Patents

Literature

46results about How to "Reduce energy consumption for concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

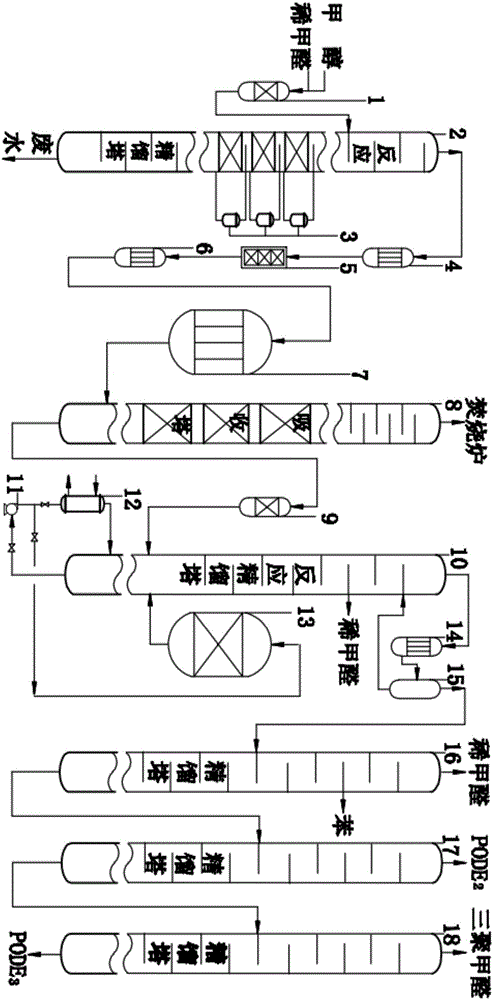

Method for synthesizing trioxymethylene by methanol through condensation, oxidation and polycondensation

InactiveCN106256822AEasy to separateReduce separation energy consumptionOrganic chemistryChemical industryHigh concentrationHigh energy

The invention relates to a method for synthesizing trioxymethylene by methanol through condensation, oxidation and polycondensation. According to the invention, methanol and dilute formaldehyde with concentration of 5-30% separated from a trioxymethylene apparatus are taken as raw materials to synthesize methylal with concentration of 85-99.9%; methylal and air are subjected to catalyst oxidation to generate formaldehyde through an iron molybdenum method, through refining water and methylal unit tower waste water absorption, a formaldehyde aqueous solution with concentration of 70% is generated; high-concentration formaldehyde is introduced into a trioxymethylene synthetic tower, and the trioxymethylene is synthesized under existence of a strong-acid cation exchange resin catalyst, and trioxymethylene with content of 99.9% can be obtained through steps of rectification and concentration, extraction, rectification, and purifying. The method solves the problems of low conversion rate, selectivity and low yield during a trioxymethylene production process, solves the problems of low catalyst reaction efficiency and corrosivity, and solves the problems of complex technology and high energy consumption. The method provides good raw materials for producing PODE, and realization of industrialization of PODE can solve the problem of excess production capacity of methanol in our country.

Owner:XIAN SHANGHUA TECH DEV CO LTD

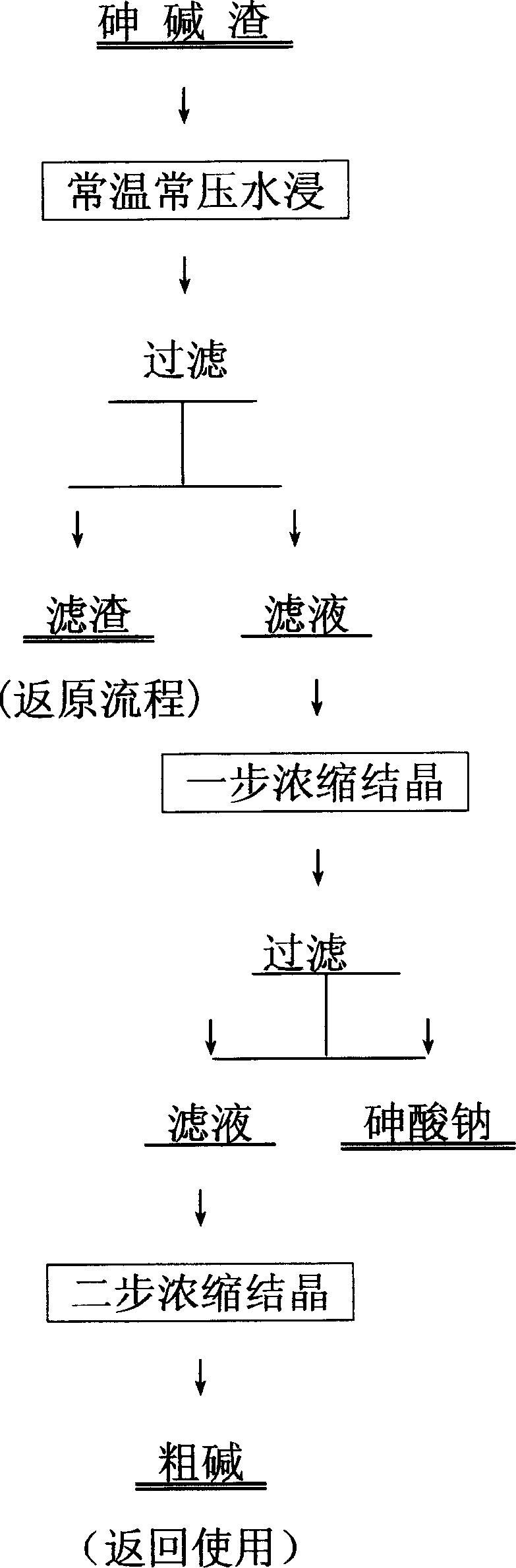

Method for separating and recovering sodium arsenate and alkali by fractional crystallization method

InactiveCN1594090AIncrease Concentration Energy ConsumptionShort processArsenites/arsenatesSodium/potassium compoundsChemistryMother liquor

The invention provides a method for separating and recovering sodium arsenate and alkali by fractional crystallization method which consists of, condensing the arsenic alkaline residue infusion, cooling down to below room temperature, stewing for 2 hrs, filtering to obtain sodium arsenate, concentrating the crystallization mother liquor, and calcining the crystallized product.

Owner:广西华锡集团股份有限公司

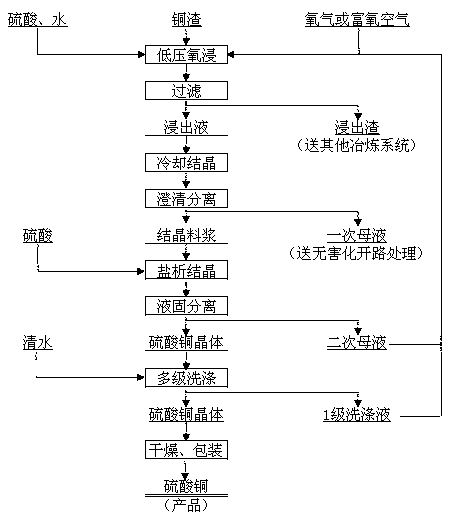

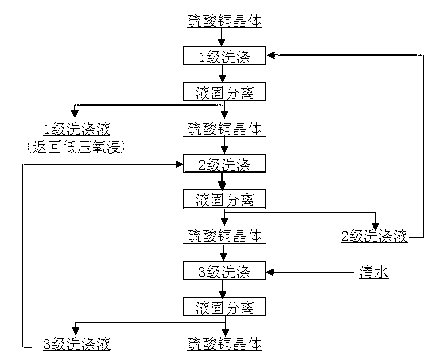

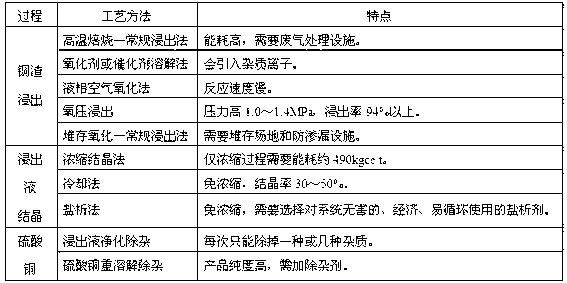

Method for producing high-quality copper sulfate through low-pressure oxygen leaching of copper slag

ActiveCN103074499AHigh product purityNo addedProcess efficiency improvementCopper sulfatesCOPPER SULFATE CRYSTALSLeaching (metallurgy)

The invention relates to a method for producing high-quality copper sulfate through low-pressure oxygen leaching of copper slag. A copper-bearing material with metallic copper or cuprous oxide content greater than 15wt% serves as a raw material, and the method comprises the steps of copper slag or spongy copper slag pickling of zinc hydrometallurgy. A dilute sulphuric acid solution is adopted for low-pressure oxygen leaching of the raw material, an obtained leachate is subjected to combined crystallization including cooling crystallization and salting-out crystallization, a copper sulfate crystal is obtained after liquid-solid separation, and dried after multistage washing, and copper sulfate meeting requirements of above a premium grade specified in YS / T 94-2007 is obtained.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM +1

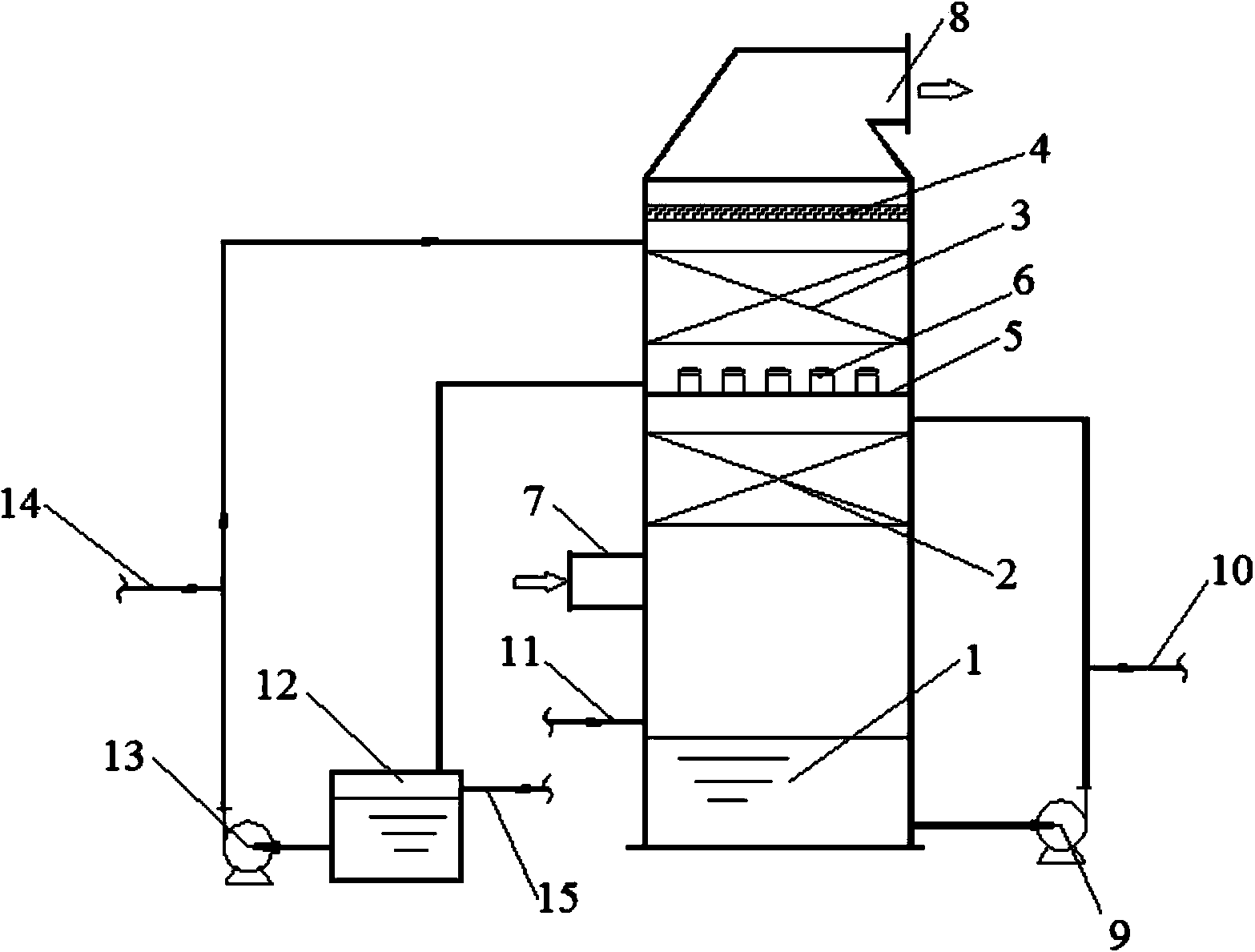

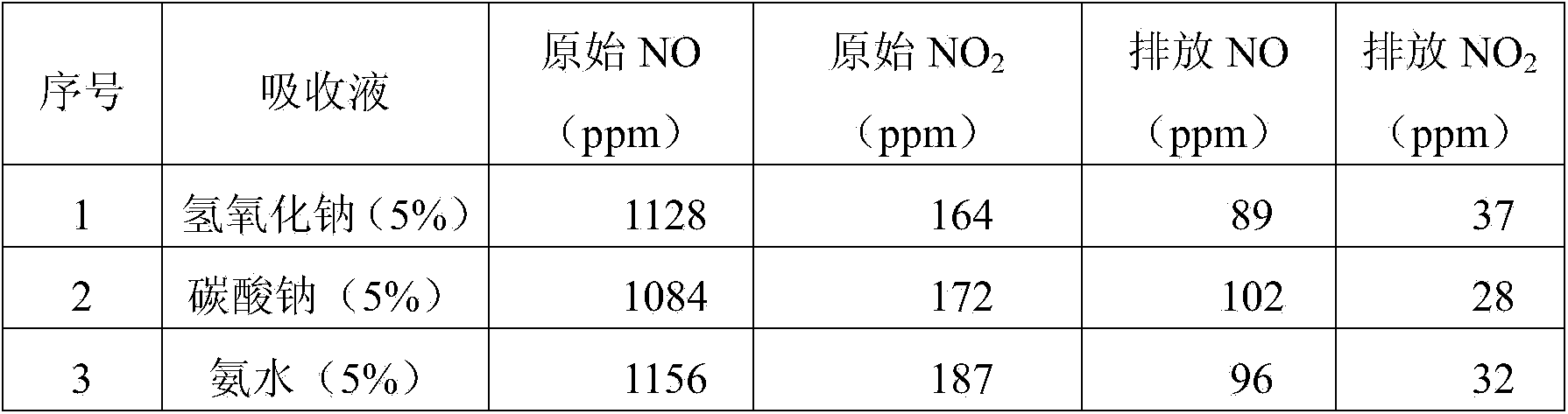

Process and device for treating nitric oxide in tail gas generated in nitric acid and nitrate production

InactiveCN103933848AReduce purchasing costsLow running costDispersed particle separationAlkali metal nitrate preparationNitriteEmission standard

The invention discloses a process and a device for treating nitric oxide in tail gas generated in the nitric acid and nitrate production. The process comprises the following steps: (1) carrying out tempering reaction on the tail gas generated in the the nitric acid and nitrate production by virtue of a 30-68% nitric acid solution, and controlling the volume percentage of NO to NO2 in the tempered tail gas to be 0.95-1.05; and (2) carrying out absorption reaction on the tempered tail gas by virtue of an alkaline absorption liquid, so as to generate nitrate and nitrite. The device comprises an absorption tower which comprises an oxidized-nitric-acid circulating storage tank, a tail gas tempering region, an alkali absorption region and a demisting region from bottom to top, wherein the tail gas tempering region and the alkali absorption region are separated by a tower board, air hoods are uniformly distributed on the tower board, a tail gas inlet is formed in the lower end of the tail gas tempering region, and a tail gas outlet is formed above the demisting region. The process and the device have the advantages that the efficiency is high, the cost is low, the nitric oxide in the tail gas can be recycled, and the tail gas processed by virtue of the process and the device can meet an emission requirement of 'emission standard of pollutants for nitric acid industry'.

