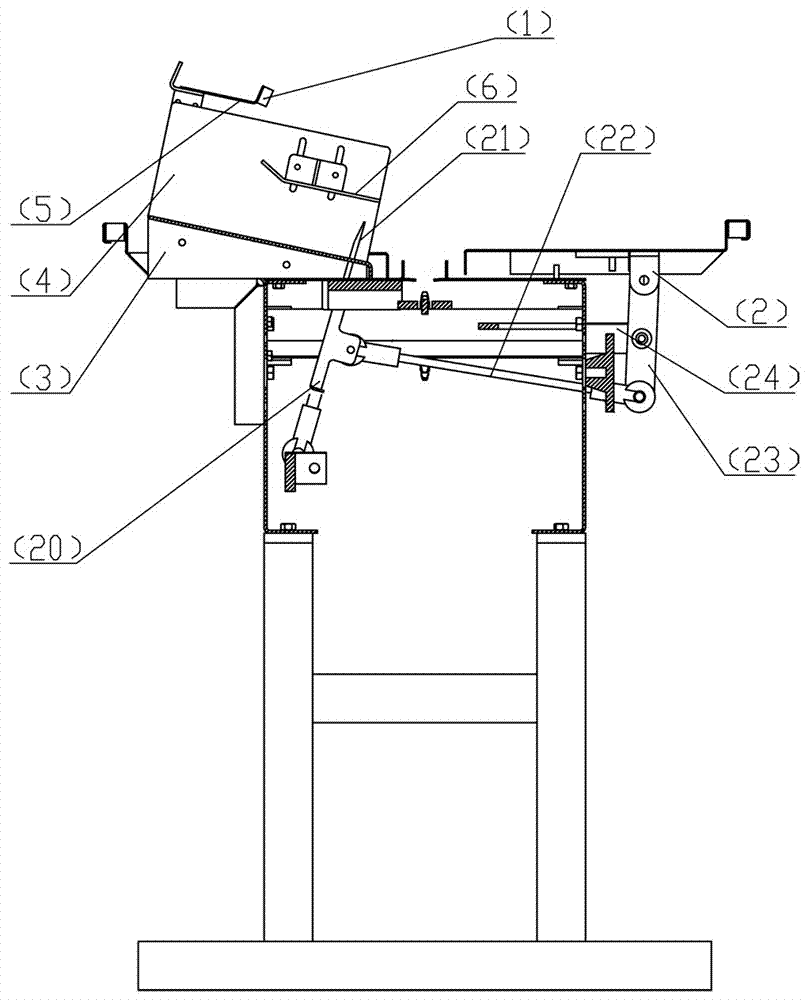

A Cam Eccentric Surface Device

The invention provides a cam eccentric noodle tidying device. The cam eccentric noodle tidying device comprises a noodle conveying mechanism for conveying scattered noodles, a noodle tidying mechanism for tidying the scattered noodles and a noodle placing mechanism. By means of the cam eccentric noodle tidying device, the problems that a scattered noodle machine is poor in tidying effect, high in noise, unstable in function and the like are effectively solved. The cam eccentric noodle tidying device is good in automatic tidying effect, free of noise and stable in function, realizes the universality of existing common equipment, lowers the production cost and improves production efficiency.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

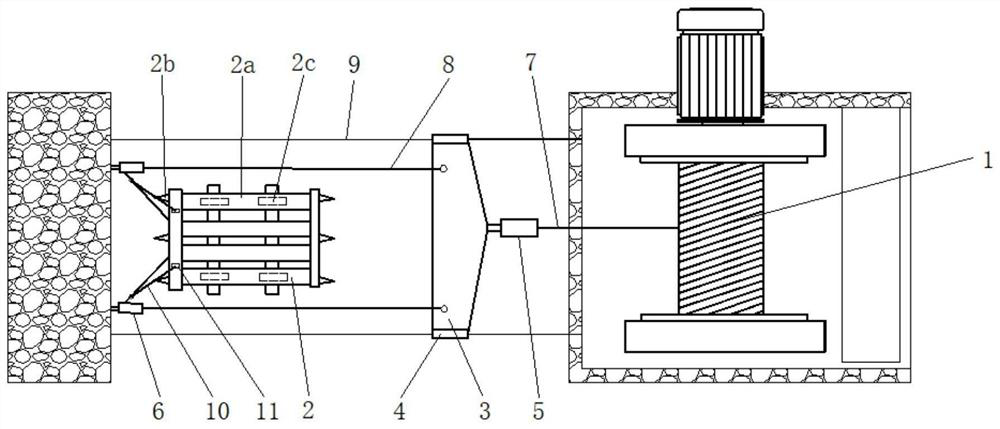

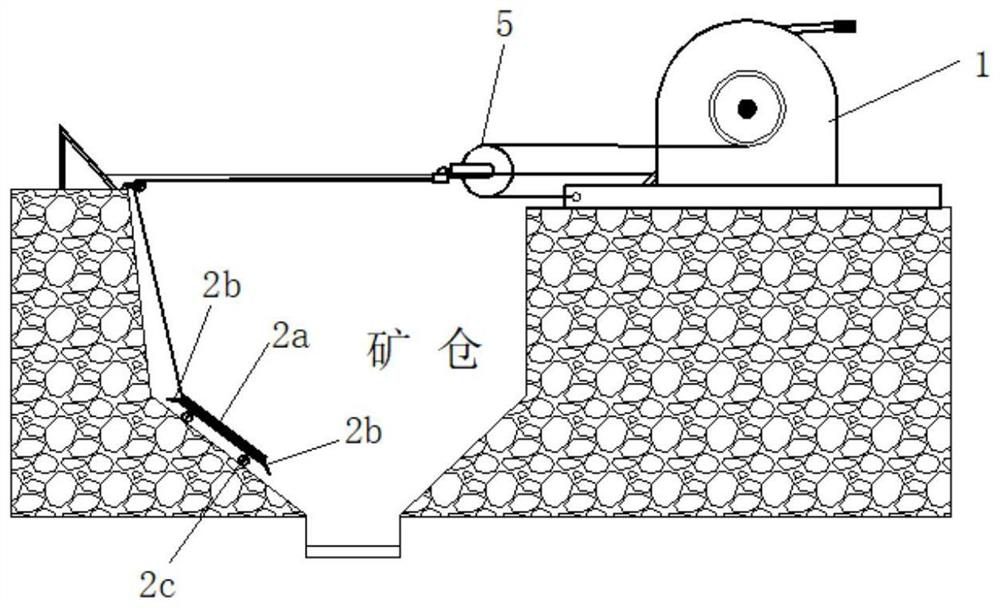

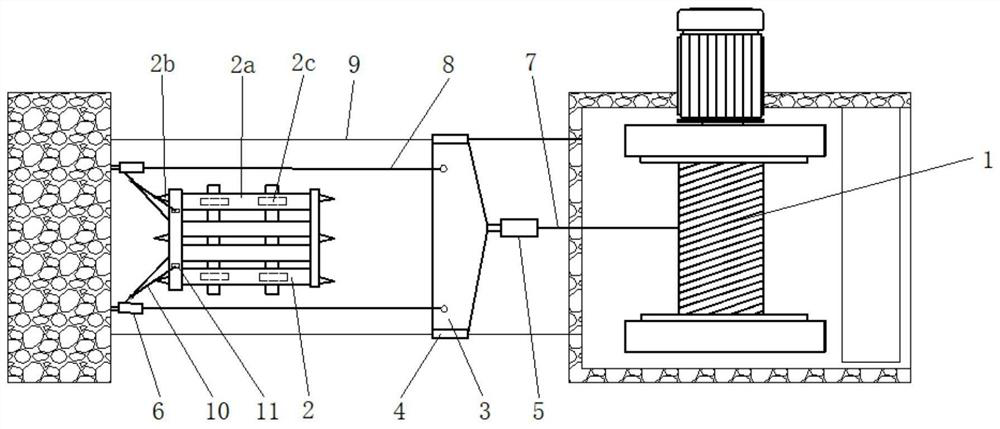

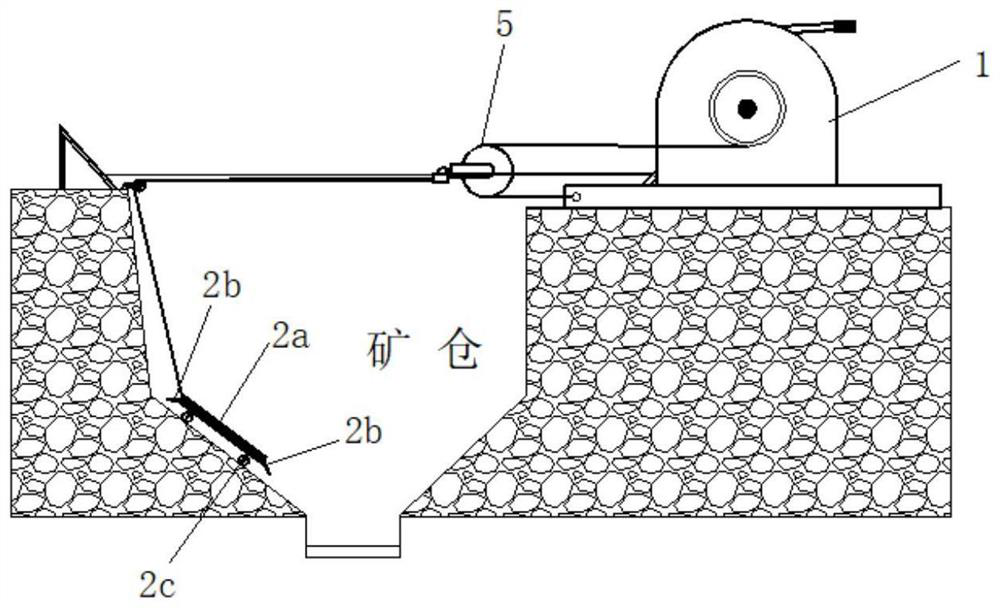

Special mechanical clearing device and clearing method for mine silo

ActiveCN112849790BRapid realization of collapse clearanceAvoid getting in the way of timely collapseLarge containersWinchGuide tube

