Tailing surface layer consolidation material based on lysinibacillus sphaericus and application thereof

A technology of Bacillus lysine and consolidation materials, applied in the application, soil conditioning materials, infrastructure engineering and other directions, can solve the problems of inability to achieve the purpose of dust prevention, complicated construction technology, limited popularization and application, etc., and achieve good dust suppression. Effect, solve the effect of complex production process and environmental protection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

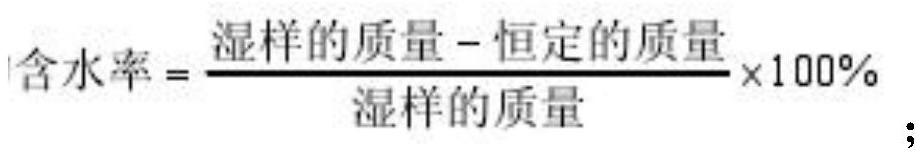

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a tailings surface consolidation material based on Bacillus sphaericus, including the following components in terms of mass percentage: 30% of metal tailings sand, 3% of Bacillus spheroidus liquid, Urea 1%, anhydrous magnesium chloride 10%, potassium alginate 6%, water 50%.

[0027] The above-mentioned preparation method of the tailings surface consolidation material based on Bacillus sphaericus comprises the following steps:

[0028] 1) First, L.sphaericus (purchased from China Marine Microorganism Culture Collection Management Center) was expanded and cultured at 30°C with 2216E medium to obtain a bacterial liquid, and then the obtained bacterial liquid was centrifuged Collect the thalline, then freeze-dry the collected thalline to obtain the freeze-dried powder of the spherical lysine bacillus, and finally add the spherical lysine bacillus freeze-dried powder into normal saline to prepare the spherical lysine bacillus bacterium liquid ( OD60...

Embodiment 2

[0033]This embodiment provides a tailings surface consolidation material based on Bacillus sphaericus, including the following components in terms of mass percentage: 35% of metal tailings sand, 5% of Bacillus spheroidus bacteria liquid, Urea 5%, anhydrous magnesium chloride 8%, potassium alginate 1%, water 46%.

[0034] The preparation method of the above-mentioned tailings surface consolidation material based on Bacillus sphaericus is the same as that in Example 1.

Embodiment 3

[0036] This embodiment provides a tailings surface consolidation material based on Bacillus sphaericus, including the following components in terms of mass percentage: 40% of metal tailings sand, 8% of Bacillus spheroidus bacteria liquid, Urea 2%, anhydrous magnesium chloride 3%, potassium alginate 2%, water 45%.

[0037] The preparation method of the above-mentioned tailings surface consolidation material based on Bacillus sphaericus is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com