Owner:北京中环新锐环保技术有限公司 +1

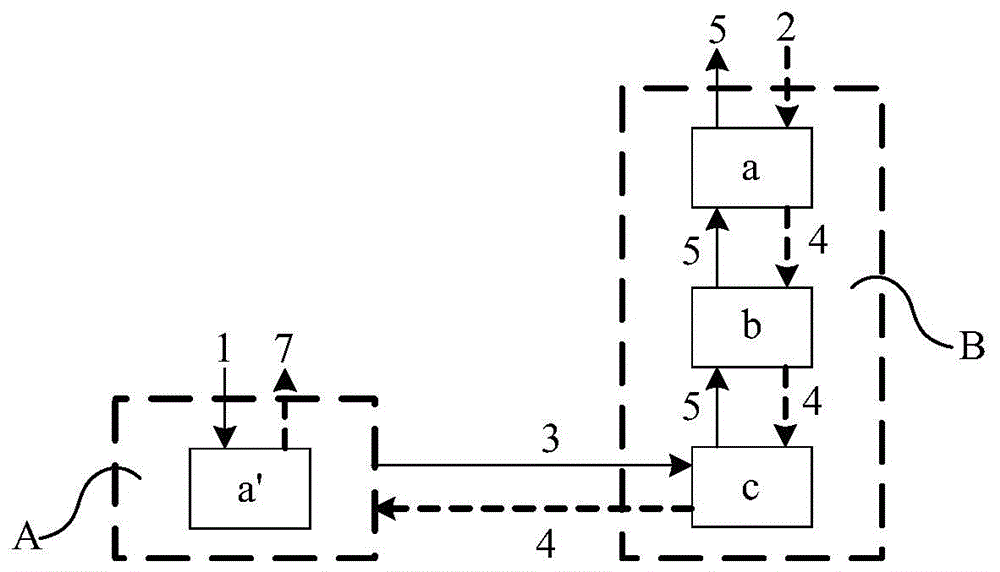

Recovery method for potassium catalyst in coal catalytic gasification ash

ActiveCN104815673ALow water consumptionReduce energy consumption for concentrationCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsChemistryDigestion

The invention relates to the field of coal catalytic gasification, particularly to a method for recovery of potassium catalyst in coal catalytic gasification ash. While reducing water consumption and lowering energy consumption, the method can enhance the total recovery rate of potassium in ash, and overcomes the defects of large water consumption, low concentration of potassium recovered solution, high energy consumption of the evaporation and concentration process in the recovery technology of the prior. The recovery method provided by the embodiment of the invention includes: a washing section, and a digestion section containing at least two-stage digestion reaction. In the washing section, coal catalytic gasification ash is subjected to washing, and the obtained washing slag enters the reactor of the last stage digestion reaction to serve as the raw material of the last stage digestion reaction. In the digestion section, the potassium solution generated by a former stage digestion reaction enters the reactor of a next stage digestion reaction, the solid product enters the reactor of the former stage digestion reaction to serves as the raw material of the former stage digestion reaction, and the potassium solution in the reactor of the last stage digestion reaction enters the washing section.

Owner:ENN SCI & TECH DEV

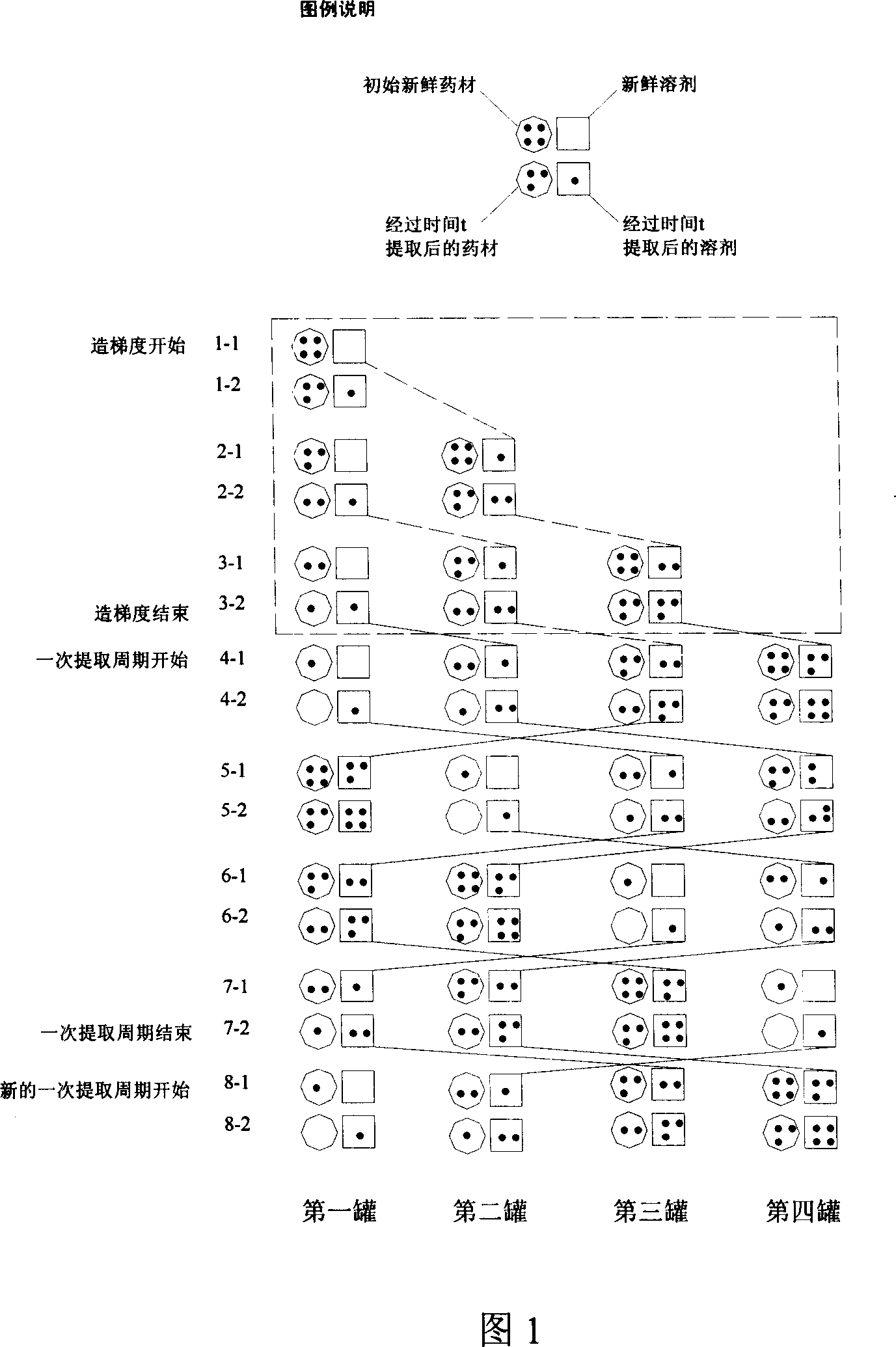

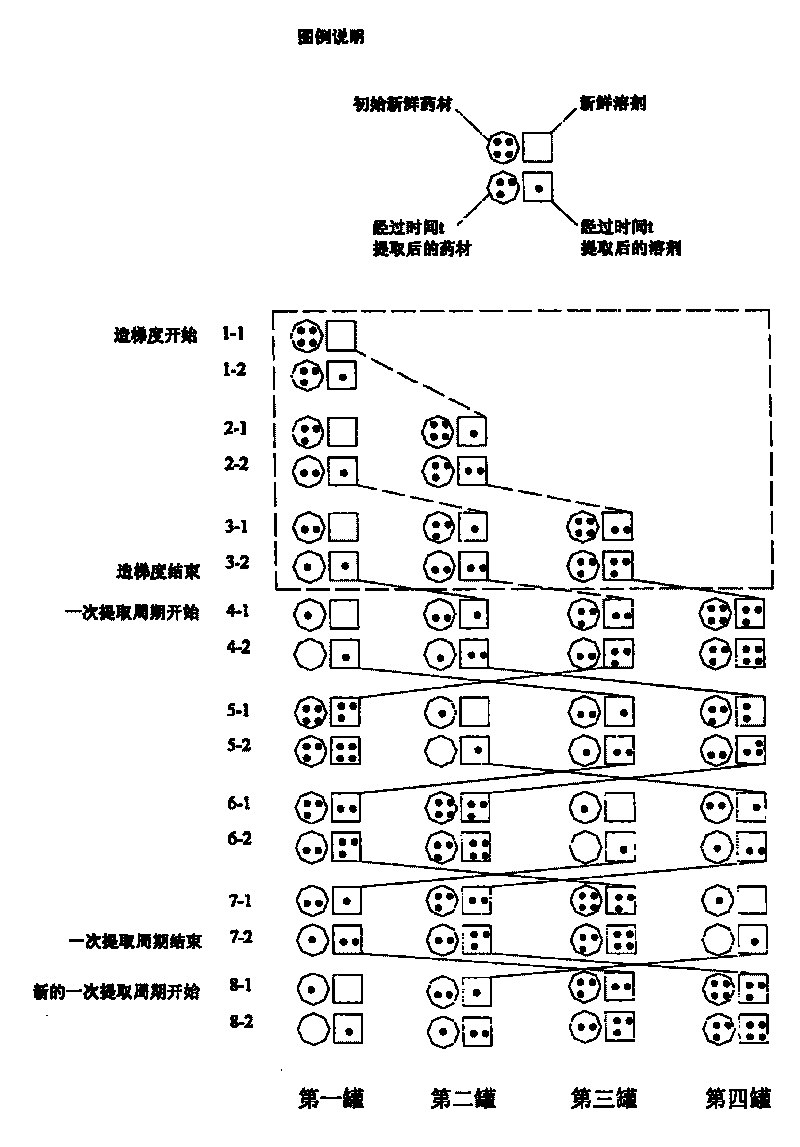

Extraction method of water soluble components from salvia miltiorrhiza by ultrasonic continuous countercurrent gradient

InactiveCN101007057ATo overcome the shortcoming of small concentration differenceImprove extraction efficiencyMetabolism disorderBlood disorderSalvia miltiorrhizaUltrasound - action

The invention disclosed a way to extract water soluble ingredient in danshen root with gradient hyper sound fortified successive countercurrent. After putting the jar with danshen root and solvents in hyper sound (the frequency is 40kHz and the power is 320-600W) for t, transferring the solvent to another jar with danshen root; putting new solvent into the first jar; extracting the two jars of danshen root at the same time and transferring the solvent one by one; successively countercurrent extracting the active ingredient in danshen root. Compared with the traditional hyper sound extracting method, the countercurrent extracting method in the invention can keep the density differences between the solid and liquid phase in a high level and decrease the solvents dosage so as to save the energy to condense, increase the extracting efficiency and increase the yield.