The invention discloses a special mechanical warehouse clearing device for mine bins. Two guide pulleys are installed on the front side of the top of the mine bin. A guide wire rope is fixed on the left and right sides of the top of the mine bin. Row of rake teeth, the front end of the rake teeth is gradually inclined downward relative to the rear end, the front end of the rake teeth is 2-6cm higher than the bottom of the rake wheel, the lower ends of the two traction wire ropes are fastened to the front end of the rake frame, and the upper end of the traction wire rope is wound around After passing through the corresponding guide pulleys, it is fastened to the front end of the sliding steel plate. The movable pulley is installed at the rear end of the sliding steel plate. The main wire rope of the winch goes around the movable pulley and then folds back for fixed installation. A guide tube is fixedly installed at the left and right ends of the sliding steel plate. , and each guide tube is sheathed on its corresponding guide wire rope. The invention also discloses a silo clearing method using the above-mentioned ore silo special mechanical clearing device. Reduce labor input, reduce production costs, improve production efficiency, and reduce potential safety hazards.

Owner:四川发展天瑞矿业有限公司

A green protection device for a bridge

ActiveCN111576208BChange single formReduce visual fatigueGeneral water supply conservationSelf-acting watering devicesBridge engineeringWater leak

The present invention relates to the technical field of bridge engineering, and discloses a green protection device for bridges, which includes a bottom plate, a top plate located directly above the bottom plate, and a plurality of columns fixed between the bottom plate and the top plate and parallel to each other. There are bases connected between the adjacent columns, and the upper end surface of the base is provided with a sliding groove extending along its length direction, and a number of planting boxes for planting ornamental plants are slidably connected in the sliding groove, and the planting boxes are positioned by fasteners ; The top plate is provided with a water collection chamber for storing rainwater and an irrigation part for spraying the water in the water collection chamber to the planting box. The upper inner wall of the water collection chamber is provided with a water leakage hole for rainwater to flow in; The bottom wall of the sliding groove is provided with a drainage hole extending along its length direction, the drainage pipe is slidably connected in the drainage hole and one end passes through the base. The invention has the effect of effectively reducing the driver's visual fatigue when driving.

Owner:浙江常青公路工程有限公司

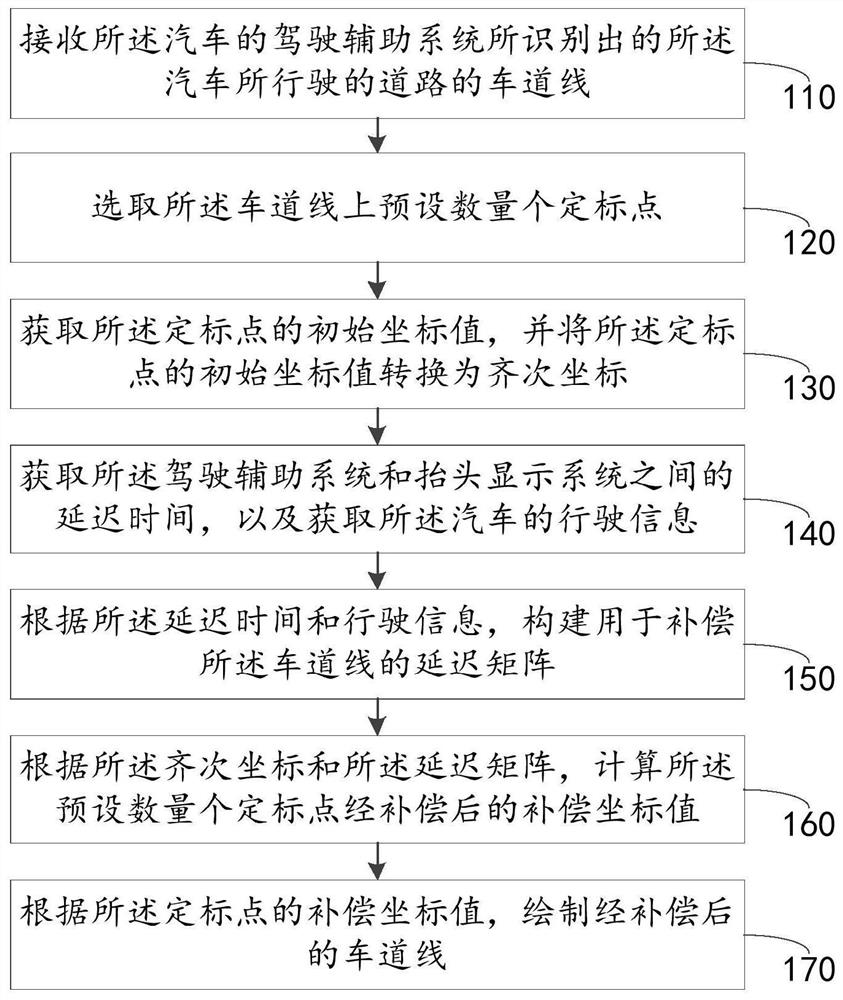

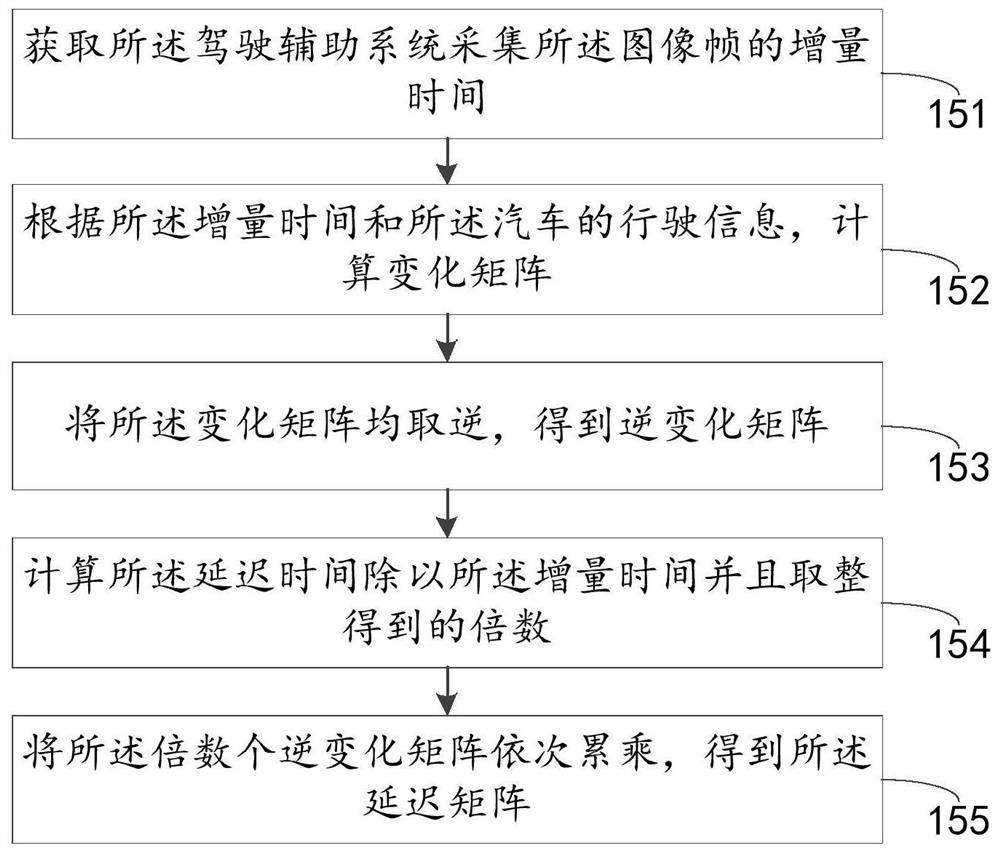

Method, device and server for compensating lane line delay

ActiveCN111086452BReal-time displayReduce the hidden dangers of safety accidentsCharacter and pattern recognitionOptical viewingSimulationReal time display

The embodiment of the present invention relates to the field of automobile technology, and discloses a method for compensating for lane line delay, which is applied to a head-up display system. First, the lane line of the road on which the car is driving is received by the driving assistance system of the car, and the lane line is selected. a preset number of calibration points, and then obtain the initial coordinate values of the calibration points, and convert the initial coordinate values of the calibration points into homogeneous coordinates, and obtain the delay time between the driving assistance system and the head-up display system, and Obtain the driving information of the car, and then construct a delay matrix for compensating lane lines according to the delay time and driving information, so as to calculate the compensated coordinate values of a preset number of calibration points after compensation based on the homogeneous coordinates and the delay matrix, and finally According to the compensation coordinate value of the calibration point, the compensated lane line is drawn, and the method provided by the embodiment of the present invention can display the lane line in real time, reducing the hidden danger of safety accidents.

