Filtration fabric recycling utilization device for copper alloy production line

A filter cloth and production line technology, which is applied in the field of filter cloth recycling devices in copper alloy production lines, can solve problems such as hidden safety hazards, poor working conditions, and low efficiency, and achieve the goals of reducing labor intensity, reducing hidden dangers of safety accidents, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

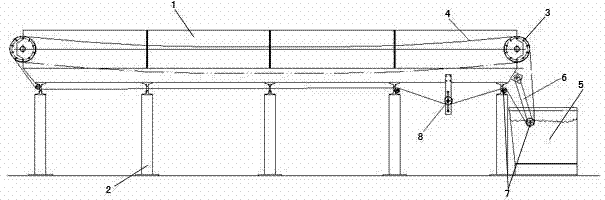

[0013] Such as figure 1 As shown, a filter cloth recycling device for a copper alloy production line according to the present invention includes a filter 1 and a cylindrical support frame 2 for supporting the filter 1. The inlet and outlet ends of the filter 1 are provided with a For the transmission idler 3, the transmission idler 3 is driven by the filter cloth 4, and overlapped to form an endless belt; the outlet end of the filter 1 is provided with a copper oxide recovery box 5, and the copper oxide recovery box 5 is provided with a There is a rotating arm 6 connected to the filter 1, the lower end of the rotating arm 6 is provided with a guide wheel 7, and extends into the copper oxide recovery box 5; a gravity tension pressing wheel 8 is fixed on the filter 1 directly below the outlet, The top of the support frame 2 on both sides of the gravity tension pressure wheel 8 is provided with a guide wheel 7, and the support frame 2 supported at the inlet end of the filter 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com