Special mechanical clearing device and clearing method for mine silo

A mine storage and machinery technology, applied in the field of mining construction equipment, can solve the problems of high safety risk of collapse and falling, difficulty in manual clearance and high risk, and achieve the effects of reducing hidden dangers of safety accidents, efficient and fast clearance, and safe and reliable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment and in conjunction with accompanying drawing, the present invention is further described:

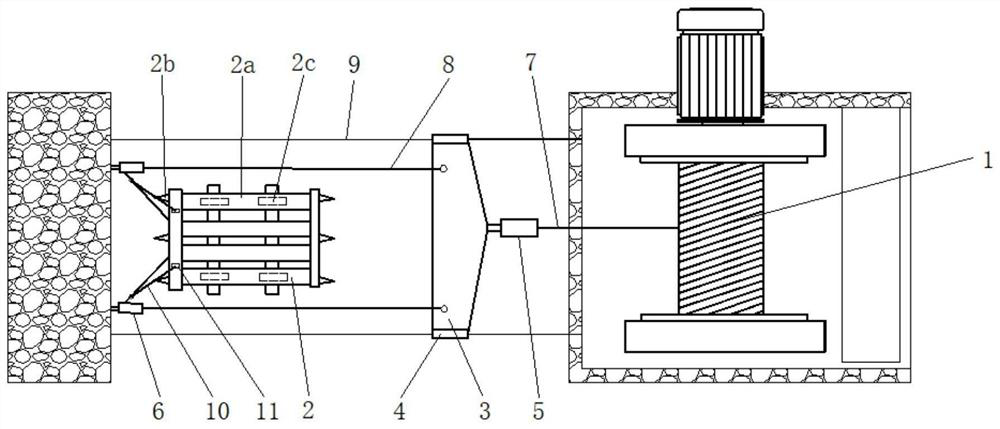

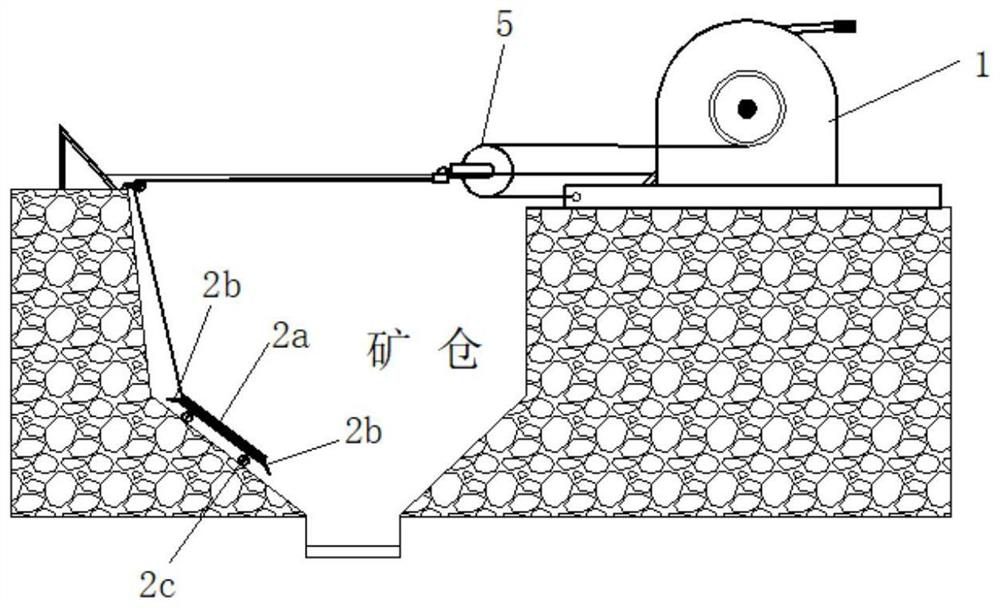

[0022] combine figure 1 — figure 2 As shown in the figure, a special mechanical clearance device for mines is mainly composed of a winch 1, a rake 2, a sliding steel plate 3, a guide pipe 4, a movable pulley 5, a guide pulley 6, a main wire rope 7, a traction wire rope 8, a guide wire rope 9, and a protection wire rope 10 compositions.

[0023] The winch 1 is fixedly installed on the rear side of the top of the mine bin, and the two guide pulleys 6 are symmetrically installed on the front side of the top of the mine bin at left and right intervals.

[0024] A guide wire rope 9 is fixed on the left and right sides of the top of the mine bin, and the front and rear ends of each guide wire rope 9 are respectively fixed on the front and rear sides of the mine bin.

[0025] The main body of the rake 2 is a welded rectangular steel rake frame 2a. A row of rake t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com