Owner:合肥疆程技术有限公司

Bendable air gun

InactiveCN112743050AImprove efficiency and qualityAvoid working at the same timeMoulding toolsCleaning using gasesPhysicsEngineering

The invention relates to a bendable air gun. The bendable air gun comprises a handle, a bendable gun nozzle, an LED lamp, a display screen, a micro camera and a switch button. The handle is mounted at one end of the bendable gun nozzle. The micro camera is mounted on the outer wall of the other end of the bendable gun nozzle. The LED lamp is mounted at the lower part of the micro camera. The display screen is mounted at the upper parts of the handle and the bendable gun nozzle. The switch button is installed on the side face of the handle. The bendable gun nozzle is made of a high-ductility alloy. The bendable gun nozzle has good stability when the air pressure does not exceed 0.6 Mpa. The bending angle of the bendable gun nozzle is 0-150 degrees. The bendable air gun is provided and overcomes the defect that in the prior art, when an air gun cleans a sand core with a cavity, cleaning cannot be conducted or cannot be conducted thoroughly. According to the device, the sand cleaning efficiency and quality are improved, meanwhile, the situation that two hands of a worker work at the same time is avoided, potential safety hazards are reduced, and the safety of the worker is guaranteed.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

A line safety patrol device and using method thereof

ActiveCN111071442BReduce crossingReduce the hidden dangers of safety accidentsRemote controlled aircraftCable installation apparatusWireless transmissionRemote control

Owner:STATE GRID JIBEI ELECTRIC POWER CO LTD TANGSHAN POWER SUPPLY CO +1

Special mechanical bin cleaning device for ore bin and bin cleaning method

ActiveCN112849790ARapid realization of collapse clearanceAvoid getting in the way of timely collapseLarge containersMining engineeringWinch

The invention discloses a special mechanical bin cleaning device for an ore bin and a bin cleaning method. Two guide pulleys are mounted at the front side of the top of the ore bin, the left side and the right side of the top of the ore bin are each fixedly provided with a guide steel wire rope, a row of rake teeth are arranged at the left side and the right side of the front end of a rake frame at intervals, and the front ends of the rake teeth are gradually inclined downwards relative to the rear ends; the front ends of the harrow teeth are 2-6 cm higher than the bottom of a harrow wheel, the lower ends of the two traction steel wire ropes are fastened to the front end of the harrow frame, the upper ends of the traction steel wire ropes wind around the corresponding guide pulleys and then are fastened to the front end of a slide steel plate, a movable pulley is mounted at the rear end of the sliding steel plate, and a main steel wire rope of the winch winds around the movable pulley and then is folded back to be fixedly mounted; the left end and the right end of the sliding steel plate are each fixedly provided with a guide tube, and each guide tube is arranged on the corresponding guide steel wire rope in a penetrating and sleeving mode. The invention further discloses an ore storage bin cleaning method using the special mechanical bin cleaning device for the ore bin. The special mechanical bin cleaning device reduces labor investment, reduces production cost, improves production efficiency and reduces potential safety hazards.

Owner:四川发展天瑞矿业有限公司

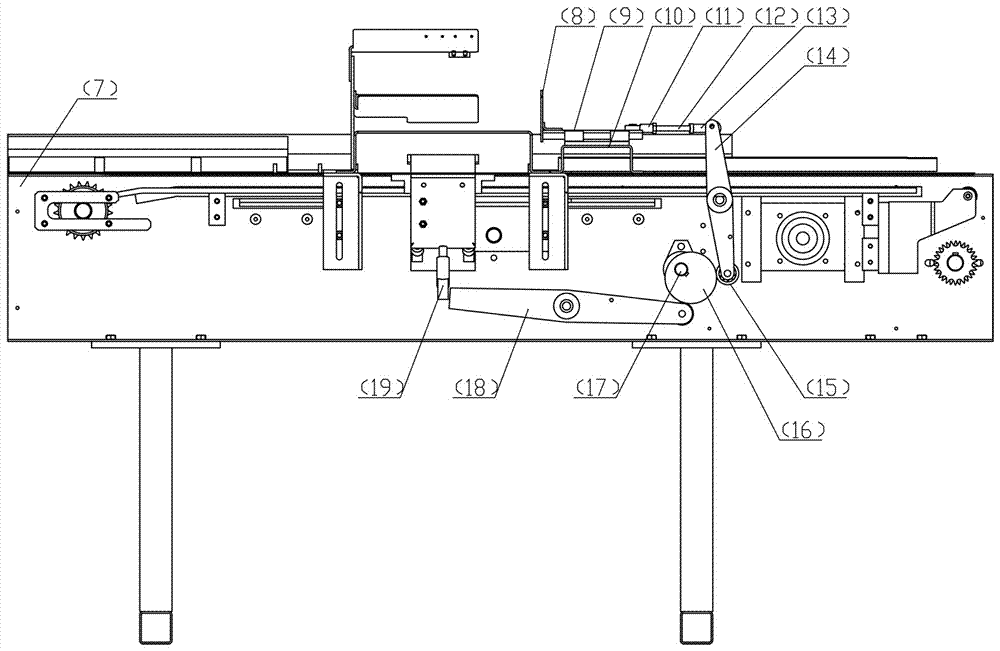

Cam type feed device for circularly-packaged fine dried noodles

The invention provides a cam type feed device for circularly-packaged fine dried noodles. The device can effectively solve the problems that the circularly-packaged fine dried noodles cannot be mechanically and automatically arranged and manual management is high in empty bag rate, large in labor intensity and low in efficiency. The device has the functions of automatic management and material conveying, and can automatically arrange and convey the circularly-packaged fine dried noodles. Universality of conventional devices is achieved, the production cost is reduced, the production efficiency is improved, stable and rapid arrangement of the circularly-packaged fine dried noodles can be achieved, and the cam type feed device can be commonly used for circular packaged object management.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

