A coal-fired power plant ash storage yard and industrial tailings dust suppression process and device

A technology for coal-fired power plants and industrial tailings, which is applied in the fields of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor control effect, waste of resources, pollution of the environment, etc., and achieve better dust suppression effect. , The effect of high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

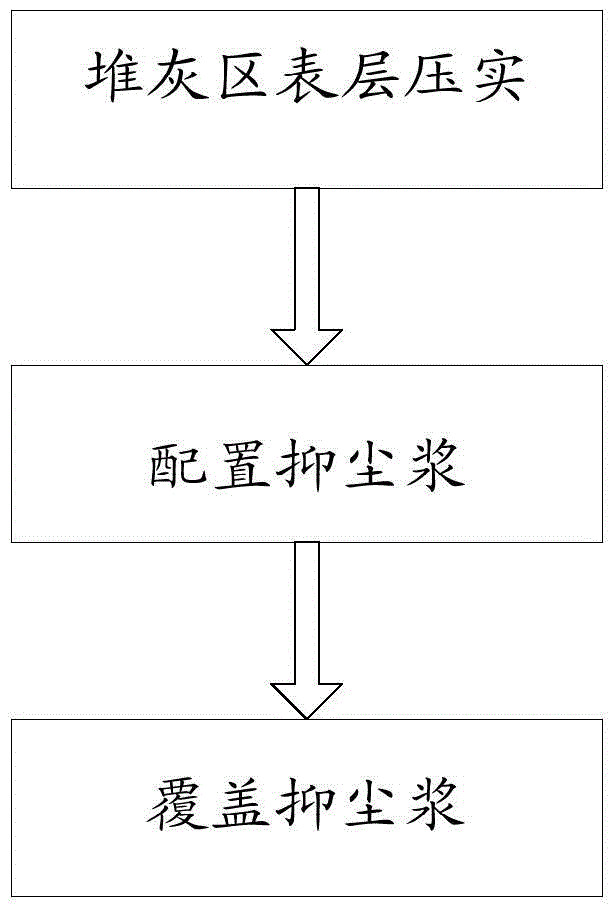

[0056] Such as Figure 1-6 Shown, a coal-fired power plant ash storage yard and industrial tailings dust suppression technology, including the following steps:

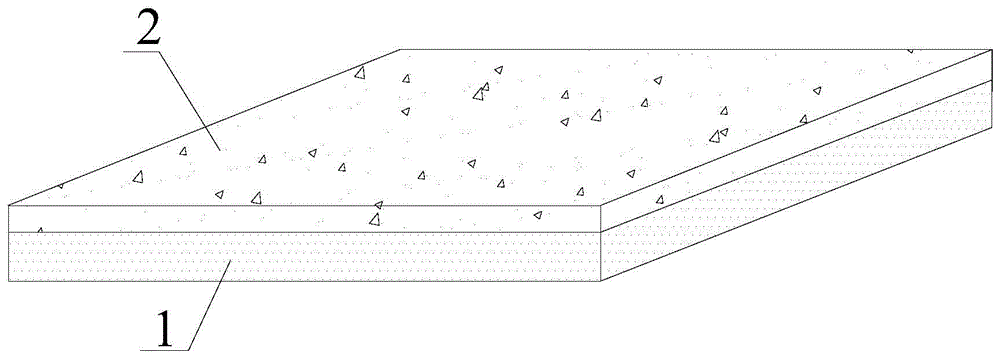

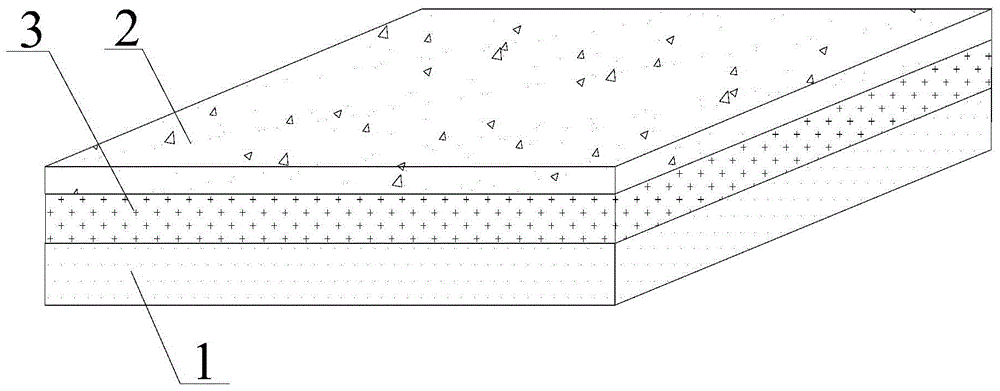

[0057] Surface compaction in ash pile area 1: spray water on the surface layer of the ash pile layer, and after the surface layer absorbs water, use mechanical compaction or water stabilization and compaction;

[0058] Configure dust suppression slurry 2: the raw material of dust suppression slurry 2 is mixed with water, cement, aggregate and auxiliary materials;

[0059] Cover the dust suppression slurry 2; after the surface layer of the ash pile area 1 is compacted, spray the dust suppression slurry 2 on it, and the dust suppression slurry 2 covers the ash pile area 1.

[0060]Preferably, the volume ratio of water, cement, aggregate and auxiliary mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com