High-polymer dust suppressant

A dust suppressant and polymer technology, applied in the field of polymer dust suppressants, can solve the problems of not being able to exert dust suppressing effect for a long time, no improvement in wind erosion resistance, limited dust suppression ability, etc., to achieve good resistance to wind erosion, inhibit open source The effect of fugitive dust and rapid dust suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add an appropriate amount of water into the reaction kettle, add 1% ammonium persulfate aqueous solution and 1% potassium persulfate aqueous solution, stir and heat, raise the temperature to 60~80°C, add sodium dodecylbenzenesulfonate into the reaction kettle, and keep the temperature constant Stir for 30~45min; add glycerol and op-10, stir at constant temperature for 30~45min; add 10% acrylamide aqueous solution, add 1% ammonium persulfate aqueous solution and 1% potassium persulfate aqueous solution again, and react at constant temperature for 1 ~3h, add water glass, stir for 30~45min, stop stirring after mixing evenly, and cool naturally. The obtained inhibitor number is A

[0031] The mass ratio of sodium dodecylbenzenesulfonate, glycerol, acrylamide, op-10, ammonium persulfate, potassium persulfate, water glass and water is 3:15:8:40:0.4:0.6:4: 30.

Embodiment 2

[0033] Place the precursor sodium dodecylbenzenesulfonate, glycerin and acrylamide under nitrogen protection respectively, microwave output power 800W, frequency 2450MHz, treat for 25min, add appropriate amount of water to the reaction kettle, add 1% ammonium persulfate Aqueous solution and 1% potassium persulfate aqueous solution, stir and heat, raise the temperature to 60~80°C, add microwave-treated sodium dodecylbenzenesulfonate into the reaction kettle, stir at constant temperature for 30~45min; add microwave-treated acrylic acid Triol and op-10, stir at constant temperature for 30~45min; prepare microwave-treated acrylamide into a 10% aqueous solution, add acrylamide aqueous solution, add 1% ammonium persulfate aqueous solution and 1% potassium persulfate aqueous solution , constant temperature reaction for 1~3h, add water glass, stir for 30~45min, stop stirring after mixing evenly, and cool naturally. Put the product at an air pressure of 600~700Pa, the volume ratio of n...

Embodiment 3

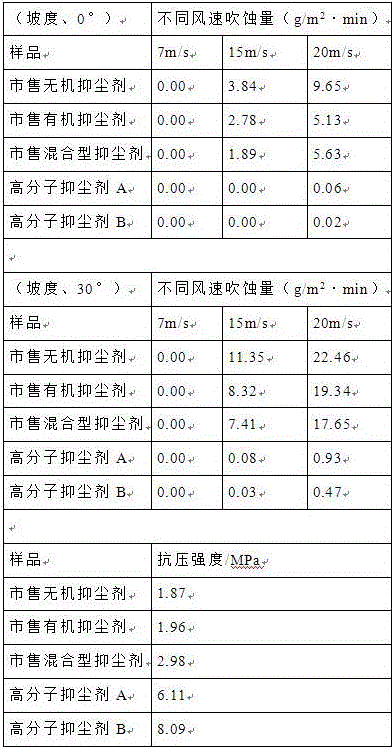

[0036] The macromolecule inhibitors A and B prepared by the present invention are carried out wind erosion resistance wind tunnel test, and pressure resistance test, and are carried out with commercially available inorganic dust suppressant, commercially available organic dust suppressant and commercially available hybrid dust suppressant. Compared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com