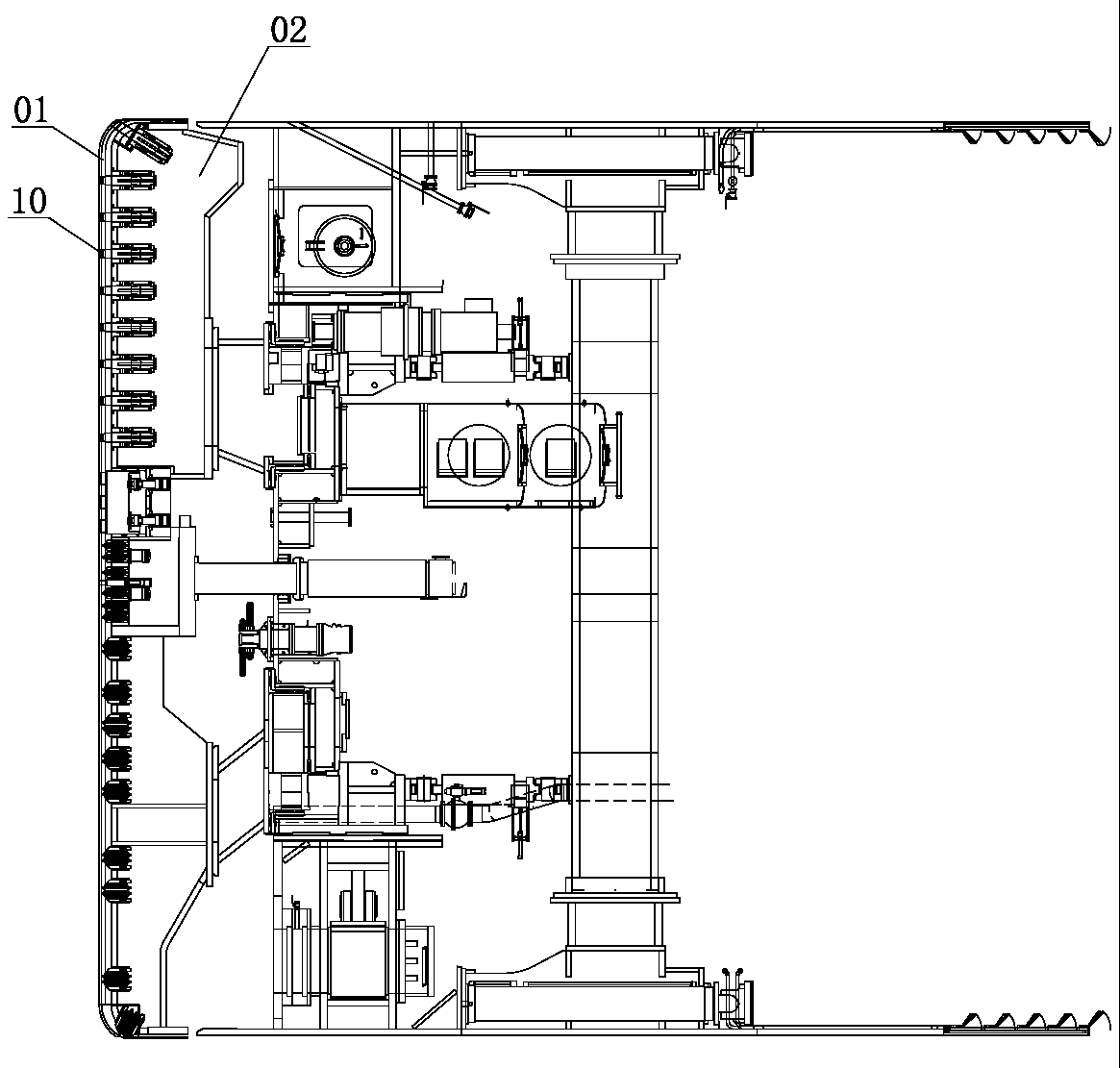

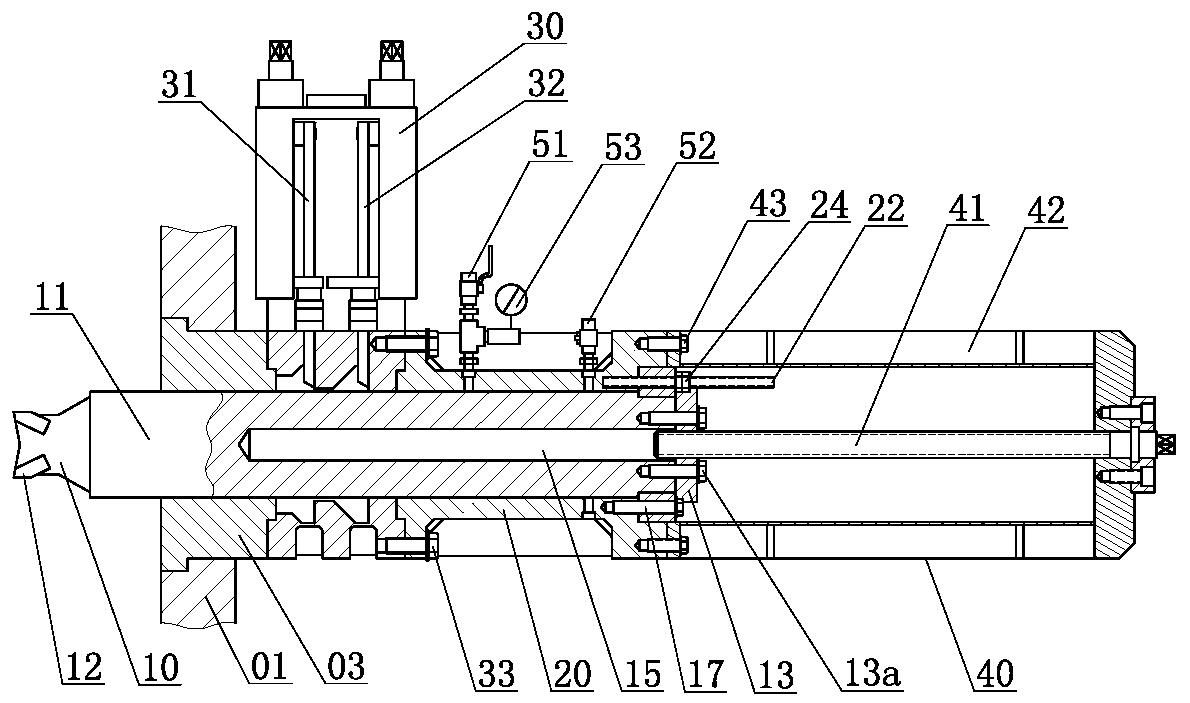

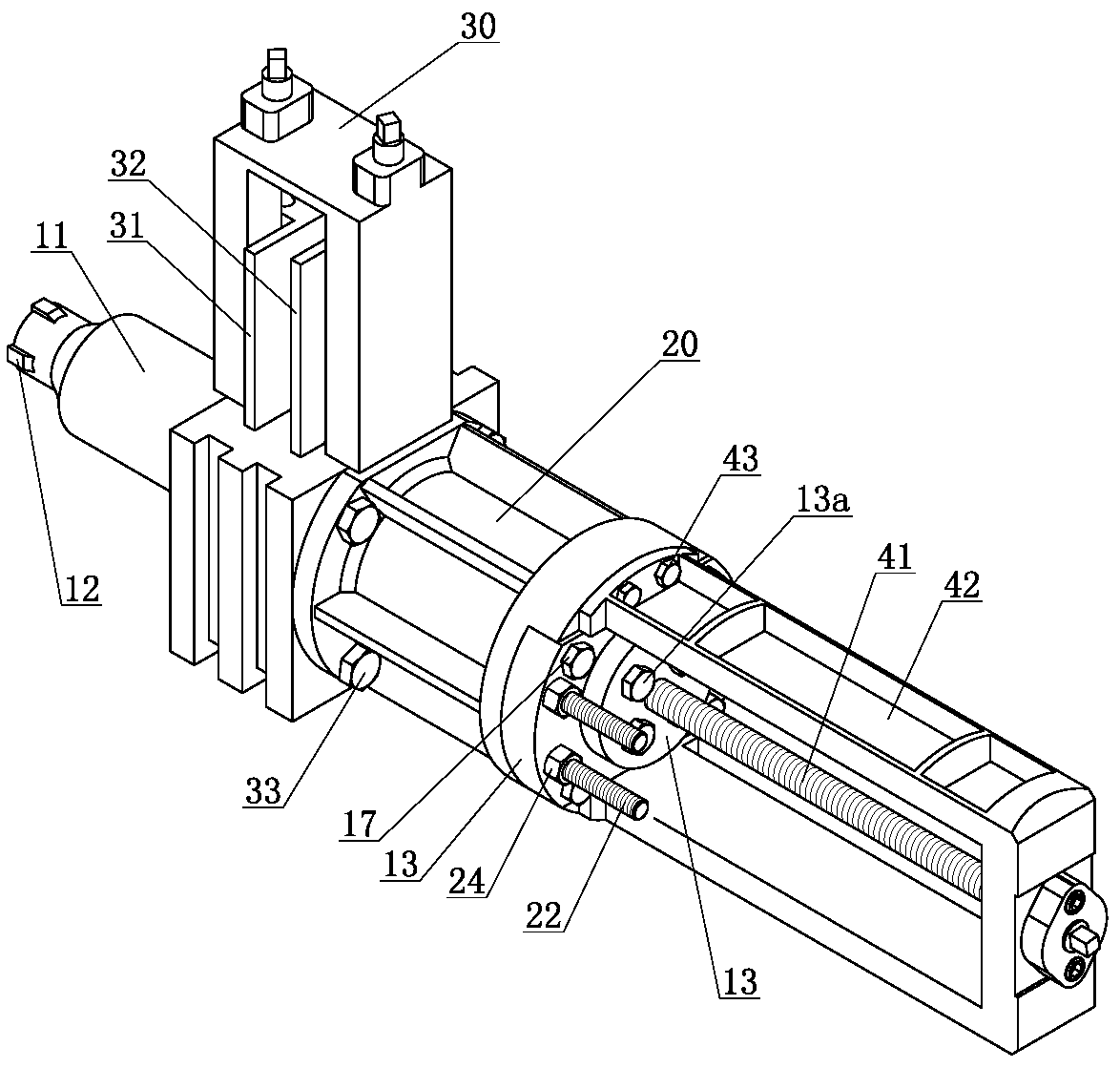

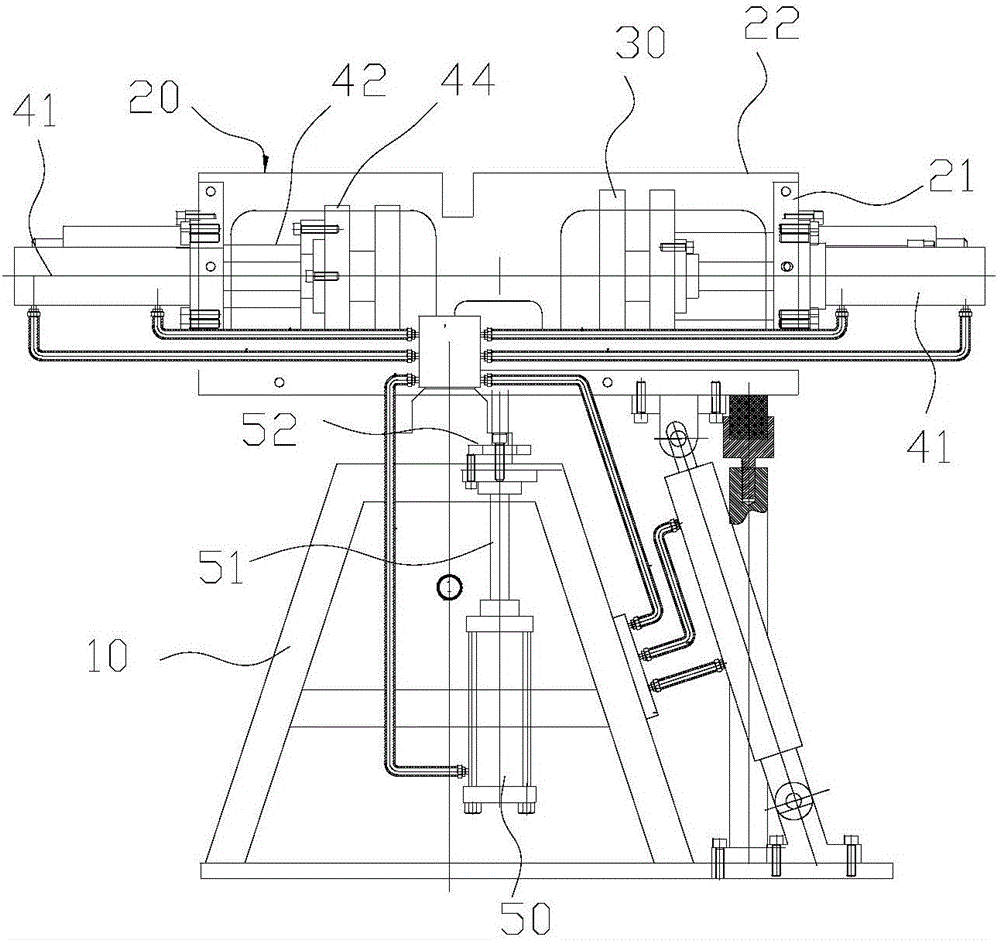

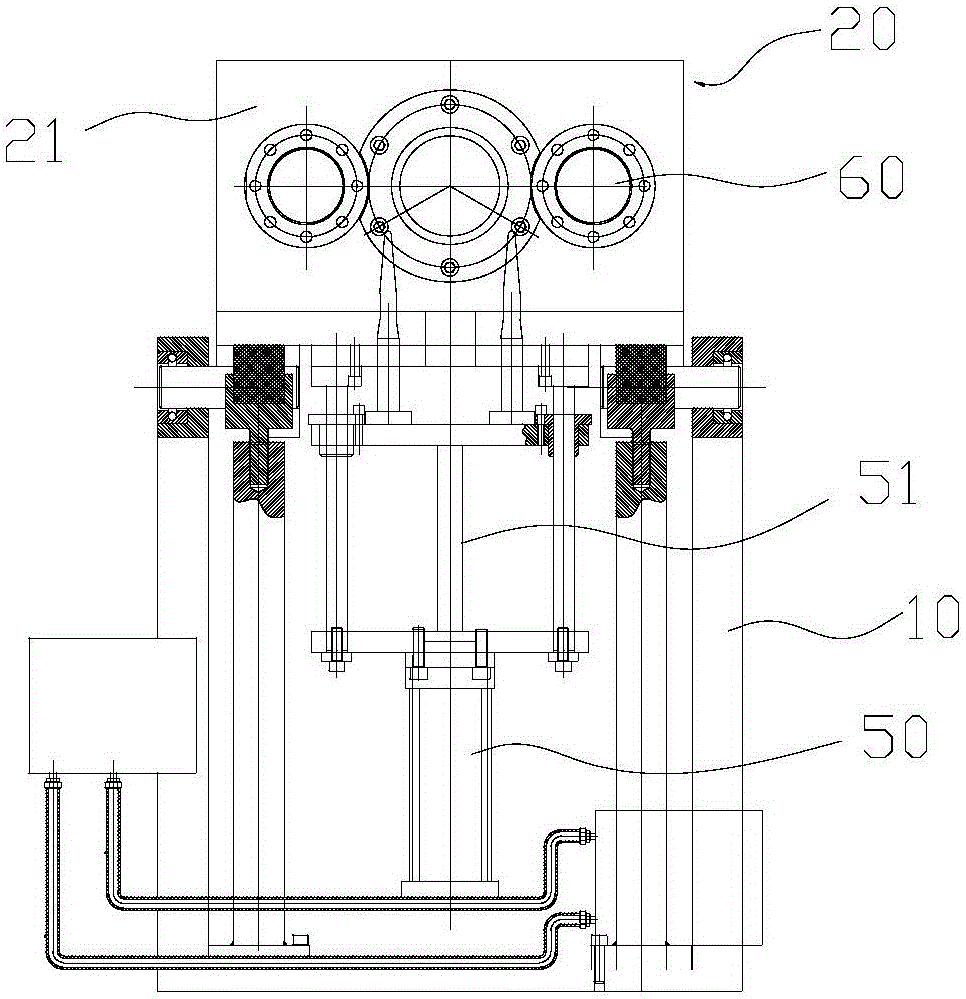

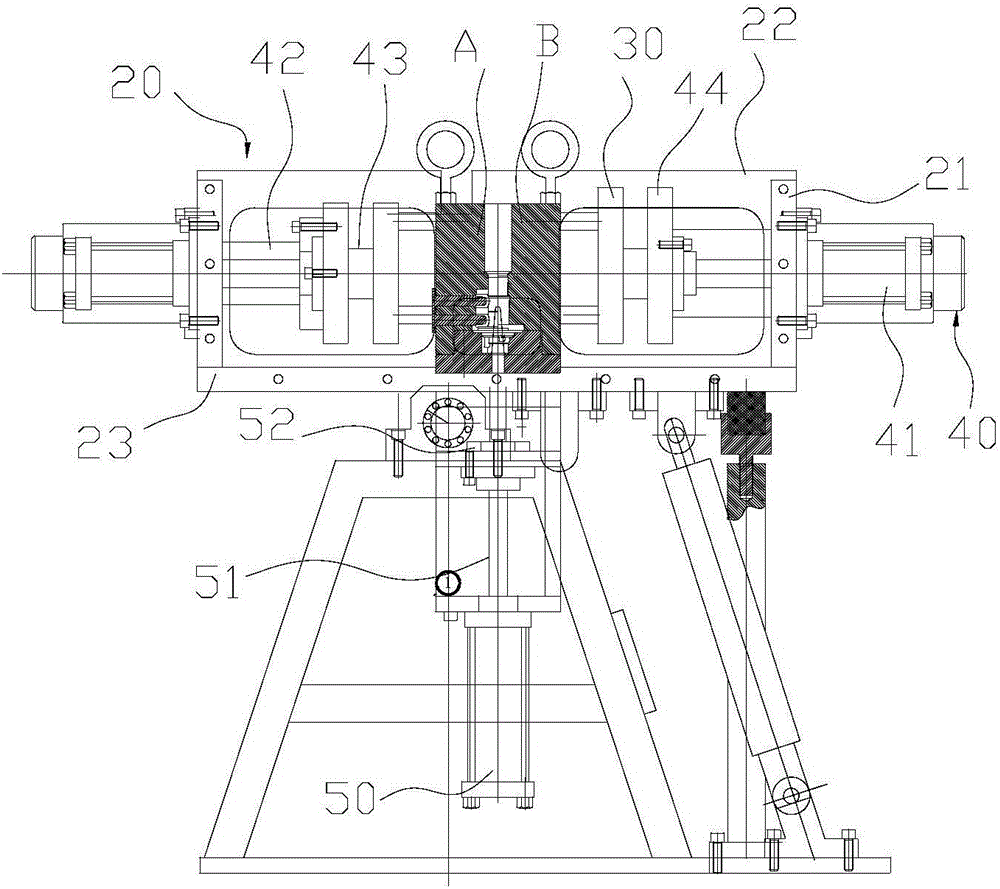

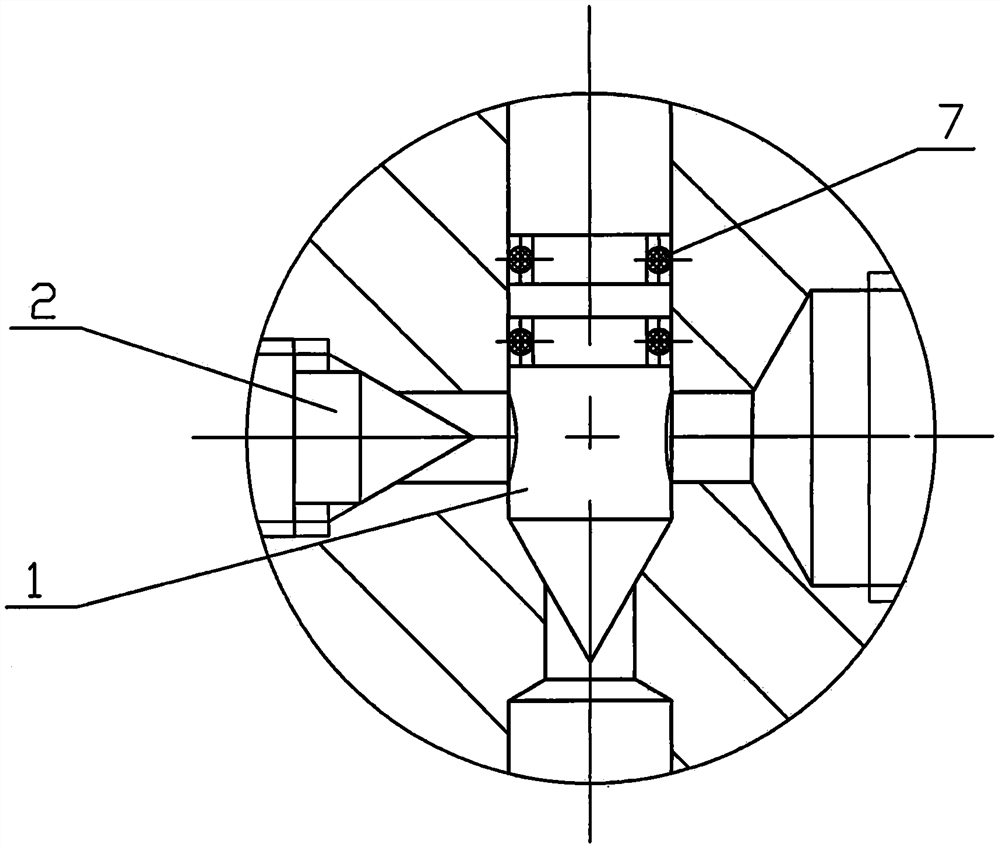

An atmospheric pressure tool changing device and method for a super-large-diameter shield machine

The invention relates to an ordinary-pressure tool-changing device and method of an extra-large-diameter shield tunneling machine. Multiple cutting tools are installed in a spoke working cabin of a shield tunneling machine cutter disc. The spoke working cabin is an ordinary-pressure working cabin, a cutter box is arranged on the cutter disc, and each cutting tool is installed on the cutter box. A sealing valve 30 is arranged between the cutter disc and the cutter box, a cutting tool installation clamp is arranged at the rear end of the cutter box and is provided with a clamp lead screw for release and installation of the cutting tools. The cutting tools are changed in the working cabin in a common usage state. The ordinary-pressure tool-changing device has the advantages that each spoke is internally provided with an independent airtight working cabin by reasonably optimizing a cutter disc structure, an operator can enter the airtight cabin for checking and replacement of the cutting tools on a cutter disc panel under the ordinary-pressure condition, the risk that the operator enters an excavation cabin for operation under the ordinary-pressure or under-pressure condition is avoided, the hidden dangers of safety accidents are decreased, the device maintenance cost can be remarkably reduced, and the ordinary-pressure tool-changing device has a remarkable application effect.

