Adapter capable of controlling pressure

A conversion joint and pressure technology, applied in valve operation/release devices, valve details, multi-way valves, etc., can solve problems such as safety accidents, increased production costs, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

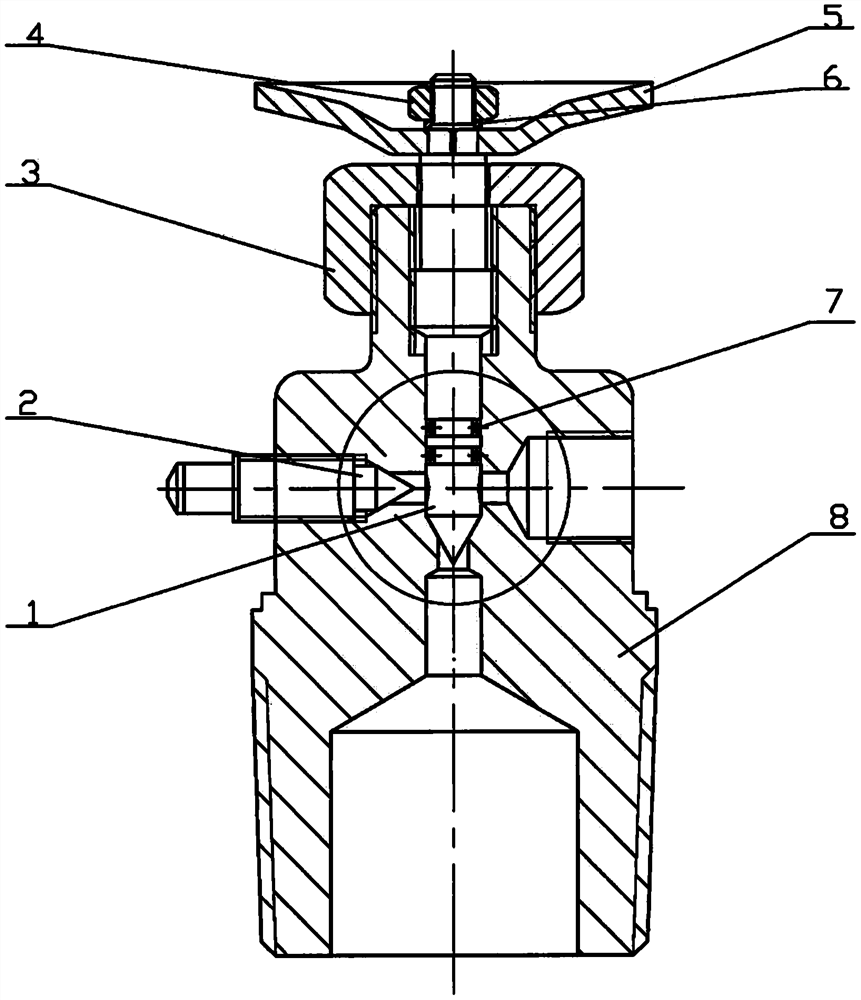

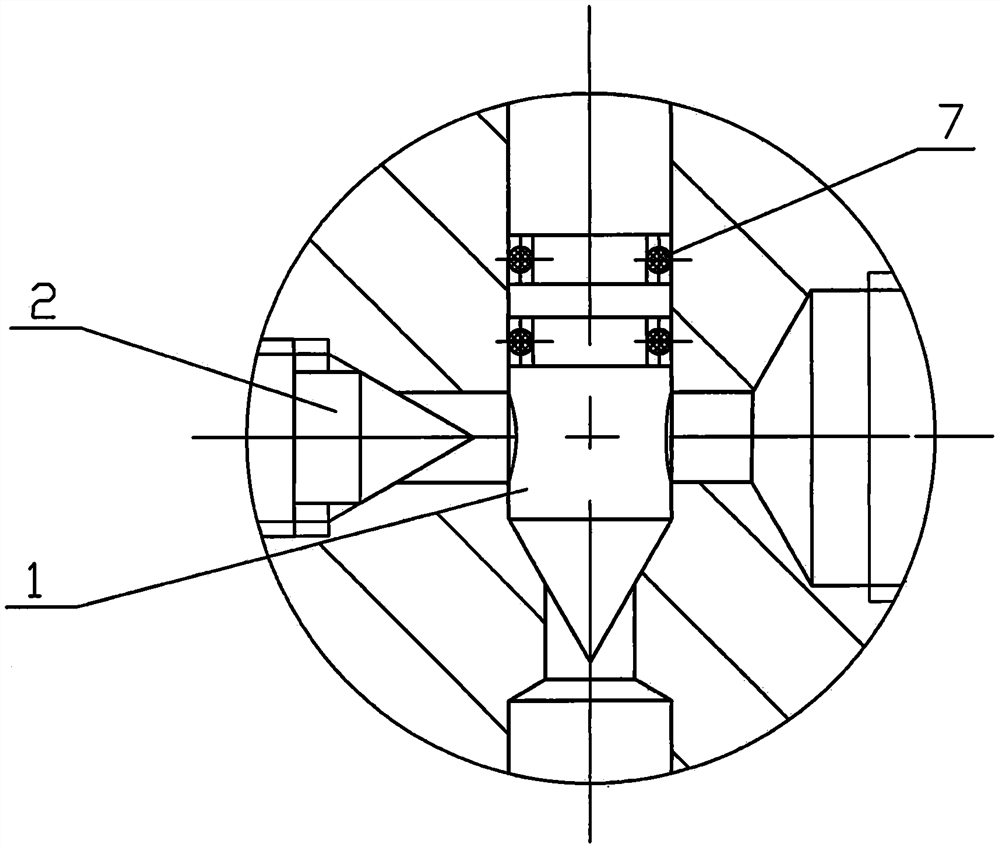

[0011] Attached below figure 1 , the specific embodiment of the present invention will be further described.

[0012] Such as figure 1 As shown, the valve needle 1 is threaded to the adapter body 8, and there are two ring grooves on the valve needle 1, which are used to place the O-ring 7 to enhance the sealing performance of the stop valve; one end of the adapter body 8 is processed into a taper External thread, the other external thread is the same type as the internal thread of shell cap 3; shell cap 3 is tightened on the adapter body 8 to prevent valve needle 1 from leaving the adapter body 8, handwheel 5 is placed on valve needle 1, and nut 4 is tightened The valve needle 1 is used to fix the handwheel 5, the gasket 6 is placed between the handwheel 5 and the nut 4, and the valve needle 1 can be opened or closed by turning the handwheel 5; The opposite internal thread is used to place the valve needle 2 and connect the pressure gauge.

[0013] The operation implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com