Construction site dust suppressant and preparation method thereof

A technology for construction sites and dust suppressants, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of wasting municipal tap water and unsatisfactory effects, and achieve simple construction, excellent dust suppression effect, and long dust suppression period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

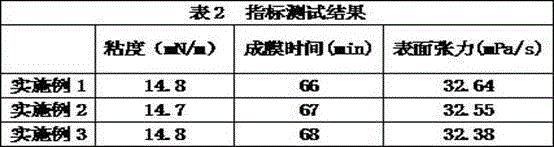

Examples

Embodiment 1

[0018] (2) Take 4 grams of zinc dialkyldithiophosphate, 6 grams of aluminum starch octenyl succinate, 1 gram of sodium dodecyl sulfonate, 8 grams of zinc stearate, and 6 grams of propyltrimethoxysilane Add to 25 grams of deionized water; heat to 50~58°C, and stir for 40~50 minutes under ultrasonic conditions;

[0019] (3) Stir the mixture in step (1) and the mixture in step (2) evenly, and vacuum-dry at 20°C to obtain the obtained product.

[0020] Example 2: (1) 68 grams of high-substituted hydroxypropyl cellulose, 53 grams of lignocellulose, and 25 grams of polylactic acid were made into a powder of 200 mesh or more, and stirred and mixed evenly;

Embodiment 2

[0021] (2) Take 5 grams of zinc dialkyldithiophosphate, 6 grams of aluminum starch octenyl succinate, 2 grams of sodium dodecyl sulfonate, 10 grams of zinc stearate, and 10 grams of propyltrimethoxysilane Add to 30 grams of deionized water; heat to 50~58°C, and stir for 40~50 minutes under ultrasonic conditions;

[0022] (3) Stir the mixture in step (1) and the mixture in step (2) evenly, and vacuum-dry at 20°C to obtain the obtained product.

[0023] Example 3: (1) 60 grams of high-substituted hydroxypropyl cellulose, 48 grams of lignocellulose, and 18 grams of polylactic acid were made into a powder of 200 mesh or more, and stirred and mixed evenly;

Embodiment 3

[0024] (2) Take 3 grams of zinc dialkyl dithiophosphate, 4 grams of aluminum starch octenyl succinate, 1 gram of sodium dodecyl sulfonate, 6 grams of zinc stearate, and 6 grams of propyltrimethoxysilane Add to 20 grams of deionized water; heat to 50~58°C, and stir for 40~50 minutes under ultrasonic conditions;

[0025] (3) Stir the mixture in step (1) and the mixture in step (2) evenly, and vacuum-dry at 20°C to obtain the obtained product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com