Compound chemical dust suppressant as well as preparation method and application thereof

A dust suppressant and composite technology, which is applied in the field of composite chemical dust suppressant and its preparation, can solve many problems, and achieve the effect of no secondary pollution, good spraying effect, and simple on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

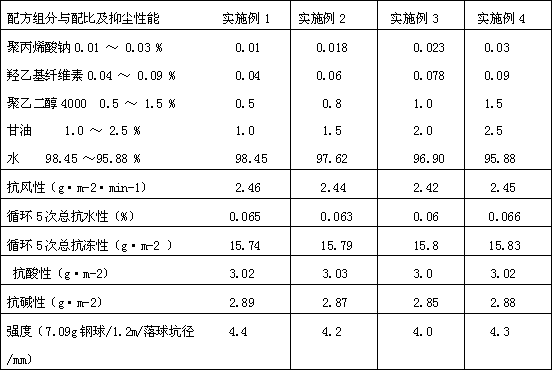

[0017] See Table 1 for the formula components and proportioning ratio of the embodiment and its dust suppression performance.

[0018] The preparation method of the embodiment: the solid formula components are formulated into the following aqueous solutions, mixed according to the mass content ratio of each component when used, and glycerin is added, stirred evenly, and the product is obtained.

[0019] (1) Sodium polyacrylate is prepared into a 0.12% solution, and sodium polyacrylate is added to the measured water with a high-speed stirring device, stirred at room temperature for 3 to 4 hours, until a uniform transparent liquid is set aside;

[0020] (2) Hydroxyethyl cellulose is made into a 2% solution, and carboxymethyl cellulose is added to the measured water with a high-speed stirring device, and stirred at room temperature for 3 to 4 hours until it becomes a uniform transparent liquid. Store at low temperature for later use;

[0021] (3) Make a 6% solution of polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com