Surface growth type culture plate having sandwich structure, surface growing culture system and surface growing culture method

A technology of surface growth and sandwich structure, applied in biochemical equipment and methods, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve the problem of uneven surface humidity of filter cloth and fiber fabrics, Intolerance to recycling, the culture system has not entered large-scale production and other problems, to achieve the effect of improving the growth rate and quality of microalgae, improving the utilization rate of light energy, and achieving full growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

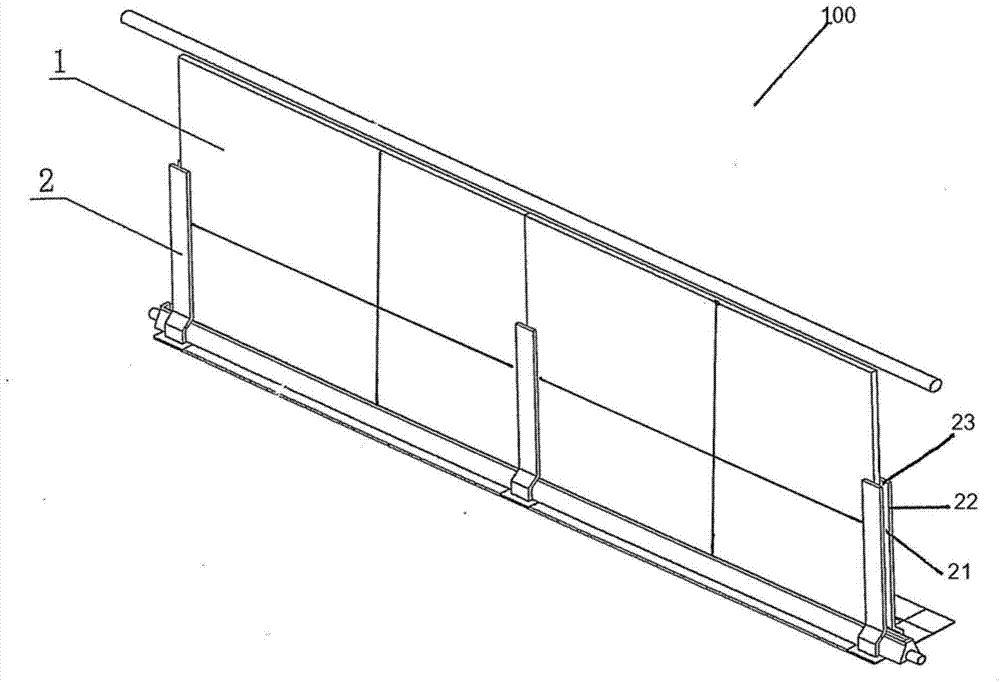

[0067] combine Figure 4 One example of the culture system of the present invention is shown.

[0068] Figure 4 The surface growth culture system 1000a can include multiple such as image 3 Shown are the culture units 100 , the light source device 8 disposed between the culture units 100 , and the culture solution circulation device 9 a for supplying the culture solution to the culture units 100 .

[0069] Figure 4 A plurality of culture units 100 in the set are arranged parallel to each other and separated by a distance. At least one light source device 8 is arranged between every two culture units 100 . The light source device can be a double-sided light source to irradiate the culture units on both sides. The light source device 8 can also be a single-sided light source as required.

[0070] Figure 4 The surface growth type culture system 1000a of the present invention comprises a culture solution circulation device 9a, and the culture solution circulation device ...

Embodiment 2

[0074] combine image 3 and Figure 5 Another culture system of the present invention is described. Figure 5 are according to the invention including image 3 A schematic diagram of another embodiment 1000b of a surface-grown culture system of a culture unit. and Figure 4 Similar to the illustrated embodiment, the culture system 1000b may also include one or more image 3 The culture unit 100. Specifically, the culture system 1000b may include a culture unit 100, a culture solution recovery device 3, a liquid supply device 4, a culture solution pool 6, a pressure tank 11, a compressed air source 12, a liquid level gauge 13, a shut-off valve 14, and a shut-off valve 15 , pressure reducing valve 16, exhaust valve 17, and pressure gauge 18.

[0075] Figure 5 As shown, the surface growth culture system 1000b includes a culture fluid circulation device 9b, and an air compression method may be used in the culture fluid circulation device 9b. The device used in this air co...

Embodiment 3

[0098] Embodiment 3 cultivation test

[0099] 3.1. Culture medium composition

[0100] Taking the composition of the culture medium for Chlorella culture as an example, see Table 2 below.

[0101] Table 2 The composition of the culture medium for Chlorella culture

[0102] components

Usage amount

NaNO 3

1mL / L

25g / 100mldH 2 o

K 2 HPO 4

1mL / L

7.5g / 100mldH 2 o

MgSO 4 ·7H 2 o

1mL / L

7.5g / 100mldH 2 o

CaCl 2 2H 2 o

1mL / L

2.5g / 100mldH 2 o

K H 2 PO 4

1mL / L

17.5g / 100mldH 2 o

NaCl

1mL / L

2.5g / 100mldH 2 o

Na 2 CO 3

1mL / L

0.2g / 100mldH 2 o

FeCl 3 ·6H 2 o

1mL / L

0.05g / 100mldH 2 o

EDTA-Fe

1mL / L

trace metal solution

1mL / L

Soil Extract

40mL / L

[0103] Table 3 Recipe of trace metal solution

[0104] components

h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com