Bendable air gun

A bending and air gun technology, which is applied in the direction of cleaning methods using gas flow, casting molding equipment, metal processing equipment, etc., can solve problems such as uncleanness and air guns that cannot be cleaned, so as to improve quality and efficiency, ensure safety, and avoid simultaneous The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

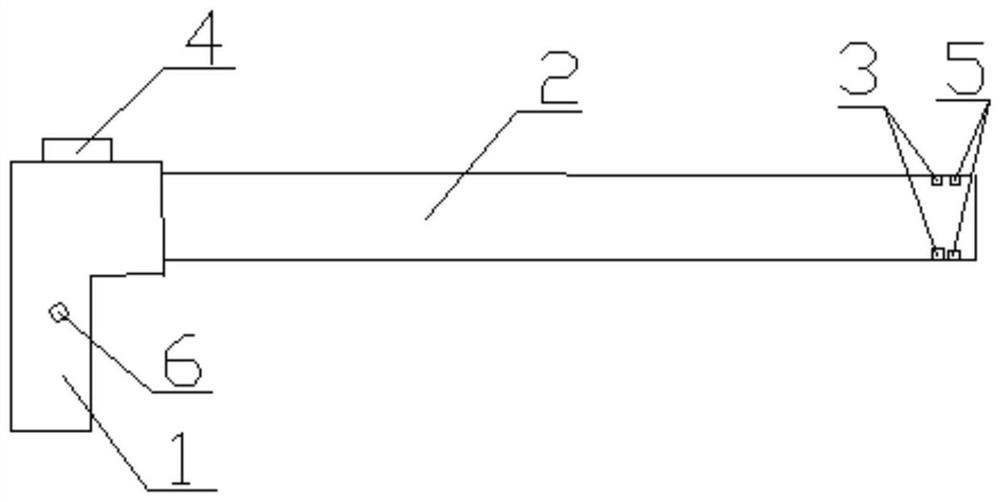

[0026] In a specific example, see figure 1 , a bendable air gun, the bendable air gun includes a handle 1, a bendable nozzle 2, an LED light 3, a display screen 4, a miniature camera 5 and a switch button 6; one end of the bendable nozzle 2 is sleeved with Handle 1; The other end outer wall of described bendable gun mouth 2 is equipped with miniature camera 5; Described four circles small-sized LED lights 3 are installed in the bottom of described miniature camera 5; The length of described bendable gun mouth 2 is 400mm, The inner diameter is 20mm, and the wall thickness is 10mm; the inner diameter of the handle 1 is 20mm; the power of each LED lamp 3 is 1w, and 16 LED lamps 3 are installed in total; the axial length of the LED lamp 3 does not exceed 20mm. The LED lamp 3 is powered by a DC ±12V storage battery.

[0027] In a specific embodiment, the switch button 6 is installed on the side of the handle 1, and the switch button 6 is used to control the on and off of the LED l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com