Dust suppression device for slag-tapping or ash-discharge process of power plant

A technology of power plants and injection devices, which is applied in the field of dust removal, can solve problems such as poor operation, large water consumption, and difficult cleaning, and achieves the effect of significant dust suppression, low water consumption, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

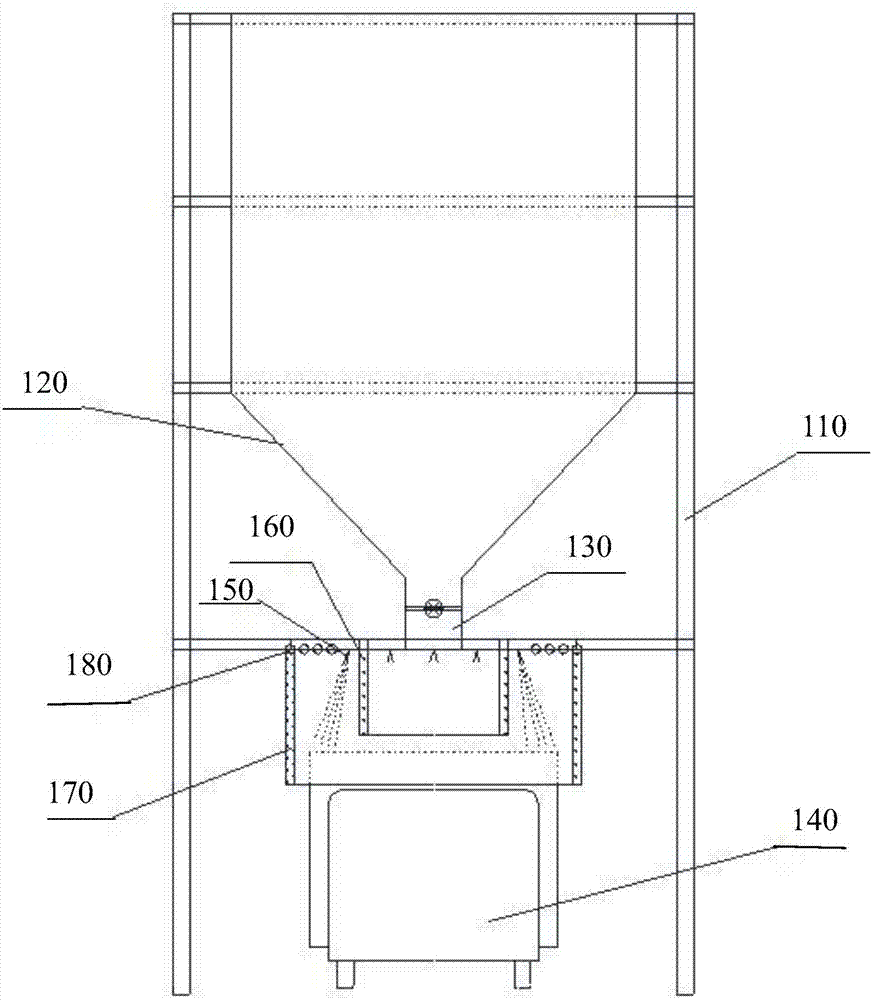

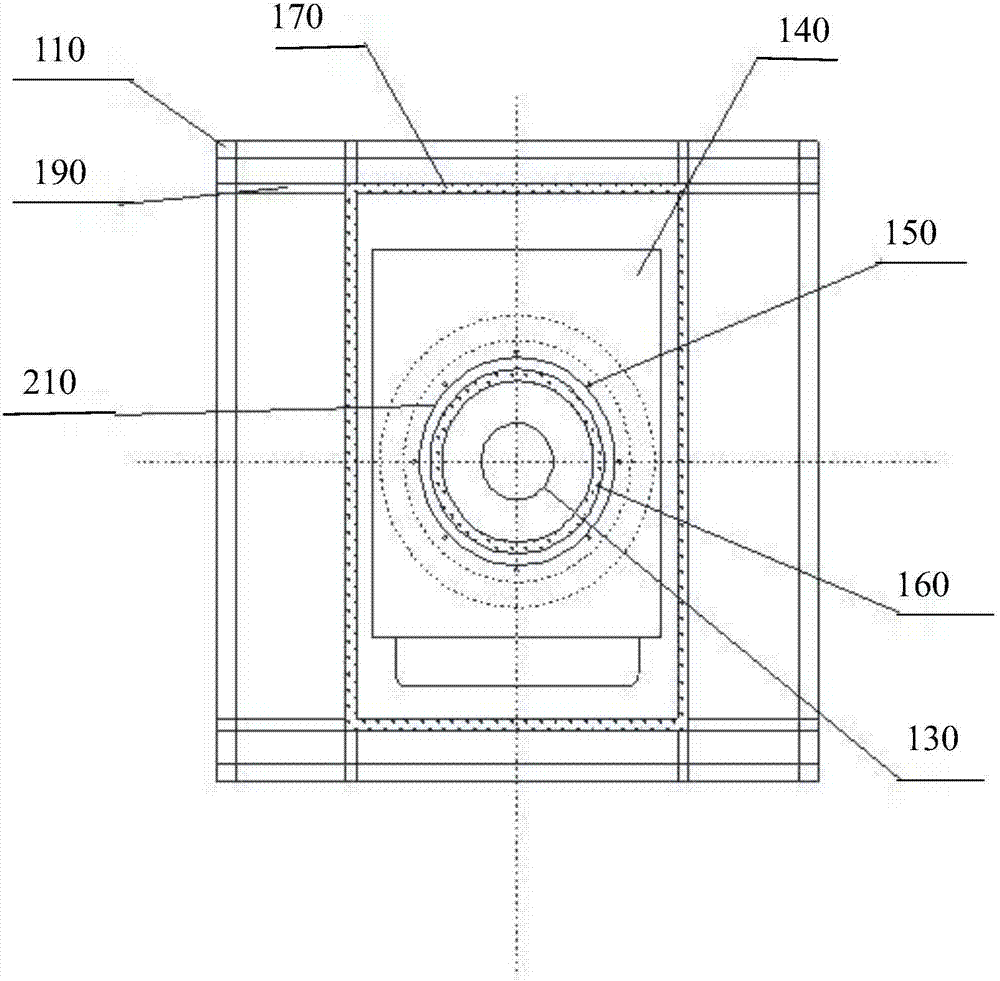

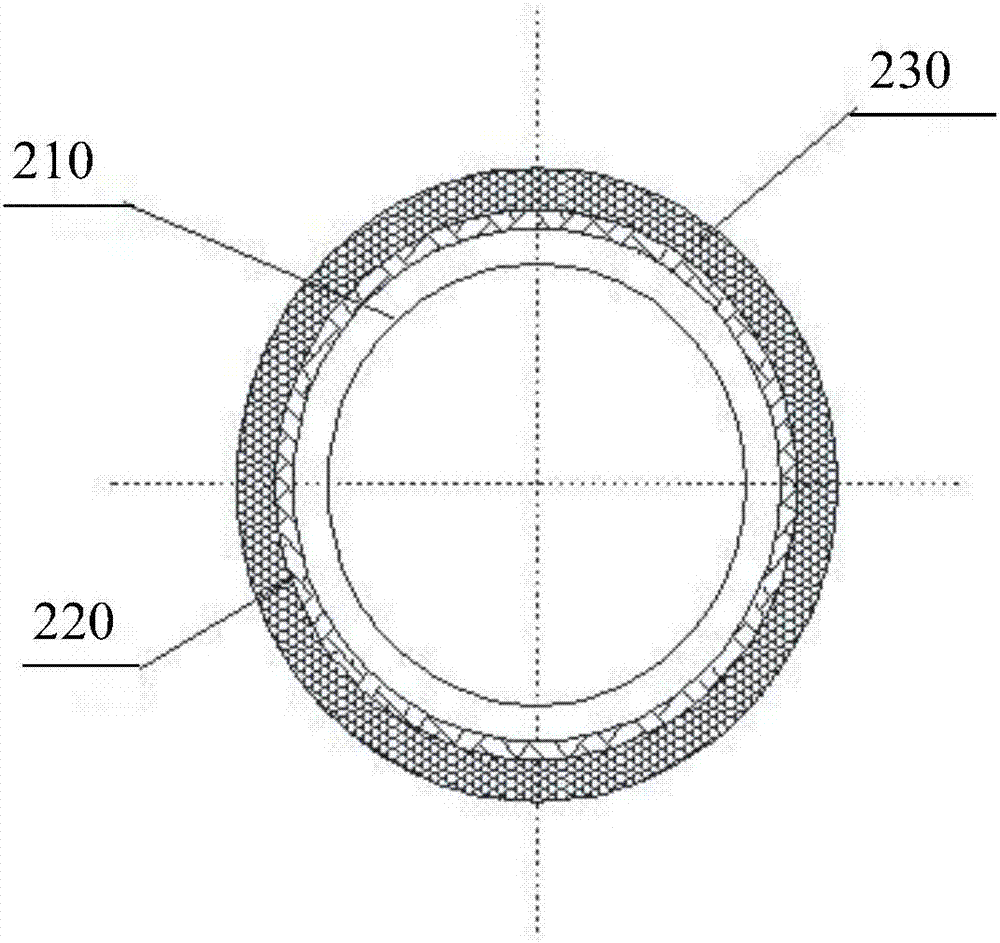

[0031] like figure 1 As shown, the present invention provides a dust suppression device in the slag discharge or ash discharge process of a power plant, including: a steel frame 110, a slag bin 120, a slag discharge port 130, a slag receiving vehicle 140, an atomizing nozzle 150, and an inner dust suppression soft screen 160. Outer layer dust suppression soft screen 170, pull ring 180, self-made steel frame 190, ring distribution pipe 210, heat tracing device 220 and insulation material 230.

[0032] Wherein, a slag bin slag outlet 130 is provided below the slag bin 120, an inner layer dust suppression soft screen 160 is arranged under the slag bin slag outlet 130, an outer layer dust suppression soft screen 170 is arranged outside the slag receiving vehicle 140, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com