Owner:SOUTH CHINA UNIV OF TECH

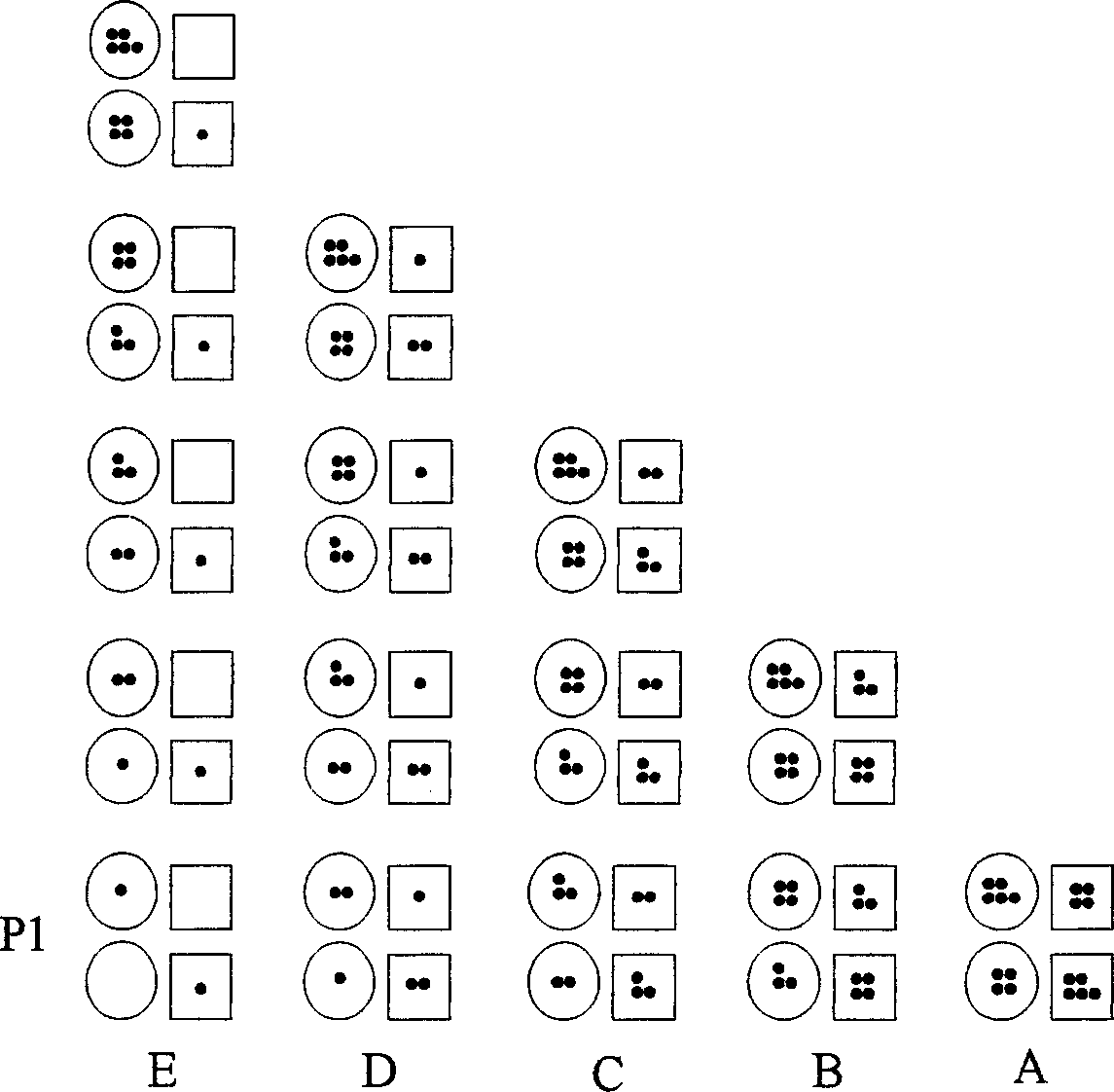

Giant knotweed rhizome active ingredient emodin extraction method

InactiveCN1800122AAbsolute reductionReduce consumptionHydrocarbon purification/separationHydrocarbonsAlcoholPOLYGONUM CUSPIDATUM

The invention provides a method for extracting the effective component archin of the giant knotweed rhizome, which puts the drugs into five extracting tanks after shattering them to in turn extract the E, D, C, B, A tank with the extracting solution: 30%-70% alcohol whose amount is 8-12 volume of the drug's quality, the temperature: 35-65 deg. and the time: 20-50 minutes, so that the effect component of the extracting solution of the five tanks descendent, it then discharges opeing the tank which has the highest effect component and discharges the dross of the tank which has been five solution extracted, it dose interval removal to the other extracting solution and dose four cycles and then amalgamates the extracting solutions.

Owner:ZHEJIANG UNIV

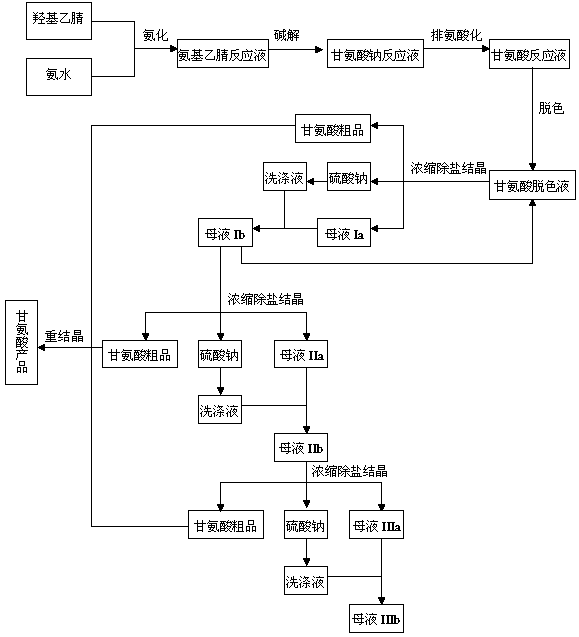

Preparation process of glycine

InactiveCN102432478BReduce pyrolysis polymerizationHigh yieldOrganic compound preparationAmino-carboxyl compound preparationReaction temperatureAlkaline hydrolysis

The invention discloses a preparation process of glycine, which comprises amination, alkaline hydrolysis, ammonia discharge acidification, decolorizing, concentration, desalting, crystallization and recrystallization steps, wherein in the amination step, hydroxyacetonitrile and ammonia water are mixed in a tubular reactor, and a reaction is undergone at the temperature of 50-100 DEG C under the pressure of 0.5-2.0 MPa for 4-10 minutes; and in the alkaline hydrolysis step, 30-50 percent of sodium hydroxide solution is added into an alkaline hydrolysis reactor in advance, an amination liquid is collected from an amination liquid outlet, a reaction is undergone at the temperature of 60-90 DEG C under the pressure of between -0.01 MPa and -0.09 MPa, and ammonia in a system is recovered simultaneously. In the process, the tubular reactor is taken as an amination reactor, so that the reaction temperature and pressure are raised, the reaction time is shortened, and raw material decomposition, pyrolytic polymerization of aminoacetonitrile and the generation of byproducts are reduced; alkaline hydrolysis is performed during the collection of the amination liquid, the concentration of an alkaline liquor and the alkaline hydrolysis temperature are raised simultaneously, and ammonia in the system is recovered under reduced pressure, so that the alkaline hydrolysis reaction is more complete, the speed is higher, and the generation of colored impurities is reduced; and a mother liquor circular utilizing mode is established, so that the treatment amount of waste mother liquor is reduced, the product yield is increased, and the production cost is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