Owner:CCCC TUNNEL ENG

Steel die splitting and assembling device for pouring

InactiveCN105880472AReduce labor intensityAvoid lostFoundry mouldsFoundry coresHeat lossesEngineering

The invention aims to provide a steel die splitting and assembling device capable of automatically implementing die assembling and splitting actions. According to the steel die splitting and assembling device, a base is provided with a rack; the rack is provided with die connecting plates connected with split units constituting a die; the die connecting plates are connected with a movable clamping mechanism, and the movable clamping mechanism drives the die connecting plates to implement die assembling or die splitting action together with the split units of the die; and a heat insulation unit is arranged between the die connecting plates and the movable clamping mechanism, so that heat loss of the die is avoided, and temperature distortion of moving components like the movable clamping mechanism is also avoided. Die assembling accuracy of the split units of the die is improved, the influence of external force interference is avoided during die splitting, and thus smooth implementation of the die splitting action is guaranteed.

Owner:安徽东立汽车部件有限公司

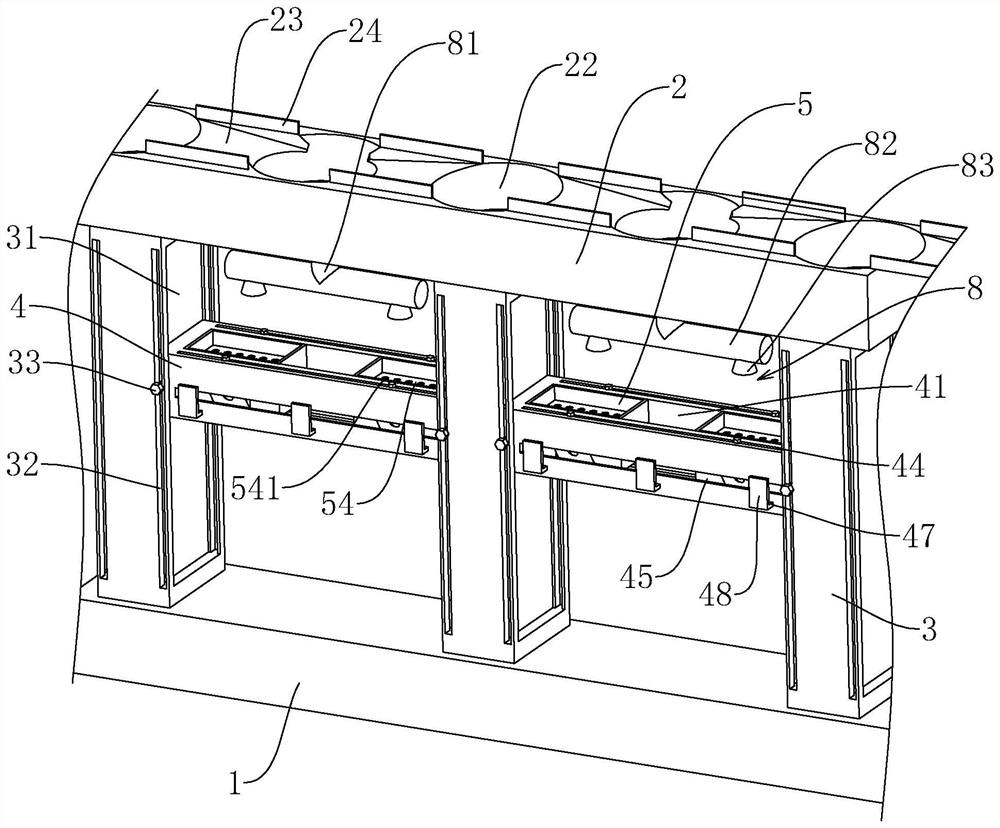

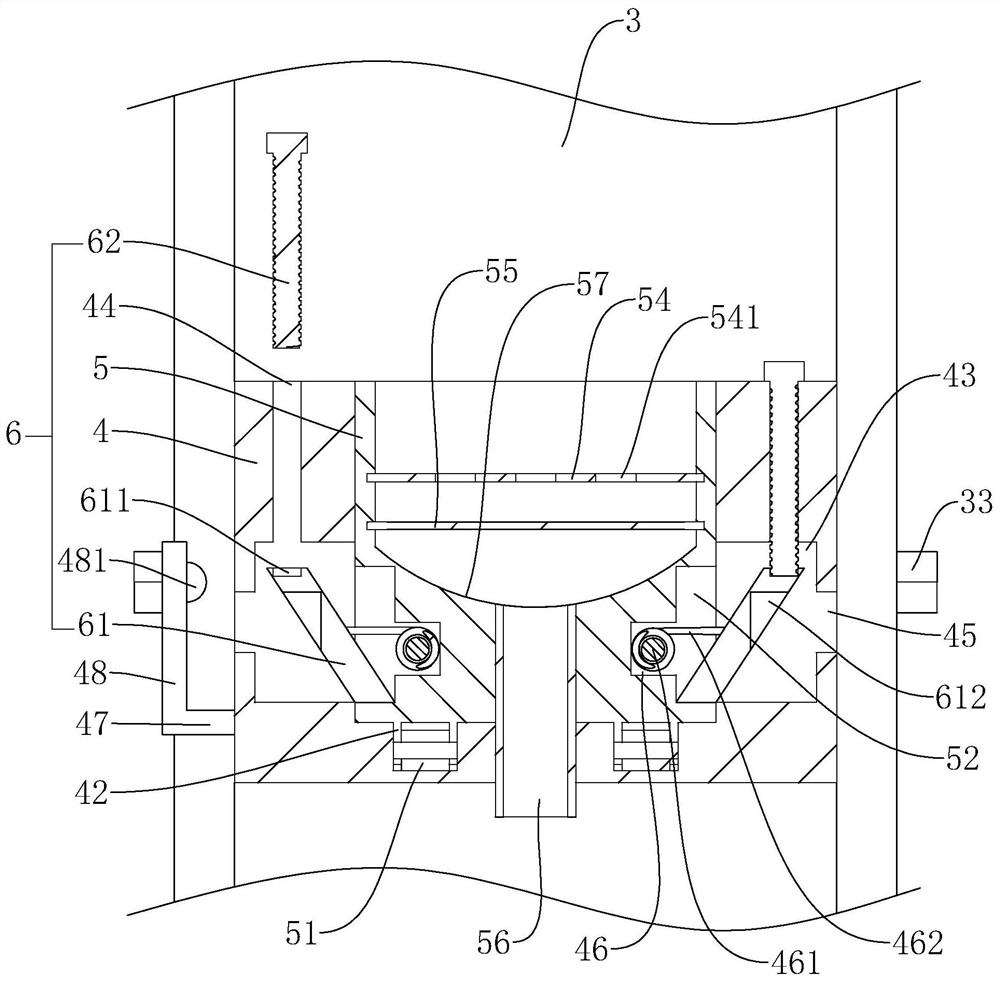

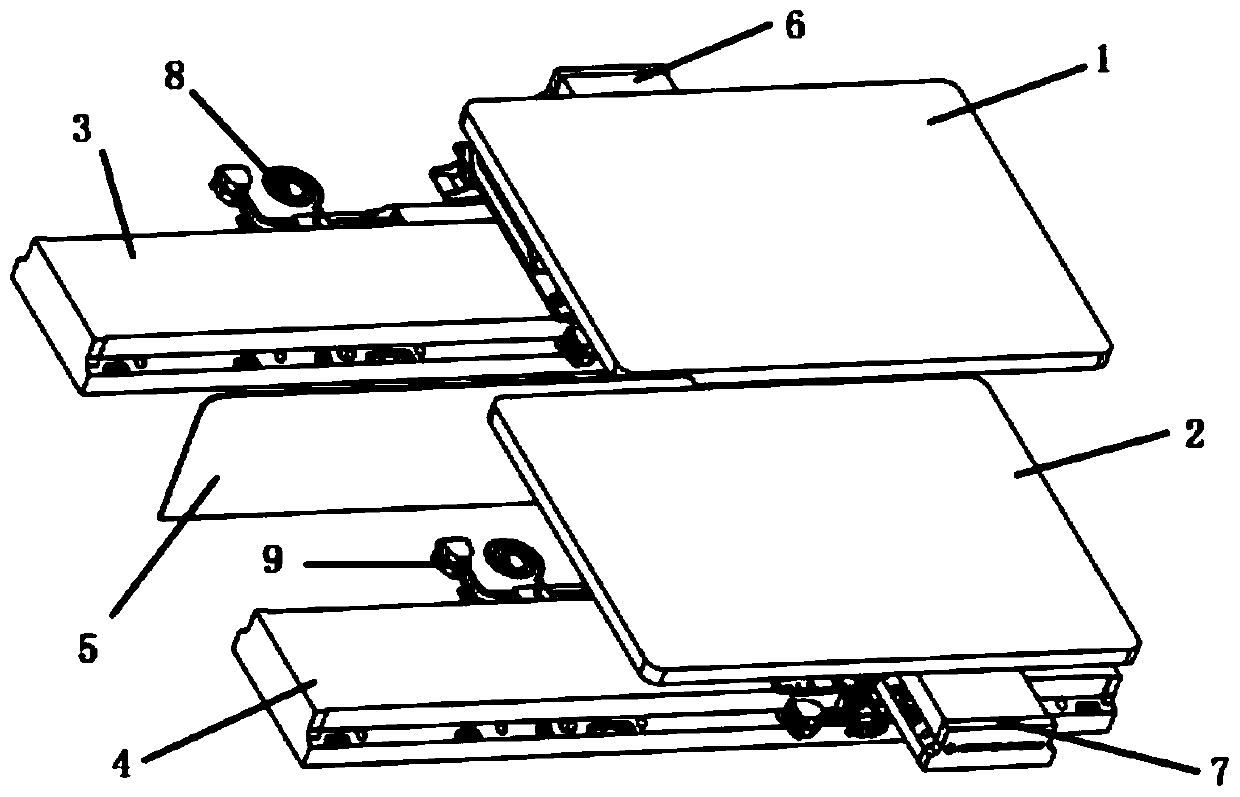

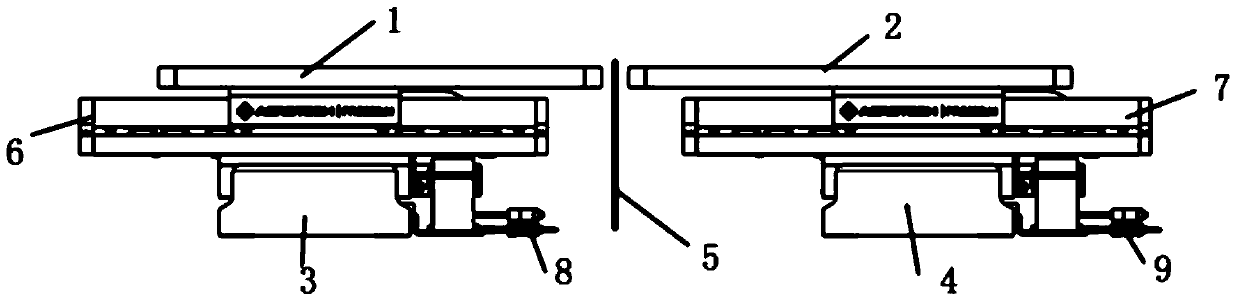

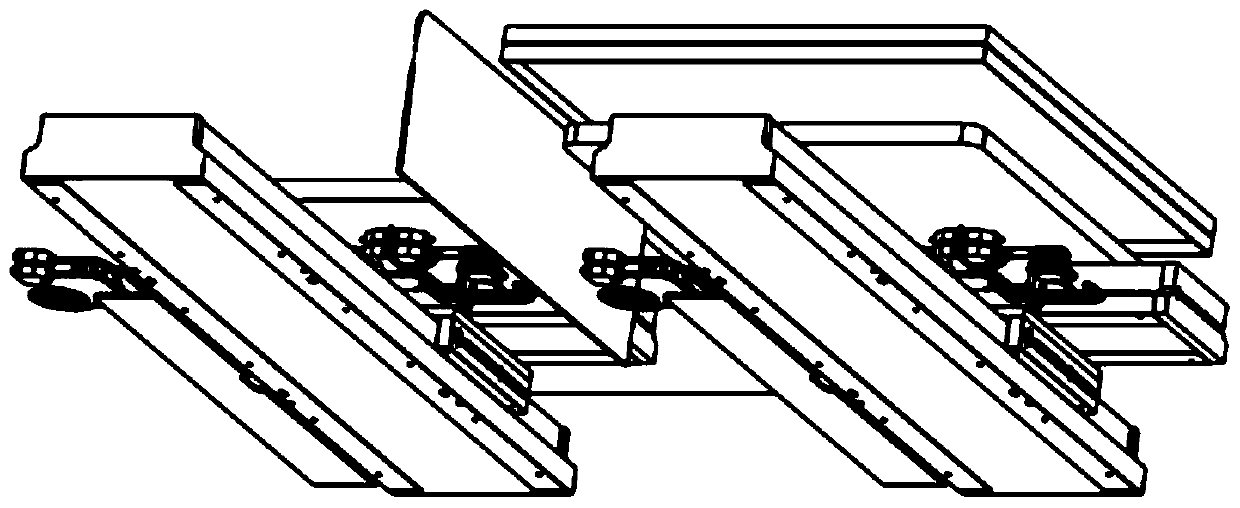

A kind of ldi double workpiece exposure device and exposure method

ActiveCN104950599BAvoid contact injuryReduce the hidden dangers of safety accidentsPhotomechanical exposure apparatusMicrolithography exposure apparatusMechanical engineeringMotion range

