Spray gun station

A spray gun and pipeline technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separating agents, can solve the problems of high fan power, low capture rate, and high energy consumption, achieving good results, low operating costs, and Arrange flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

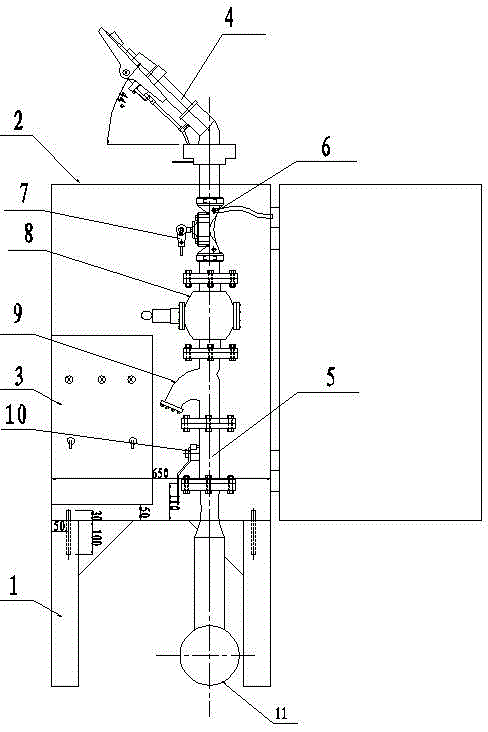

[0008] Such as figure 1 As shown, the present invention comprises a spray gun station platform 1, a protective box 2 is set above the spray gun station platform 1, an electric control box 3 is set in the inner cavity of the protective box 2, and a self-oscillating head spray gun 4 is arranged above the protective box 2, and a self-oscillating head The rear end of the spray gun 4 is connected to the spray gun pipeline 5, and the spray gun pipeline 5 is placed in the protection box 2. On the spray gun pipeline 5, an automatic drain valve 6, a solenoid valve 7, a pressure reducing valve 8, and a filter 9 are arranged in sequence from top to bottom. And the ball valve 10; the lower end of the spray gun pipeline 5 is connected to the main water supply pipeline 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com