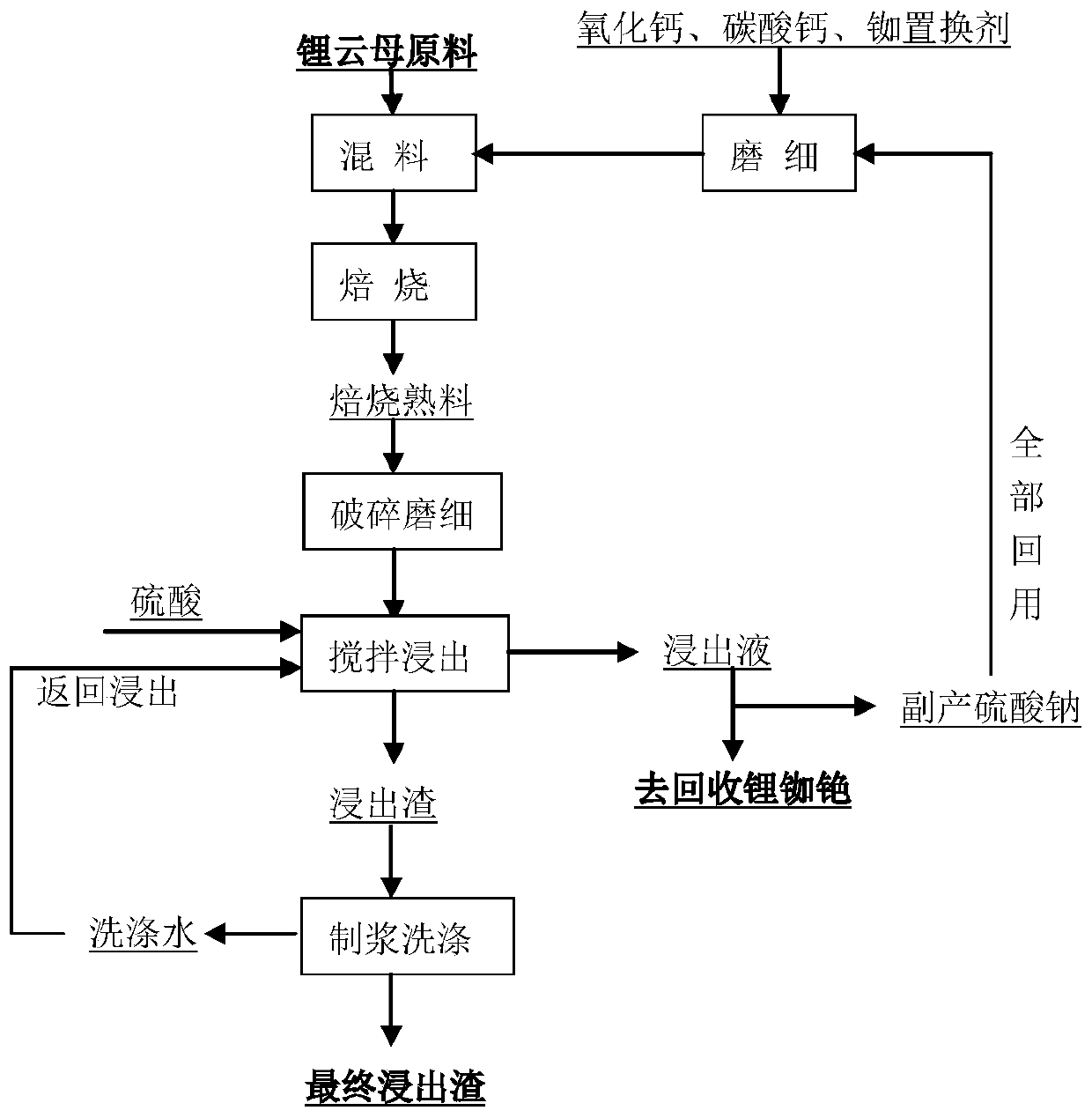

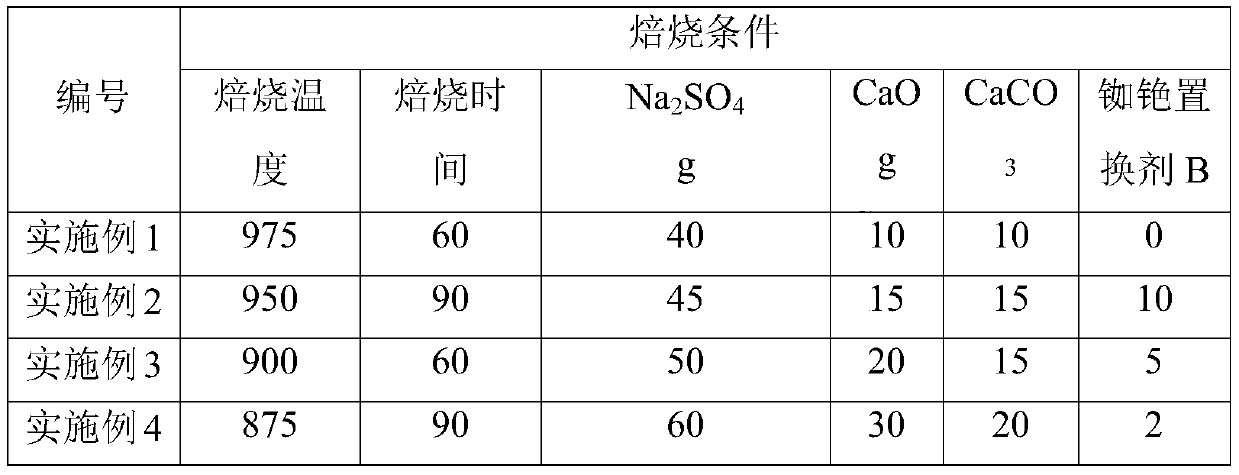

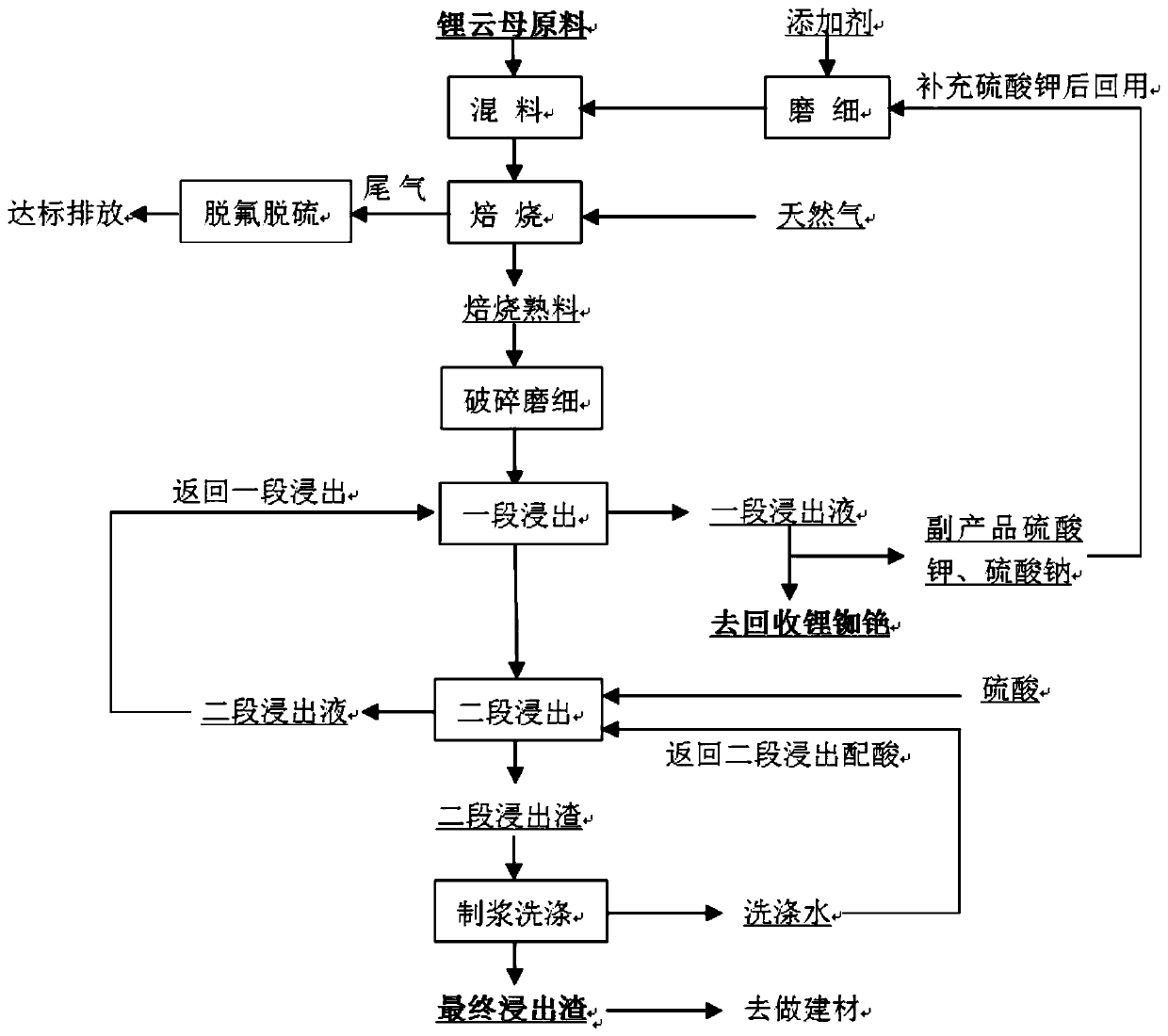

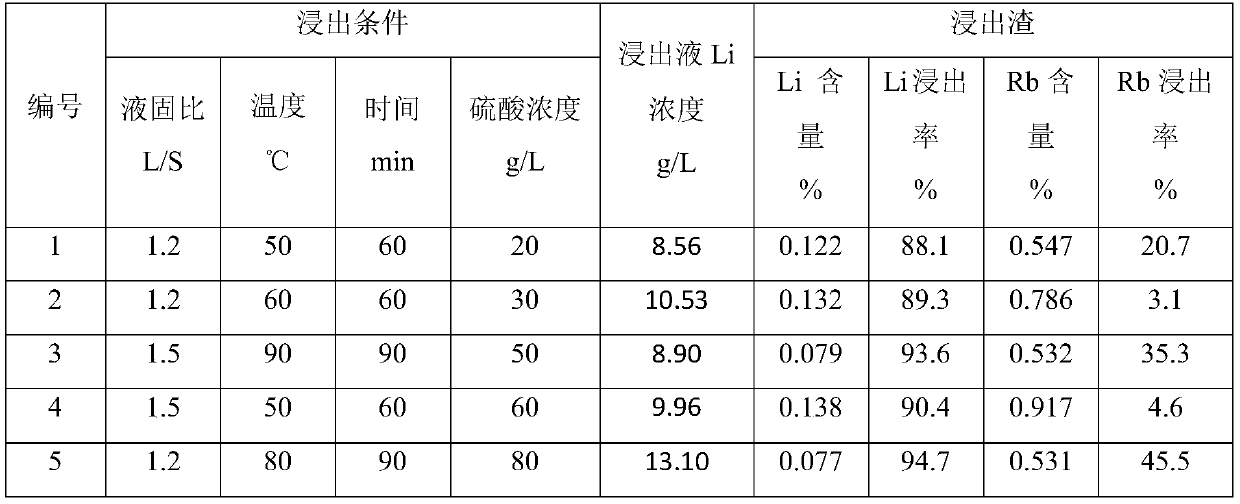

Lepidolite ore and sodium sulfate roasting and leaching method

InactiveCN110042225ALow cost of reagentsImprove sintering performanceProcess efficiency improvementLithium carbonateCalcium carbonate

The invention belongs to the technical field of extraction of lithium from ore, and particularly relates to lepidolite ore and sodium sulfate roasting and leaching method. The lepidolite ore and sodium sulfate roasting and leaching method comprises the following steps of: step (1). processing raw materials, and finely grinding sodium sulfate, calcium oxide, calcium carbonate and a rubidium and cesium displacer to a set degree; step (2). mixing, to be specific, uniformly mixing lepidolite concentrate powder with the sodium sulfate, the calcium oxide, the calcium carbonate and the rubidium and cesium displacer finely ground in the step (1) according to the set ratio; step (3). calcination, to be specific, calcining the above mixture at the temperature of 850 to 1000 DEG C to obtain a calcined clinker called calcine; step (4). finely grinding; step (5). transferring the finely ground calcine to a leaching tank, and leaching lithium and rubidium in the calcine; and step (6). mixing leaching residues with a set amount of water, stirring and washing at a set temperature, and washing out lithium, rubidium, and cesium in the leaching residues. According to the technical solution of the lepidolite ore and sodium sulfate roasting and leaching method, potassium sulfate is not used; and only single sodium sulfate is used, is a by-product of a lithium carbonate precipitation process, and does not need to be purchased, thus, the reagent cost is reduced, and the sulfate roasting technology has economical efficiency.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

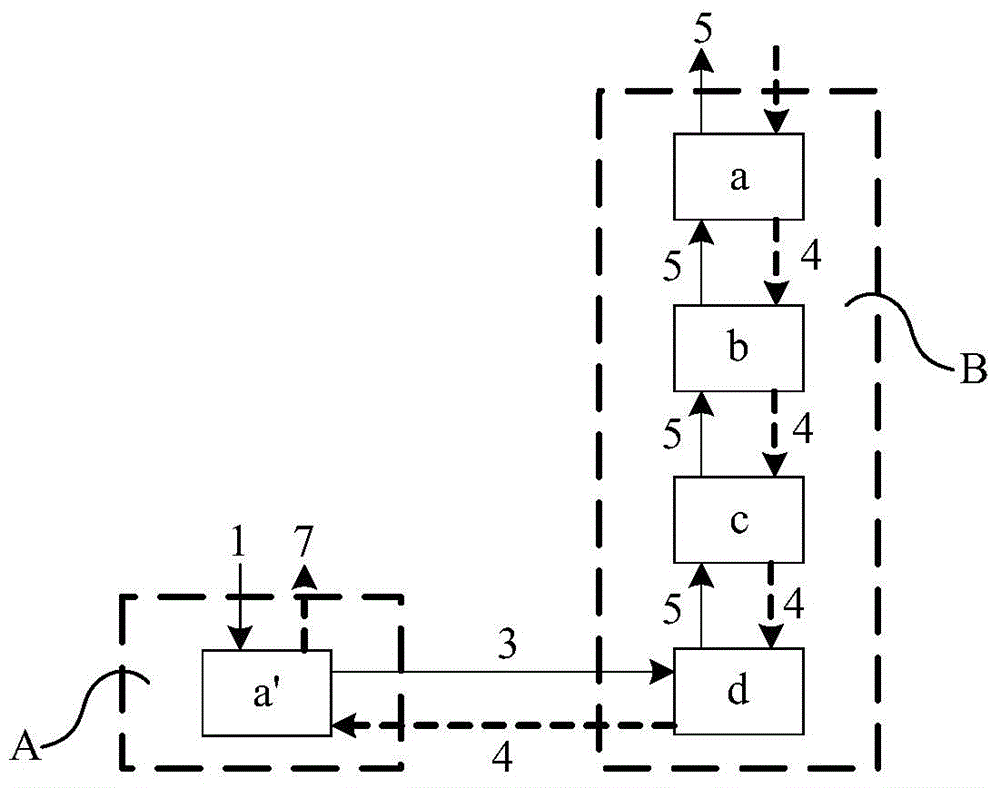

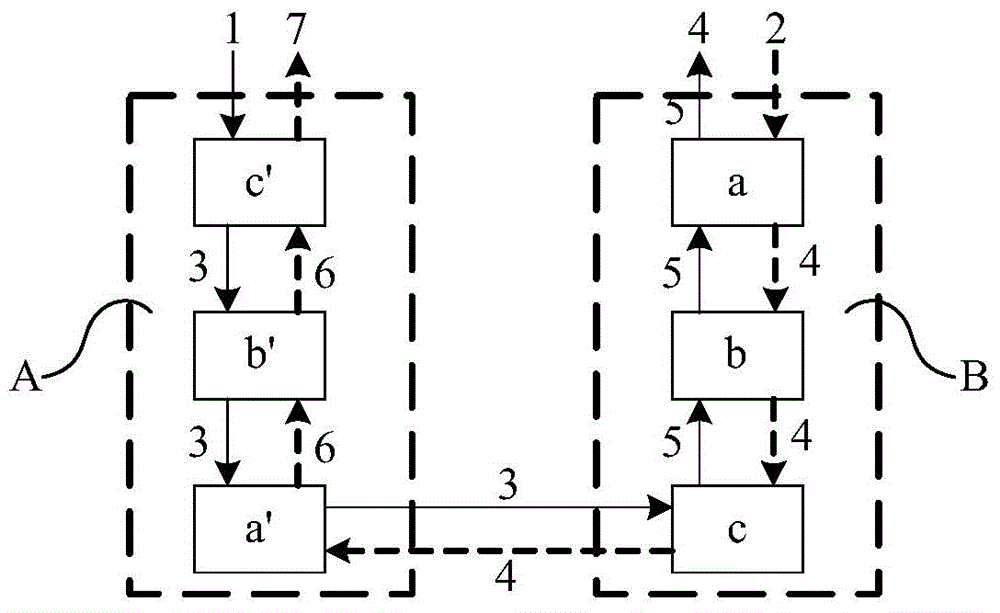

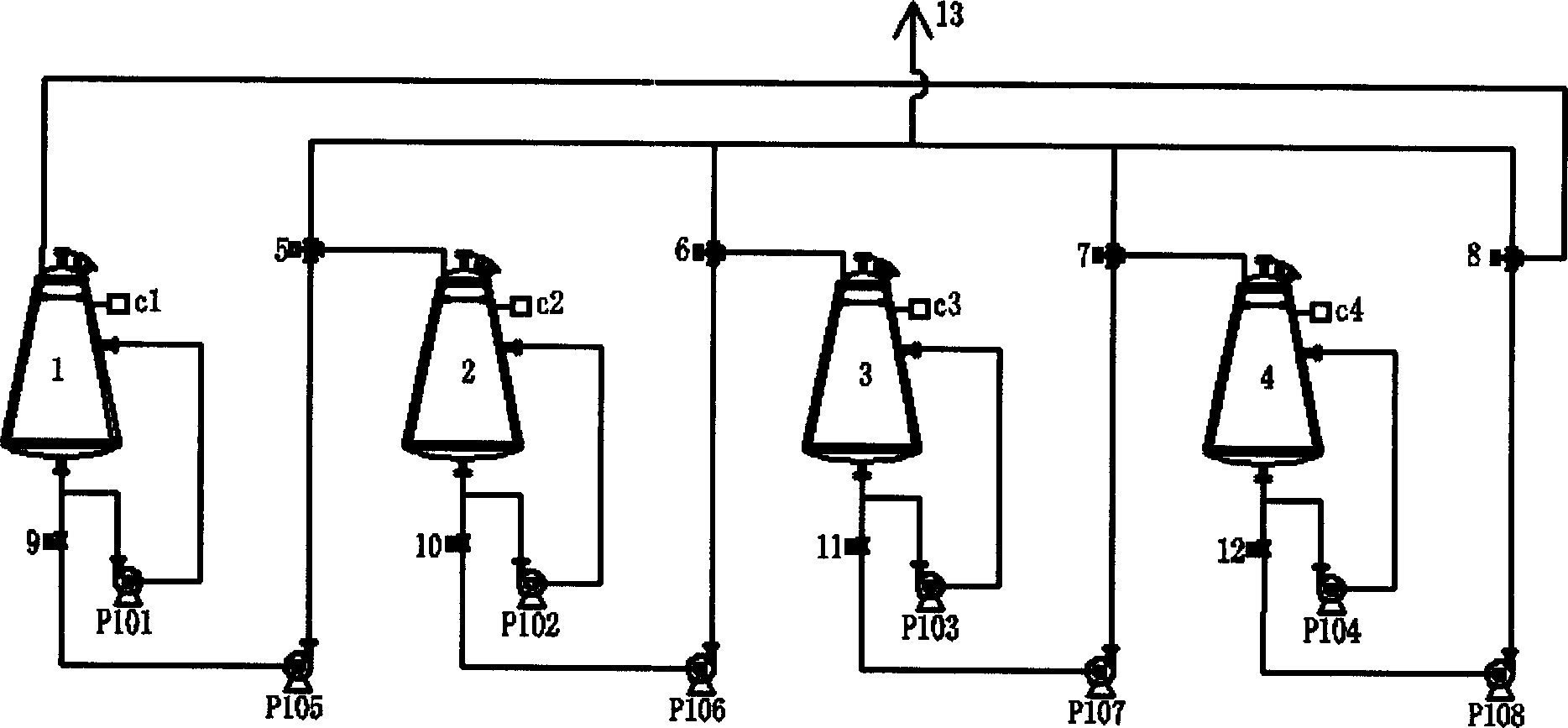

Continuous countercurrent extraction method using dynamic overflow and apparatus thereof

The invention relates to a method for extracting effective component of traditional Chinese medicine, with dynamic overflow continuous reverse-flow method, wherein said method uses several extractors, while each extractor works independently and they use active overflow method, to transfer liquid continuously. Compared with traditional method, the invention improves extracting speed, reduce solvent consumption, reduce following energy consumption and improve efficiency. The invention can reduce extracting temperature, etc. And the invention comprise several pots, heater, condenser, tubes, pump and value which control the active overflow between pots, and the meter element controlling the balance of whole device.

Owner:PHARM TECH TIANJIN

Centella total-glycoside diacolation-extracting method from centella

InactiveCN101455693AHigh extraction rateEasy to operateNervous disorderDigestive systemGlycoside formationSolvent

The invention discloses a method for extracting asiaticoside from asiatic centella comprising the step of using asiatic centella as raw material, and water solution of ethanol or methanol as extraction solvent for extracting asiaticoside from asiatic centella in high efficiency by percolation method for achieving more than 93% extraction ratio for the asiaticoside. The method has high extraction ratio, small consumption of solvent, low production cost, and easy commercial process.