Owner:中夏芯基(上海)科技有限公司

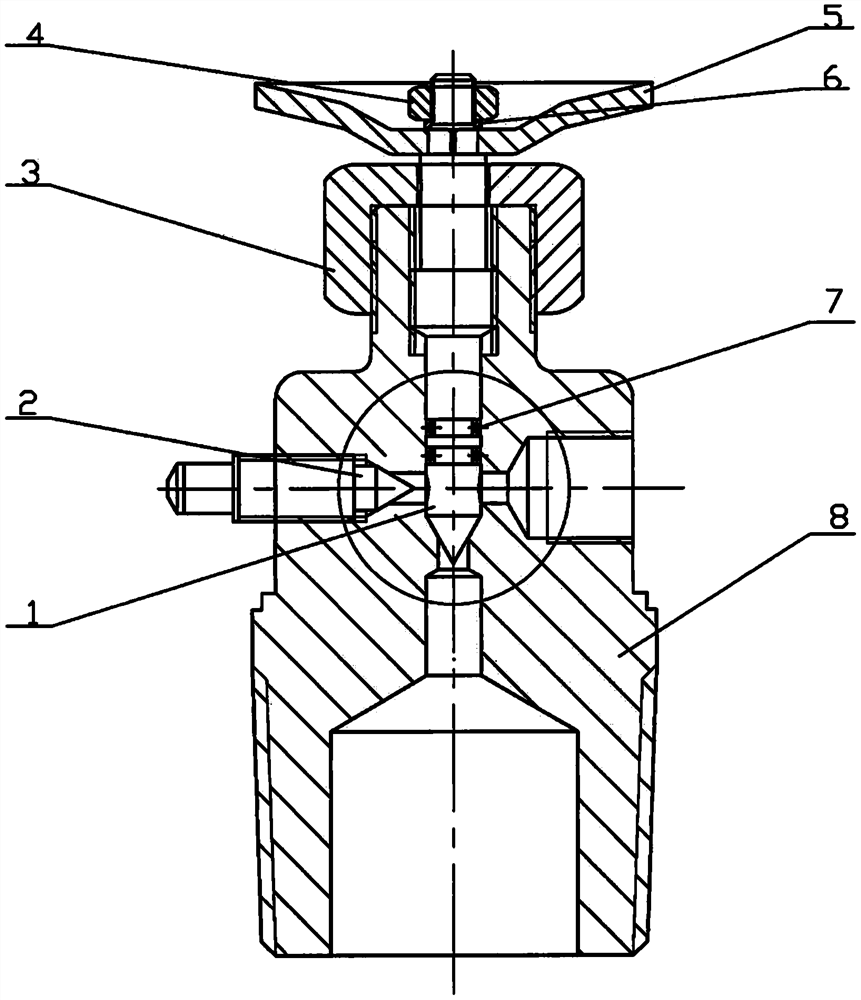

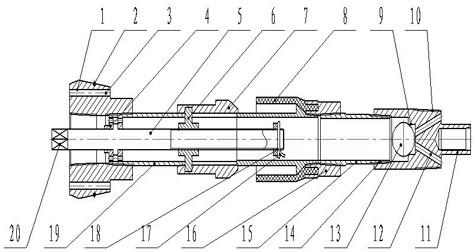

Adapter capable of controlling pressure

PendingCN113389921ARealize the mergerReduce labor intensityOperating means/releasing devices for valvesMultiple way valvesPhysicsEngineering

The invention relates to an adapter capable of controlling pressure. A valve needle 1 is in threaded connection with an adapter body, and two annular grooves are formed in the valve needle 1 and used for containing O-shaped sealing rings to enhance the sealing performance of the adapter. One end of the adapter body is processed into a taper external thread, and an external thread at the other end and a shell cap internal thread are the same in model. A shell cap is screwed on the adapter body to prevent the valve needle 1 from leaving the adapter body, a hand wheel is placed on the valve needle 1, a nut screws the valve needle 1 to fix the hand wheel, and a gasket is placed between the hand wheel and the nut. Two opposite internal threads are designed on the same horizontal line of the adapter body and are used for containing a valve needle 2 and connecting a pressure gauge. The device has the advantages that a stop valve is machined on the adapter body, so that the adapter and the stop valve are combined, the production cost is saved, and the labor intensity of operators is relieved; and then the valve needle 1 and the valve needle 2 are opened or closed, so that the working state of the pressure gauge is controlled, and when the pressure gauge is replaced, the potential safety hazard is reduced, and the working efficiency and the economic benefit are improved.

