Monitoring method for safety belt status

A condition monitoring system and seat belt technology, applied in the directions of seat belts, measuring devices, surveying and navigation, etc., can solve the problems of complex environment, not in the same construction site, and omissions in the wearing and use of seat belts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

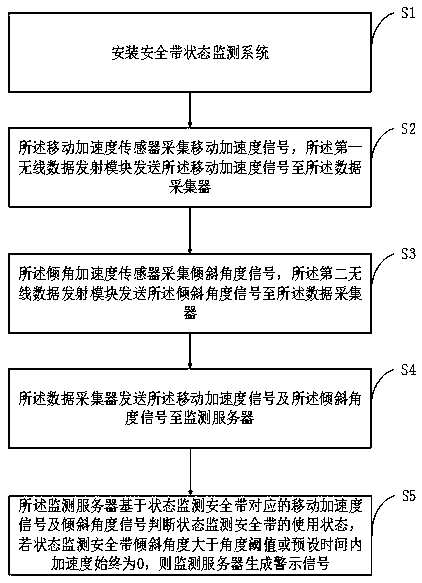

[0040] Such asfigure 1 As shown, the present invention discloses a safety belt state monitoring method, and the safety belt state monitoring method includes the following steps:

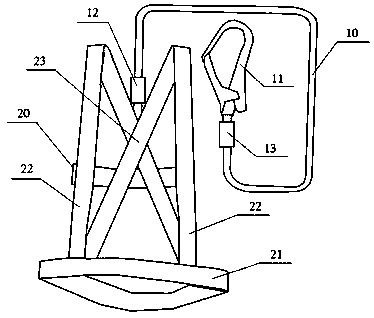

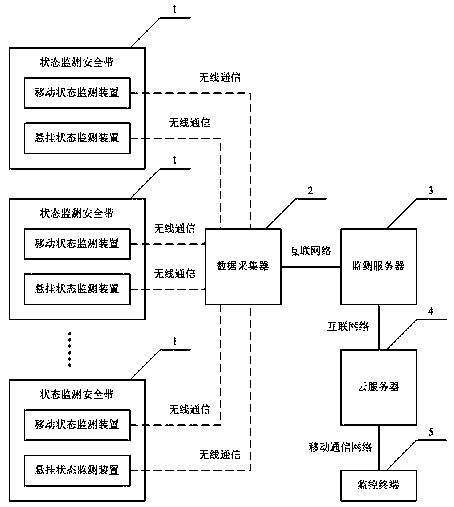

[0041] S1, install safety belt condition monitoring system, described safety belt condition monitoring system comprises such as figure 2 As shown in the state monitoring safety belt, as well as the data collector and the monitoring server, the state monitoring safety belt includes a safety belt body for wearing, and a safety lanyard, and the hooking fixed end of the safety lanyard is provided with a The hook connected to the fixed point, the wearing connection end of the safety lanyard is used to be fixedly connected to the safety belt body, the wearing connection end of the safety lanyard is also fixedly installed with a mobile state monitoring device, the articulated connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com