Owner:ZHEJIANG UNIV

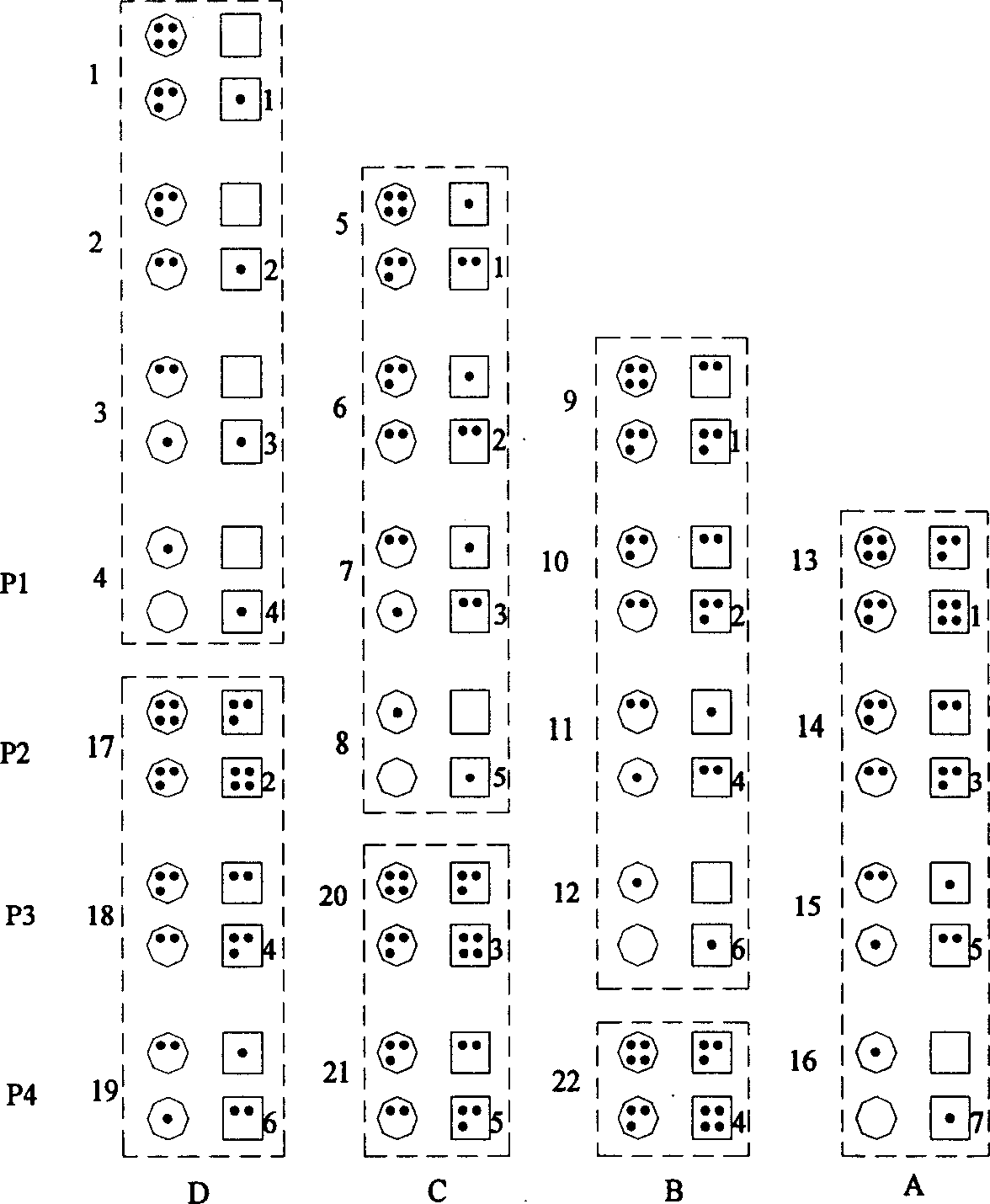

Method for extracting saponin active ingredient from pseudo-ginseng

The present invention discloses a method for extracting saponins effective component from Chinese medicinal material notoginseng. Said method adopts the following steps: firstly, pulverizing notoginseng root to obtain notoginseng powder whose grain size is 20-80 meshes, utilizing four extraction tanks of A,B,C and D, respectively adding 10g of notoginseng powder into every extraction tank, then adding 35%-90% ethyl alcohol solution into said four extraction tanks respectively, heating to 35-80deg.C and extracting for 20-60 min., successively making extraction of D,C.B and A to make effective component contents in extracts of four extraction tanks be successively decreased, then combining extracts. Said method can greatly raise extraction efficiency of notoginseng saponins effective component.

Owner:ZHEJIANG UNIV

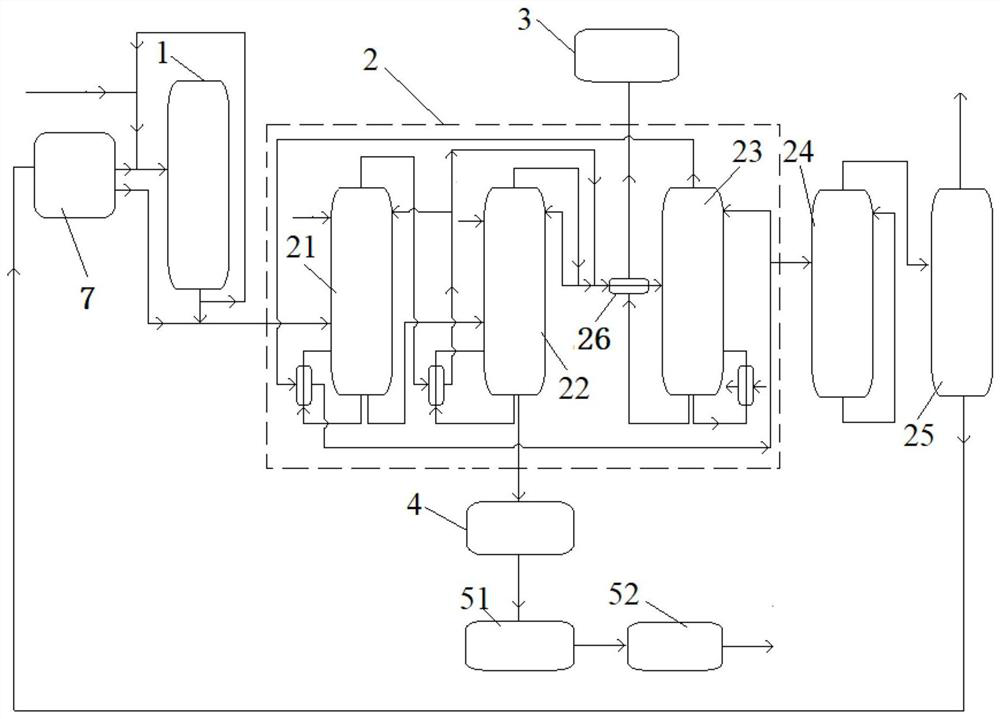

Treatment method of production wastewater of epoxypropane prepared by co-oxidation method

ActiveCN113003847AImprove biochemical propertiesReduce processing difficultyFatty/oily/floating substances removal devicesOrganic compound preparationCatalytic oxidationTower

The invention provides a treatment method of production wastewater of epoxypropane prepared by a co-oxidation method. The production wastewater comprises a first part of wastewater with peroxide content of 2000 mg / L or above and a second part of wastewater with peroxide content of less than 50 mg / L. The treatment method comprises the following steps: (1) carrying out catalytic oxidation on the first part of wastewater to obtain material wastewater; (2) mixing the discharged wastewater with a second part of wastewater, and rectifying through a first rectifying tower to obtain a first tower top material and primary concentrated wastewater as a first tower kettle liquid; rectifying the first tower bottoms through a second rectifying tower to obtain a second tower top material and secondary concentrated wastewater serving as second tower bottoms; performing oil-water separation on the first tower top material and the second tower top material through a third rectifying tower; (3) carrying out incineration treatment on the second tower bottoms; and (4) carrying out biochemical treatment on the third tower bottoms. The treatment method is suitable for high-salt, high-organic-matter-content and high-peroxide-content wastewater, peroxide in the wastewater can be removed, the biodegradability of the wastewater is improved, and the wastewater treatment difficulty and cost are reduced.

Owner:WANHUA CHEM GRP CO LTD

Method for increasing positive permeation performance by using ferric lactate complex as draw solution

ActiveCN106315766AReduce energy consumption for concentrationImprove performanceWater/sewage treatment bu osmosis/dialysisWaste minimisationPermeation

The invention provides a method for increasing positive permeation performance by using a ferric lactate complex as a draw solution, and belongs to the technical field of environmental pollution control engineering. The ferric lactate complex is prepared through a mild-condition one pot method, and the ferric lactate complex is applied to a positive permeation technology serving as the draw solution and is used for increasing the performance of the process. Due to structural characteristics of the ferric lactate complex, the ferric lactate complex prepared in the invention has higher water flux and lower reverse salt flux; meanwhile, the source of raw materials is wide, the cost is low, the preparation condition is mild, the toxicity is low, the membrane compatibility is good, and the recovery rate of the draw solution is higher, so that by using the ferric lactate complex as the draw solution, positive permeation can be effectively increased, and wider application of the positive permeation technology can be promoted through further study on the draw solution.

Owner:DALIAN UNIV OF TECH

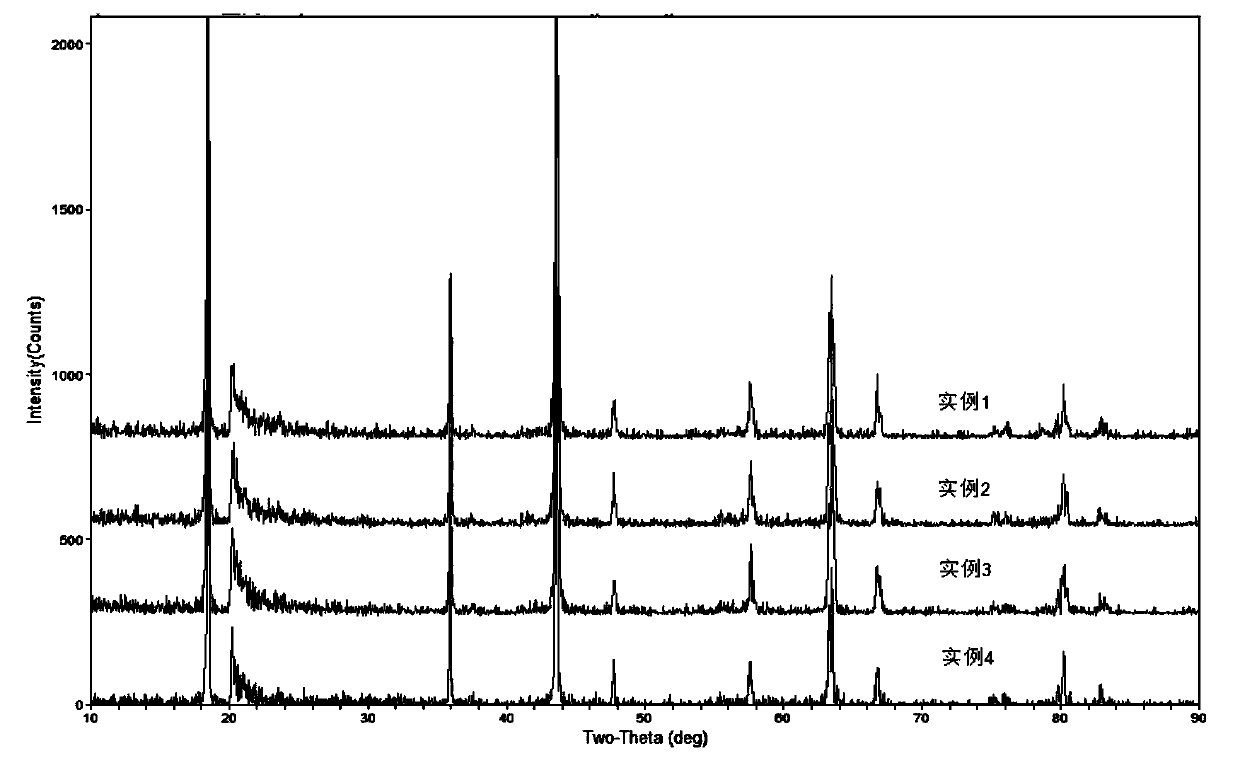

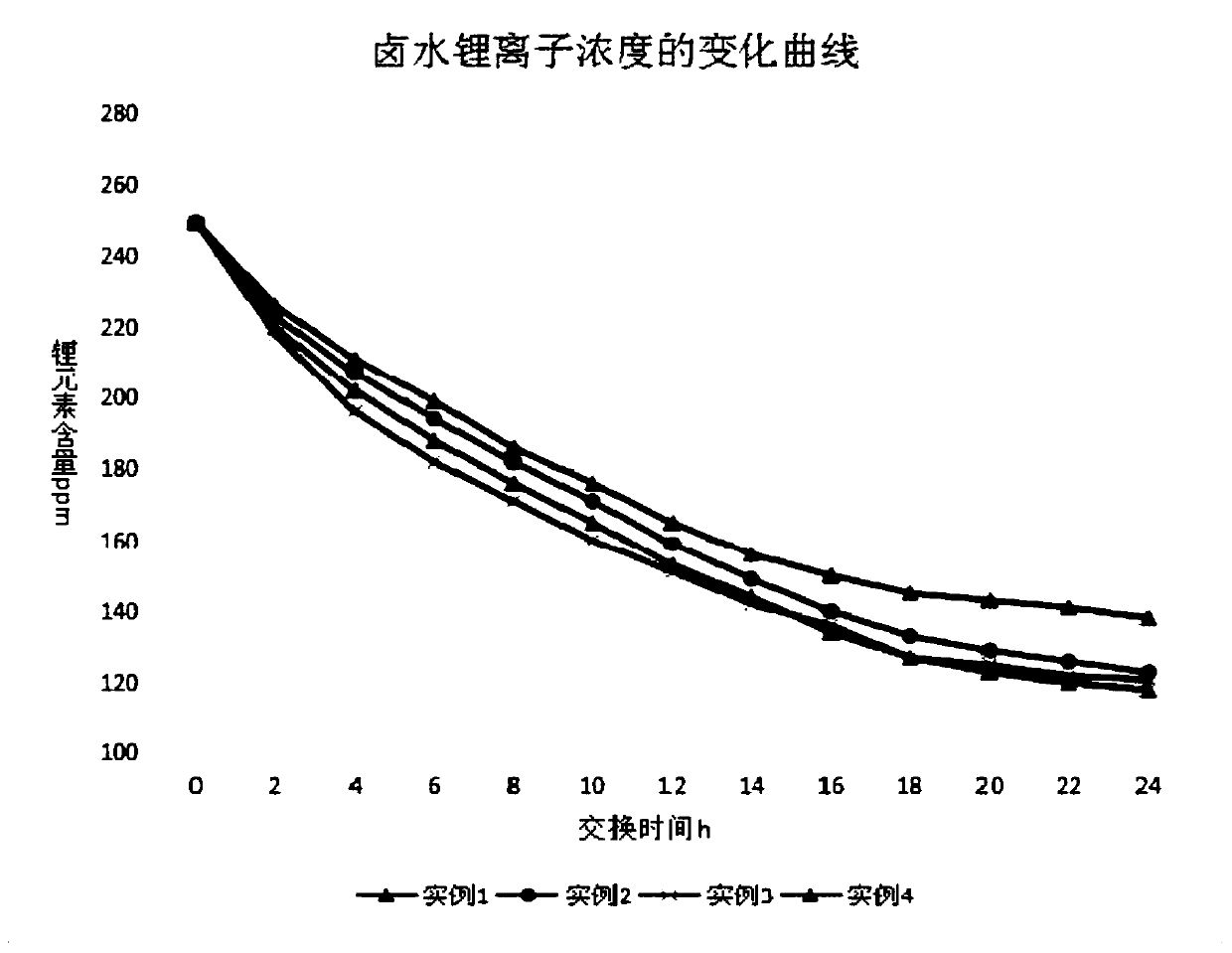

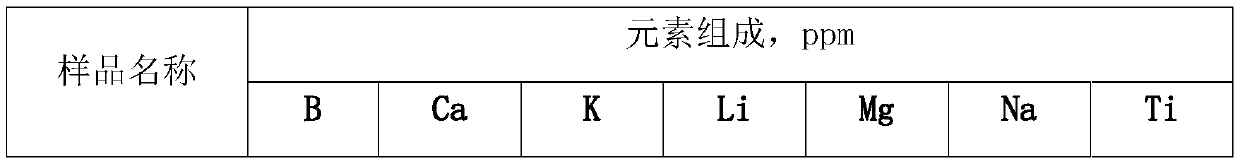

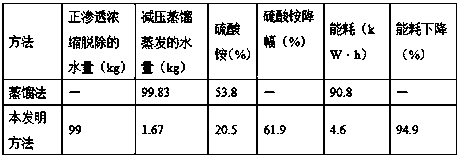

Preparation method of powder type high-capacity titanium-based lithium ion exchanger