Owner:盐城金龙达机械制造有限公司

Smoke dust treatment method

PendingCN112206619AAvoid dangerReduce the hidden dangers of safety accidentsCombination devicesSmokeWaste gas

The invention discloses a smoke dust treatment method. The smoke dust treatment method comprises the following specific steps that (1) smoke dust runs along a preset channel in a negative pressure airdraft mode; (2) high-pressure spraying is performedthrough a spraying head to enable the smoke dust and water to be mixed for the first time; (3) the smoke dust continues to pass through a water-vapor mixing device to realize gas-liquid mixing; (4) the water vapor is mixed again through secondary high-pressure spraying of the spraying head; (5) the smoke dust continues to run along the preset channel, and part of large particles settle under the action of gravity; (6) steam and water in the smoke dust are separated in a physical water removal mode; (7) steam and water in the smoke dust are separated in a power water removal mode; and (8)a dust removal deviceis used for removing dust from the residual gas after two times of water removal and separation. The method has the beneficial effects that the safety accident hidden danger is reduced by combining dry and wet filtering; waste gas is directionally separated through multi-stage filtering, and certain economic benefits are achieved;99% of water vapor in the smoke dust is removed by combining physical water removal and dynamic water removal, the service life of the filter cartridge is prolonged, the cost is saved, meanwhile, theeffectiveness of high-standard purification is guaranteed, and the emission concentration after equipment treatment can reach 10 mg / m < 3 > (actual measurement), and the filtering efficiency exceeds 99.5%.

Owner:山东两棵松环保科技有限公司

Pressure testing device and pressure testing method for rod pump wellhead facilities

ActiveCN110056325BFlexible arrangementConvenient ArrangementSurveySealing/packingStructural engineeringOil production

The present invention relates to a pressure test device and a pressure test method for the wellhead facilities of rod pump oil production wells, which can realize the wellhead facilities under low displacement during the process of pulling up the sucker rod, such as: wellhead cross, well sealing device, The wellhead pressure test of blowout pipeline and other components and devices can improve the working efficiency and reduce the labor intensity of employees. The pressure test device includes a pressure test sealing mechanism and a pipe rod connector. The pressure test sealing mechanism and the pipe rod connector are connected through a variable diameter joint. The sucker rod is connected to the oil pipe; the pressure test sealing mechanism is equipped with a cup and a tubing hanger, and a tightening cone and a force application pipe are installed between the tubing hanger and the cup, and the tension cone can move along the force application pipe 1. Expand the leather cup to seal the inner cavity of the downhole casing. It overcomes the problem that the existing technology cannot perform pressure test on the wellhead facilities in the process of lifting the sucker rod, effectively improves the operation timeliness, and reduces the hidden dangers of well control safety accidents.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Dilemma Control Method for Signalized Intersections Based on Real-time Vehicle Trajectories

ActiveCN104282161BReduce the numberReduce the hidden dangers of safety accidentsControlling traffic signalsPhase controlGreen-light

The invention relates to a signalized intersection dilemma region control method based on a real-time vehicle track. The method is characterized by including the following steps that (1) state information of vehicles about to pass an intersection is acquired through a holographic detection device of the intersection; (2) according to the acquired state information of the vehicles about to pass the intersection, signal phase control of the intersection is conducted, and whether green light time needs to be prolonged or not is determined according to the acquired number of the vehicles located in a first dilemma region and a second dilemma region at the current moment and prediction of the number of the vehicles located in the first dilemma region and the second dilemma region at the next moment. Compared with the prior art, the method has the advantages of being high in safety, easy to implement, advanced and the like.

Owner:TONGJI UNIV

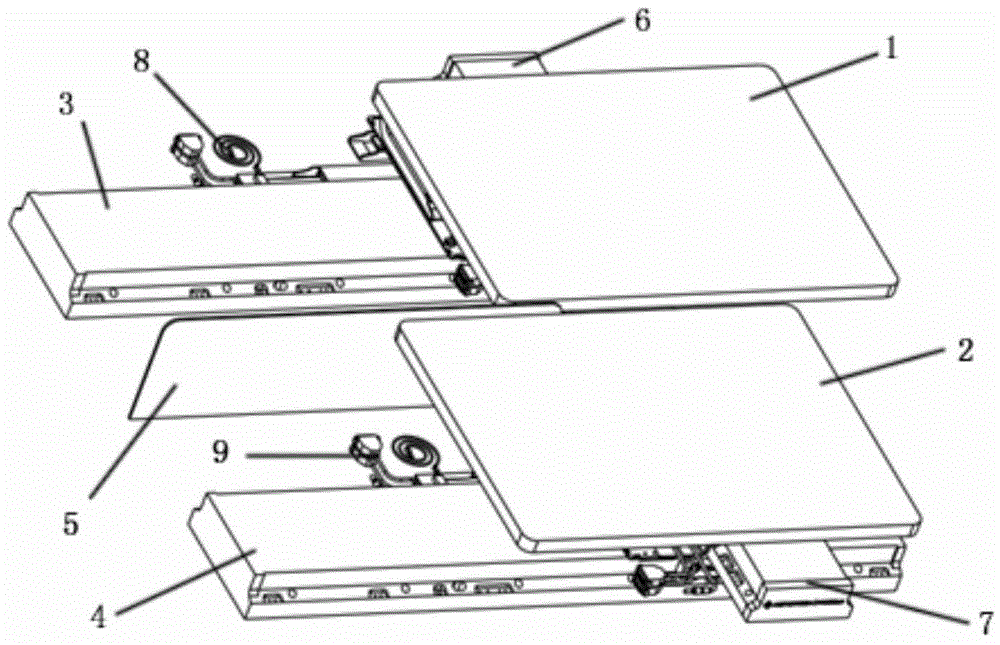

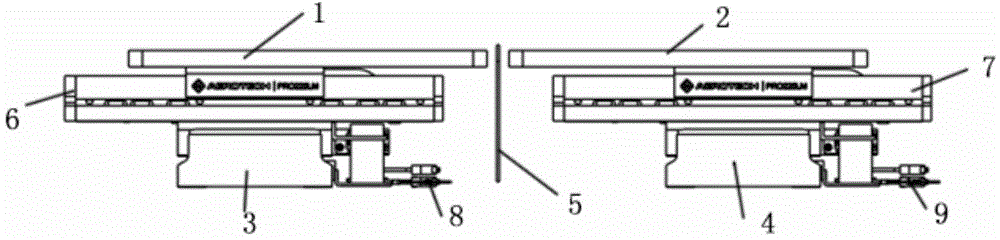

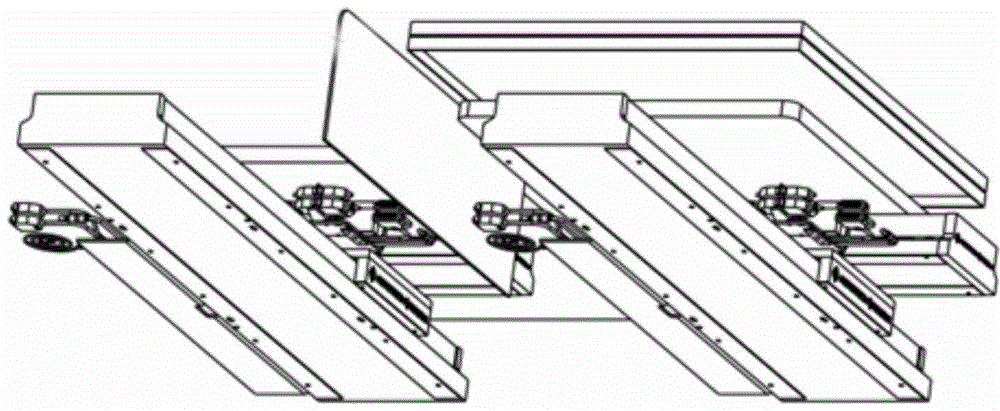

LDI double workpiece exposure device and exposure method

ActiveCN104950599AAvoid contact injuryReduce the hidden dangers of safety accidentsPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

The invention provides an LDI double workpiece exposure device. The exposure device comprises a first protective door, a second protective door, a first workpiece table and a second workpiece table, wherein the first workpiece table and the second workpiece table are respectively used for fixing a to-be-exposed PCB panel, and the PCB panel is exposed by the first workpiece table and the second workpiece table within the self shift motion ranges; the first protective door and the second protective door are respectively arranged on the upper sides of the first workpiece table and the second workpiece table, are parallel with each other and positioned on different planes, and can be respectively moved to the upper sides of the first workpiece table and the second workpiece table along respective planes. The invention also provides an exposure method for the LDI double workpiece exposure device. According to the exposure device provided by the invention, safety doors are arranged, so that operating personnel can be prevented from touching the running workpiece tables; the workpiece tables are separated by protective baffles, so that the hands of operating personnel can be prevented from mistakenly entering one side of an exposure zone and being knocked by a running sucker.

Owner:中夏芯基(上海)科技有限公司

A cam type feeding device for round packaged dried noodles

The invention provides a cam type feed device for circularly-packaged fine dried noodles. The device can effectively solve the problems that the circularly-packaged fine dried noodles cannot be mechanically and automatically arranged and manual management is high in empty bag rate, large in labor intensity and low in efficiency. The device has the functions of automatic management and material conveying, and can automatically arrange and convey the circularly-packaged fine dried noodles. Universality of conventional devices is achieved, the production cost is reduced, the production efficiency is improved, stable and rapid arrangement of the circularly-packaged fine dried noodles can be achieved, and the cam type feed device can be commonly used for circular packaged object management.

Owner:QINGDAO HAIKEJIA ELECTRONCE EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com