InactiveCN110215935ASolve the situation where washing is difficultNo residueCation exchanger materialsWater contaminantsHigh concentrationProduction line

The invention provides a preparation method of a powder type high-capacity titanium-based lithium ion exchanger, wherein the titanium source is metatitanic acid on a sulfuric acid process production line, and the precursor can be prepared at low lithium source consumption and short calcination time. The lithium ion elution process of a precursor comprises stirring and adding acid to remove lithiumin a tank, that concentration of slurry H+ in the tank is controlled to prevent the dissolution of titanium, the dissolved lithium is concentrated in a solution, the solid and liquid are separated toobtain a lithium solution with high concentration and low acidity, the concentration energy consumption is reduced and alkali for neutralizing waste acid is reduced, thereby greatly reducing production cost.

Owner:JIANGSU TOP FINE NEW RAW MATERIAL CO LTD +1

Method for preparing nicotine sulfate

The invention relates to a method for preparing nicotine sulfate, and belongs to the technical field of tobacco chemistry. According to the method, an aquaporin membrane and a polyamide membrane are used as forward osmosis concentration membranes, an inorganic salt is used as an absorbing agent, and a low-concentration nicotine distillate is subjected to forward osmosis concentration until the trapped fluid nicotine concentration is 5%-20%; 5%-40% sulfuric acid which is slightly excessive in chemical calculation is added into a trapped fluid to obtain a nicotine sulfate solution with relatively high concentration, and then evaporating and concentrating are carried out to obtain a 40%-60% nicotine sulfate product. According to the method, the concentration of the reactant nicotine during nicotine sulfate generation is greatly improved by adopting forward osmosis concentration, so that the concentration of the reaction product nicotine sulfate is improved, the evaporation capacity of water during preparation of a final product by subsequent evaporation and concentration is reduced, and the evaporation energy consumption is greatly reduced; by utilizing the characteristic of poor interception efficiency of forward osmosis concentration on ammonia, the ammonia content in the trapped liquid is greatly reduced, so that the ammonium salt content in a final product is greatly reduced,and the purity of nicotine sulfate is greatly improved.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

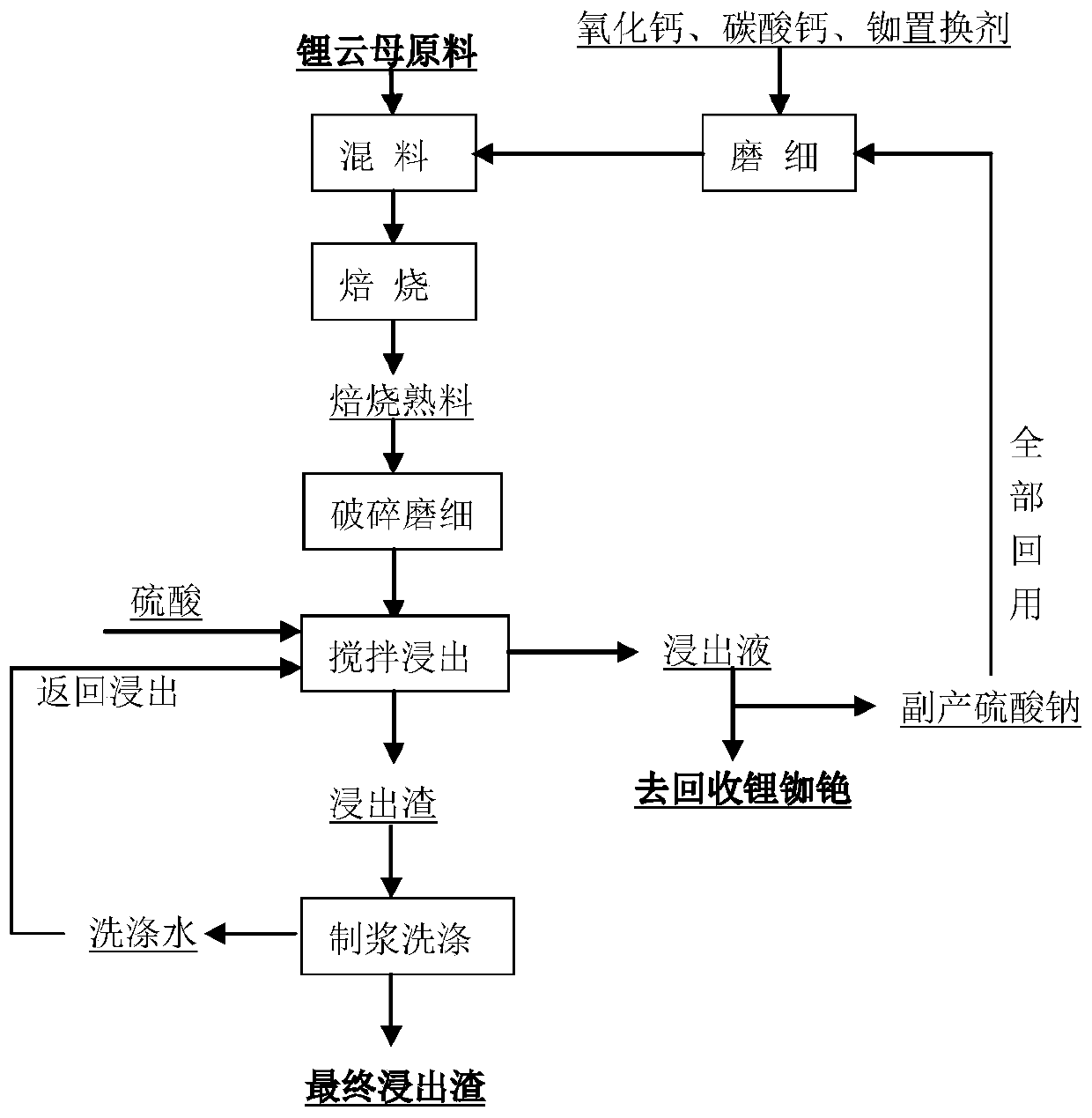

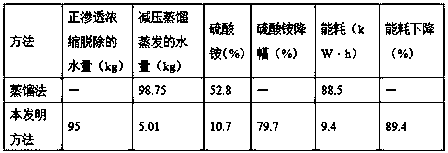

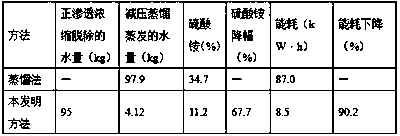

Pretreatment and leaching method of lepidolite

InactiveCN109929993AEasy to handleLess fluorine escapeProcess efficiency improvementLepidoliteMaterials science

The invention relates to the technical field of extracting lithium from ores, and particularly discloses a pretreatment and leaching method of lepidolite. The method comprises the first step of grinding of a reagent, the second step of mixing, the third step of roasting, the fourth step of crushing and grinding, the fifth step of one-stage leaching, the sixth step of two-stage leaching and the seventh step of pulping and washing. The method is economical and high in operability and has the industrial application value, calcium oxide and calcium carbonate are added during roasting to play a role of fixing fluorine, the sintering performance of the calcine can be improved, and calcine is loose and fragile.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

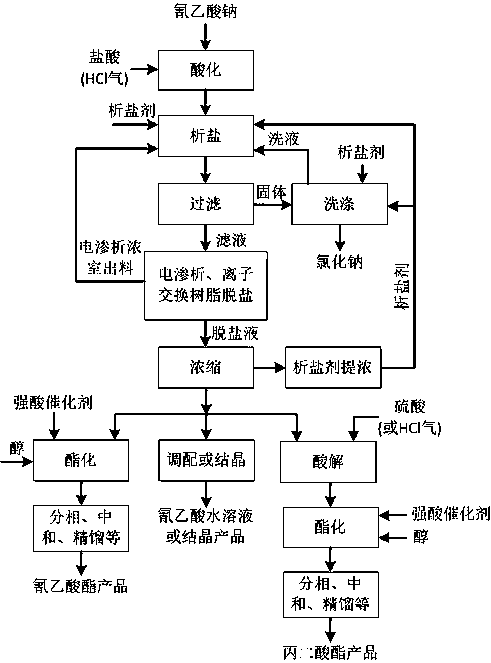

Environment-friendly clean production method of high-purity cyanoacetic acid, cyanoacetate and malonate

InactiveCN111393323AReduce investmentEasy to operateOrganic compound preparationCarboxylic acid esters preparationEnvironmental chemistryMalonate

The invention discloses an environment-friendly clean production method of high-purity cyanoacetic acid, cyanoacetate and malonate. The method comprises the following steps: carrying out an acidification reaction on sodium cyanoacetate and hydrochloric acid or HCl gas to obtain an acidified solution, carrying out salt precipitation by using a salt precipitation agent, filtering to obtain a filtrate, carrying out electrodialysis and other desalination treatments to obtain a desalted solution, concentrating the desalted solution, and crystallizing to prepare high-purity cyanoacetic acid, or esterifying to prepare cyanoacetate, or carrying out acidolysis and esterification to prepare malonate. According to the method, cyanoacetic acid and sodium chloride are well separated by desalting methods such as electrodialysis after salt precipitation; and the problems of cyanoacetic acid decomposition caused by concentration separation of cyanoacetic acid and salt and sulfuric acid consumption andmixed salt wastewater treatment caused by residual sodium chloride during esterification in the prior art are avoided, so that the method is the environment-friendly and clean production method.

Owner:高春燕

Method for concentrating horizontal-flow primary sedimentation tank sludge

ActiveCN104891608AReduce bound water contentReduce difficultySludge treatment by de-watering/drying/thickeningWater/sewage treatmentIron powderSludge

The invention relates to the technical field of sludge dehydrating treatment, and especially relates to a method for concentrating horizontal-flow primary sedimentation tank sludge. sewage is sent to a horizontal-flow primary sedimentation tank, iron powder and powdered carbon are added in the horizontal-flow primary sedimentation tank, iron powder and powdered carbon form microelectrolysis in the horizontal-flow primary sedimentation tank, sewage is mixed with iron powder and powdered carbon and stirred for stirring processing, the iron powder is uniformly mixed with the powdered carbon in the horizontal-flow primary sedimentation tank, microbattery formed by the iron powder and powdered carbon can be distributed on the whole primary sedimentation tank, the organic matter in the sludge and microbe cell wall can be degraded or ruptured under effect of microelectrolysis, extruding processing of a gantry crane grab bucket is combined, so that color substance in sewage can be removed, water in the microbe cell wall in the sludge can be dissociated, combination water content in the sludge is reduced, sludge condensation processing difficulty is reduced, sludge dehydration rate is increased, press filtration load and difficulty of a filter press are reduced, and sludge processing cost is reduced.

Owner:GUIZHOU ANKAIDA IND

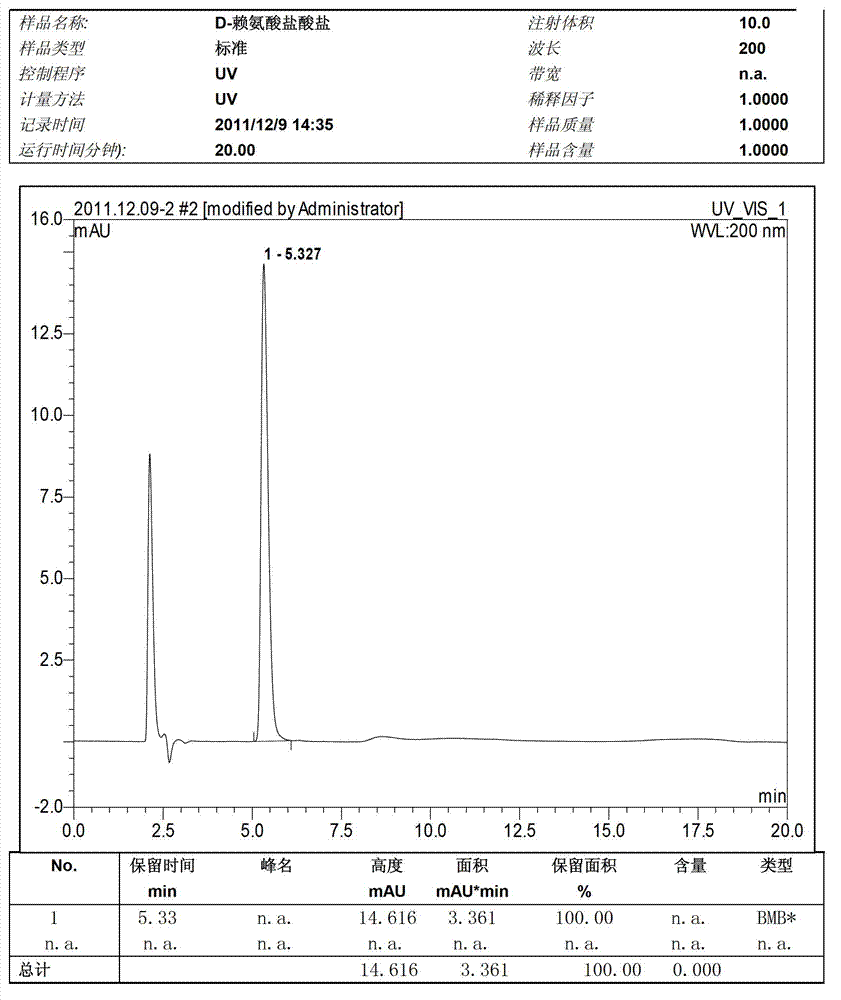

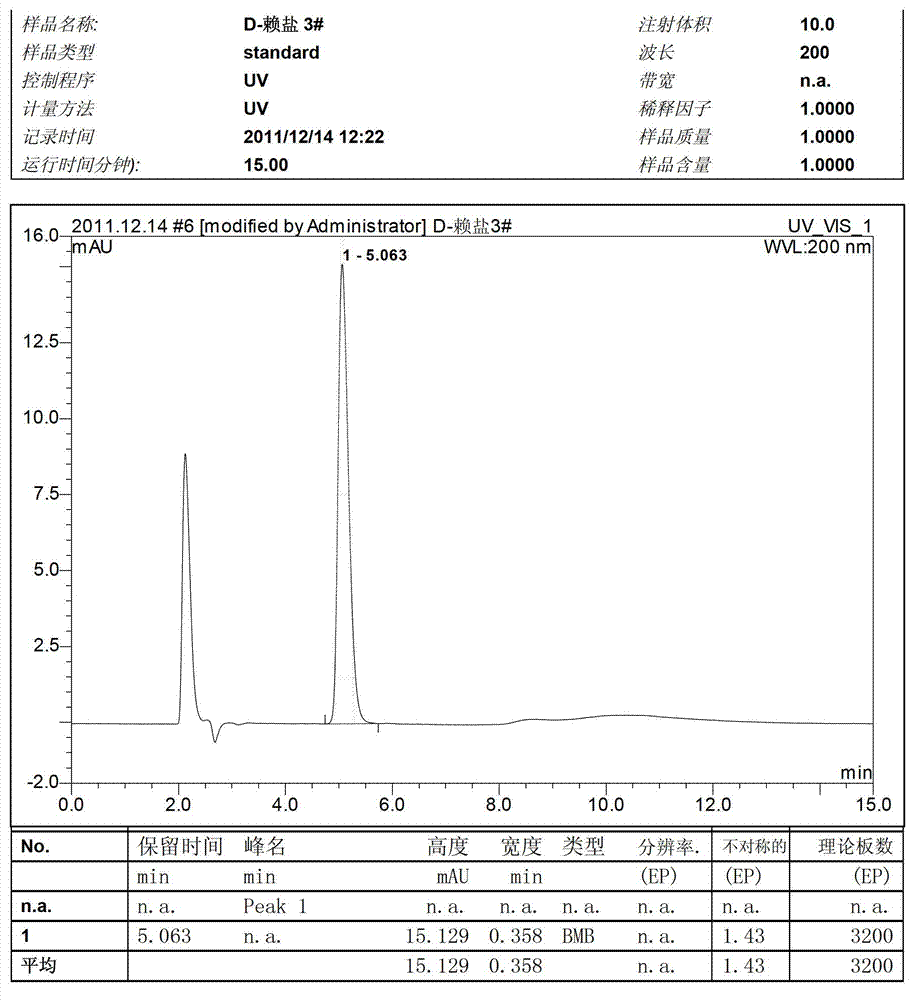

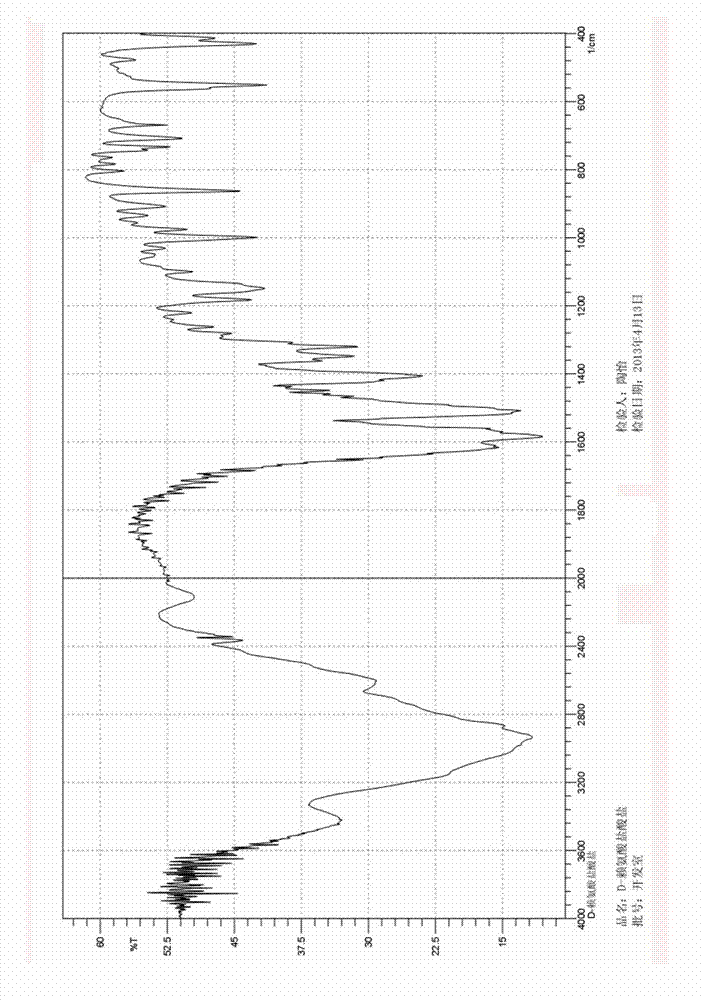

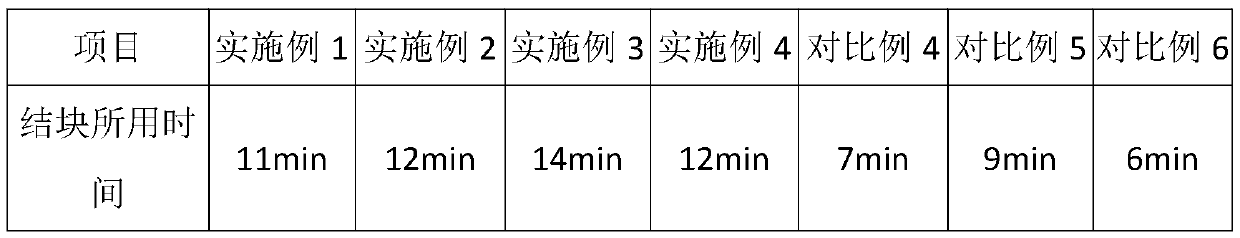

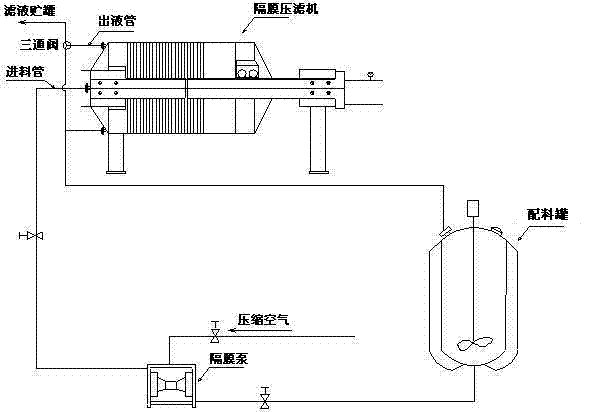

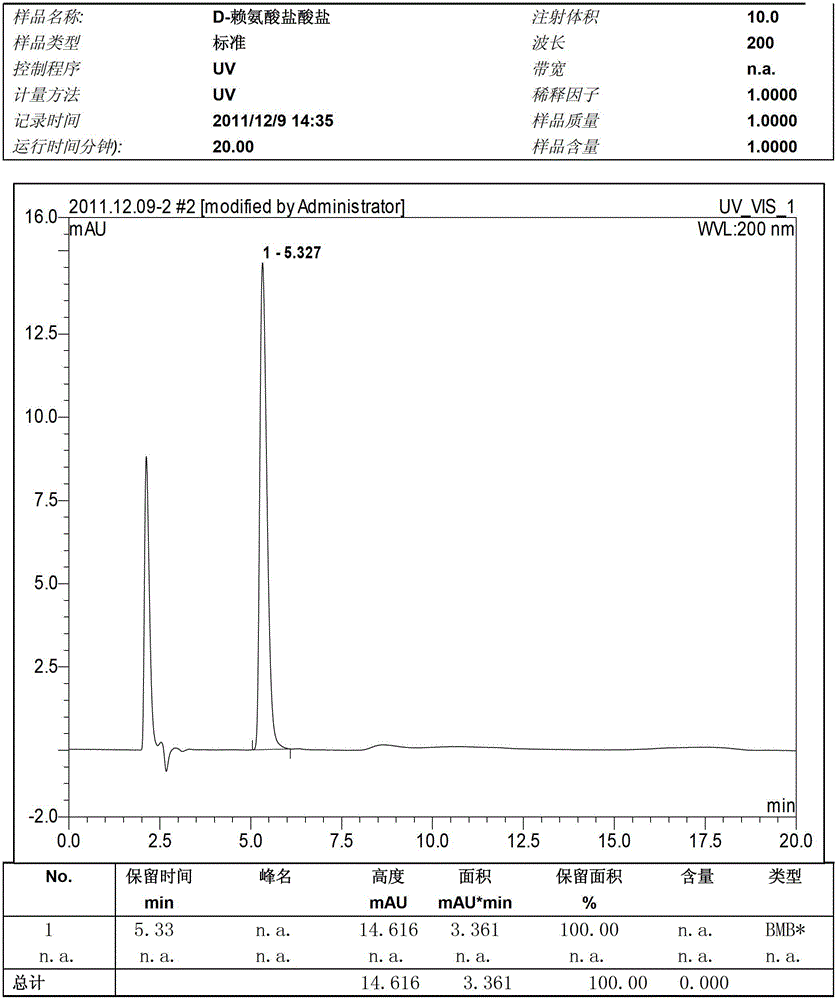

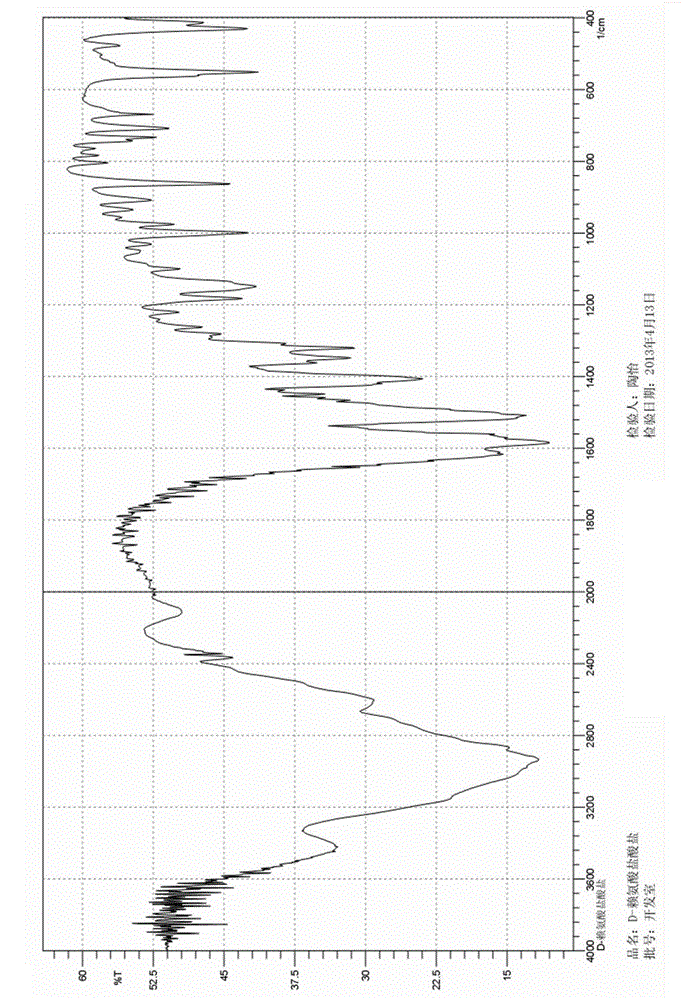

Preparation method of D-lysine hydrochloride

InactiveCN103204783AEasy to separateLow priceOrganic compound preparationAmino-carboxyl compound preparationIon exchangeCalcium tartrate

The invention relates to a preparation method of D-lysine hydrochloride. The method comprises the following steps of: by taking DL-lysine as a raw material, after purification, reacting at 30-70 DEG C with L-tartaric acid to generate diastereomer salt; then, performing inorganic calcium salt with diastereomer salt to generate a calcium tartrate precipitate, while maintaining D-lysine in a liquid; adjusting pH, decoloring, concentrating and crystallizing the D-lysine liquid through hydrochloric acid to obtain D-lysine hydrochloride crude crystalline; and purifying the D-lysine hydrochloride crude crystalline to obtain the D-lysine hydrochloride. The content of DL-lysine in the D-lysine hydrochloride is below 0.5%. According to the method provided by the invention, a simple neutralization precipitation method replaces a complex ion-exchange resin method to the benefit of simplifying the production method and stabilizing the product quality. Meanwhile, the method further has the advantages of no special devices and reduction of environmental pollution, and is easy to popularize and apply industrially.

Owner:ZHANGJIAGANG HUACHANG PHARMA

Extraction method of water soluble components from salvia miltiorrhiza by ultrasonic continuous countercurrent gradient

InactiveCN101007057BTo overcome the shortcoming of small concentration differenceImprove extraction efficiencyMetabolism disorderBlood disorderSalvia miltiorrhizaUltrasound - action

The invention disclosed a way to extract water soluble ingredient in danshen root with gradient hyper sound fortified successive countercurrent. After putting the jar with danshen root and solvents inhyper sound (the frequency is 40kHz and the power is 320-600W) for t, transferring the solvent to another jar with danshen root; putting new solvent into the first jar; extracting the two jars of danshen root at the same time and transferring the solvent one by one; successively countercurrent extracting the active ingredient in danshen root. Compared with the traditional hyper sound extracting method, the countercurrent extracting method in the invention can keep the density differences between the solid and liquid phase in a high level and decrease the solvents dosage so as to save the energy to condense, increase the extracting efficiency and increase the yield.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of sodium chlorate

The invention belongs to the field of chemical industry, and particularly relates to a preparation method of sodium chlorate. The preparation method of sodium chlorate comprises the following steps: firstly dissolving sodium chloride into water to obtain a saturated sodium chloride solution, then carrying out filtering, carrying out diluting, and carrying out electrolyzing to obtain a crude sodiumchlorate solution; adding an ionic chelating agent into the crude sodium chlorate solution, carrying out standing, and carrying out centrifuging to obtain a purified sodium chlorate solution A; adding a hydrochloric acid solution, and removing bromine, chlorate radicals and free chlorine in a bromine removal tower to obtain a purified sodium chlorate solution B; adding sodium hydroxide for neutralizing, carrying out concentrating to obtain a concentrated sodium chlorate solution, finally adding an anti-caking agent, and carrying out crystallizing to obtain sodium chlorate. According to the method, the ionic chelating agent is added in the process of preparing sodium chlorate to remove metal ions in the solution, so that purity of the obtained sodium chlorate is higher; the efficient anti-caking agent is added, so that the defect that sodium chlorate is easily caked in a placing process is overcome, and quality of the sodium chlorate is remarkably improved; and ultrasonic concentrationis adopted, so that energy is saved.

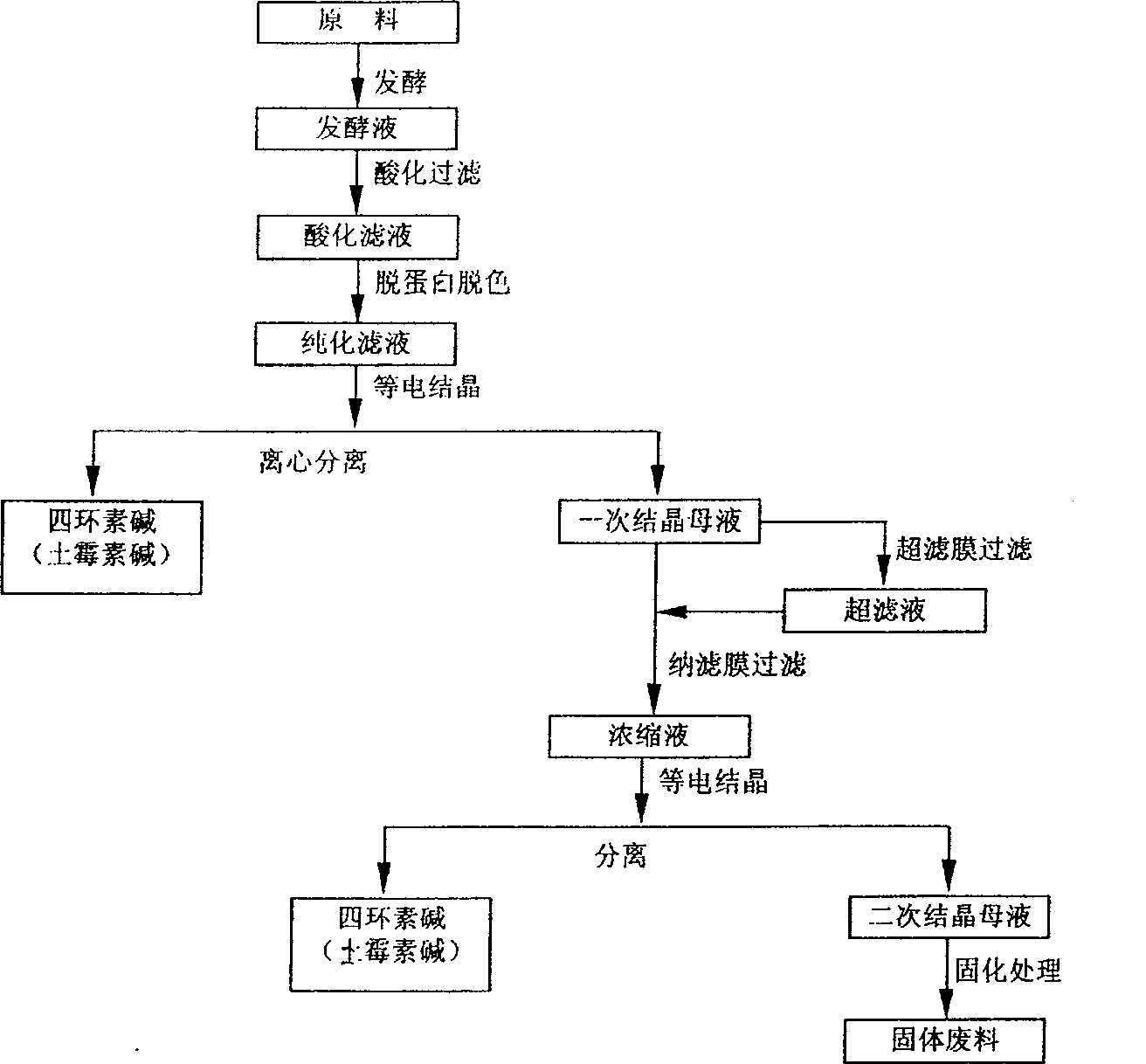

Clean production process of tetracycline antibiotics

InactiveCN100487129CIncrease recycling processSolve pollutionCarboxylic acid amide separation/purificationFermentationTetracycline antibioticsAntibiotics

The improved clean production process of tetracycline antibiotics has the steps of concentrating and separating the first crystallized mother liquid to obtain concentrated solution; electrically crystallizing the concentrated solution and separating to obtain product while leaving the second crystallized mother liquid; concentrating and drying the second crystallized mother liquid to form solid waste; etc. The improved process recovers tetracycline antibiotics from the first crystallized mother liquid and solidifies the second crystallized mother liquid so as to raise tetracycline antibiotics yield and reduce environment protecting job.

Owner:凯能高科技工程(上海)有限公司

A kind of tobacco extract concentration process

ActiveCN109499369BLow operating pressureImprove securityUltrafiltrationElectrodialysisNicotiana tabacumBiology

The invention relates to a process for concentrating tobacco extract, belonging to the technical field of concentrating tobacco extract. The process is to micro-filter the tobacco water extract after primary purification, carry out forward osmosis concentration on the microfiltration permeate, and recover and recycle the diluted drawing solution formed by the forward osmosis concentration by electrodialysis or drying salt. The process of the invention has low operating pressure and high safety; the concentration temperature is low, the temperature rise is small during concentration, and heat exchange and temperature reduction are not required; the membrane pollution is light, the cleaning is simple and the cleaning frequency is low. At the same time, the process of the present invention has a high degree of concentration, and the concentration of the tobacco extract after concentration can reach 60%; in the process of concentrating the tobacco extract of reconstituted tobacco leaves in the papermaking method, it can completely replace evaporation and concentration; and the loss of materials, nicotine and volatile components in the process of concentration Small, low energy consumption, easy to popularize and apply.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

A method for thickening sludge in a convection flow primary sedimentation tank

ActiveCN104891608BReduce bound water contentReduce difficultySludge treatment by de-watering/drying/thickeningWater/sewage treatmentIron powderFiltration

The invention relates to the technical field of sludge dehydrating treatment, and especially relates to a method for concentrating horizontal-flow primary sedimentation tank sludge. sewage is sent to a horizontal-flow primary sedimentation tank, iron powder and powdered carbon are added in the horizontal-flow primary sedimentation tank, iron powder and powdered carbon form microelectrolysis in the horizontal-flow primary sedimentation tank, sewage is mixed with iron powder and powdered carbon and stirred for stirring processing, the iron powder is uniformly mixed with the powdered carbon in the horizontal-flow primary sedimentation tank, microbattery formed by the iron powder and powdered carbon can be distributed on the whole primary sedimentation tank, the organic matter in the sludge and microbe cell wall can be degraded or ruptured under effect of microelectrolysis, extruding processing of a gantry crane grab bucket is combined, so that color substance in sewage can be removed, water in the microbe cell wall in the sludge can be dissociated, combination water content in the sludge is reduced, sludge condensation processing difficulty is reduced, sludge dehydration rate is increased, press filtration load and difficulty of a filter press are reduced, and sludge processing cost is reduced.

Owner:GUIZHOU ANKAIDA IND

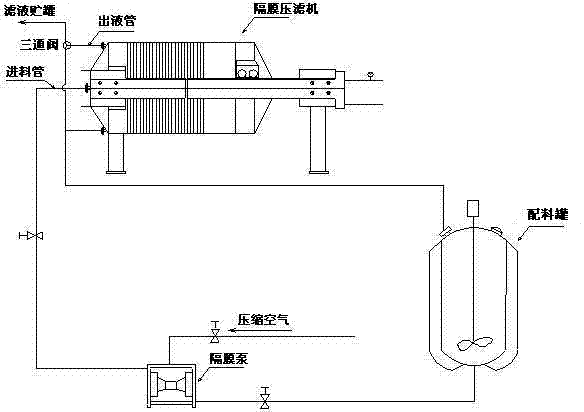

Preparation method of traditional Chinese medicine composition for treating infection of upper respiratory tract

ActiveCN102293826BHigh recovery rateIncrease contentRespiratory disorderPlant ingredientsMedicinal herbsBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a traditional Chinese medicine composition for treating infection of the upper respiratory tract. In the invention, a diaphragm press filtration cycle extraction and separation integrative technology is adopted to replace a boiling method to be utilized for extraction of medicinal material active ingredients. Therefore, the preparation method simplifies a process flow, shortens a production period, reduces energy consumption, is beneficial for environmental protection and waste dreg utilization, and improves greatly a recovery rate of active ingredients.

Owner:TAIJI GRP CHONGQING FULING PHARM FACTORY CO LTD

Preparation method of anti-diarrheal medicinal composition

ActiveCN102293884BHigh recovery rateIncrease contentDigestive systemPlant ingredientsMedicinal herbsProcess engineering

Owner:TAIJI GRP CHONGQING FULING PHARM FACTORY CO LTD

A kind of preparation method of d-lysine hydrochloride

InactiveCN103204783BEasy to separateLow priceOrganic compound preparationAmino-carboxyl compound preparationIon exchangeCalcium tartrate

The invention relates to a preparation method of D-lysine hydrochloride. The method comprises the following steps of: by taking DL-lysine as a raw material, after purification, reacting at 30-70 DEG C with L-tartaric acid to generate diastereomer salt; then, performing inorganic calcium salt with diastereomer salt to generate a calcium tartrate precipitate, while maintaining D-lysine in a liquid; adjusting pH, decoloring, concentrating and crystallizing the D-lysine liquid through hydrochloric acid to obtain D-lysine hydrochloride crude crystalline; and purifying the D-lysine hydrochloride crude crystalline to obtain the D-lysine hydrochloride. The content of DL-lysine in the D-lysine hydrochloride is below 0.5%. According to the method provided by the invention, a simple neutralization precipitation method replaces a complex ion-exchange resin method to the benefit of simplifying the production method and stabilizing the product quality. Meanwhile, the method further has the advantages of no special devices and reduction of environmental pollution, and is easy to popularize and apply industrially.

Owner:ZHANGJIAGANG HUACHANG PHARMA

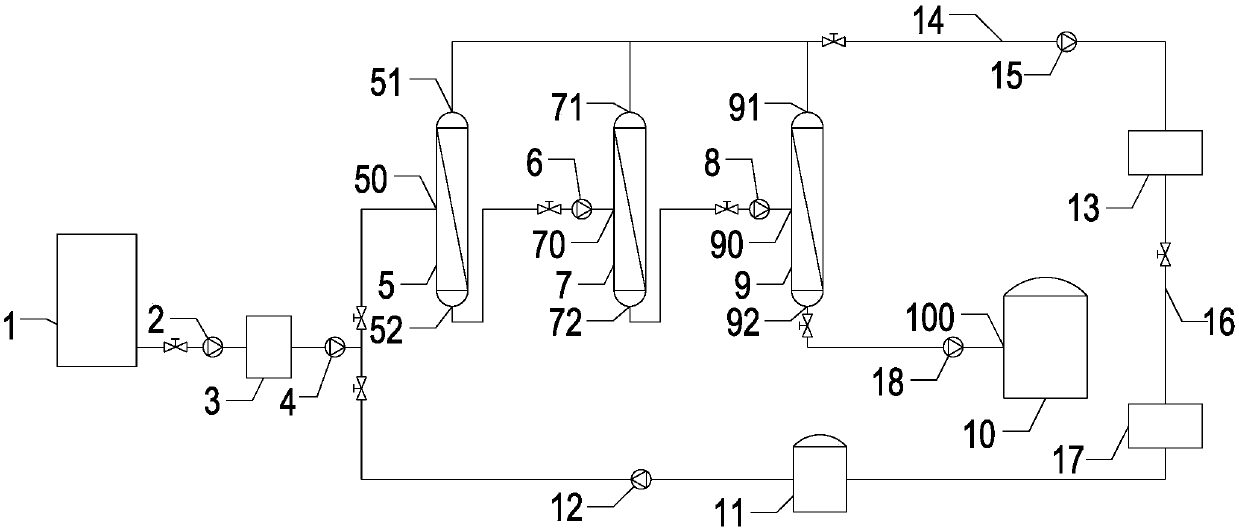

Fruit juice membrane concentration system

InactiveCN110583928AHigh separation precisionReduce energy consumption for concentrationFood scienceFruit juiceEvaporation

The invention provides a fruit juice membrane concentration system. The fruit juice membrane concentration system comprises a raw material storing jar, a first pump, a filtering sieve, a second pump,an ultrafiltration jar, a third pump, a nanofiltratoin jar, a fourth pump, a concentration jar, a concentrated solution storing jar, a clean water storing jar, an evaporator and a buffer jar. When thefruit juice membrane concentration system works, fruit juice is subjected to purification treatment sequentially through the filtering sieve, the ultrafiltration jar, the nanofiltratoin jar and the concentration jar of the fruit juice membrane concentration system, the fruit juice after purification treatment is inputted in the concentrated solution storing jar, so that the situation that the separation precision of the fruit juice is high can be guaranteed, and the concentration energy consumption of the fruit juice is reduced; in addition, the clean water storing jar is connected with the inlet of the ultrafiltration jar, so that the cleaning of the fruit juice membrane concentration system can be realized in an on-line manner; and the evaporator and the buffer jar which are connected with the clean water storing jar can perform evaporation and condensation on filter liquor of the concentration jar, the nanofiltratoin jar and the ultrafiltration jar to obtain clean water, and the clean water is poured into the clean water storing jar, so that the cyclic utilization of the filter liquor is realized.

Owner:广州市果美味食品有限公司

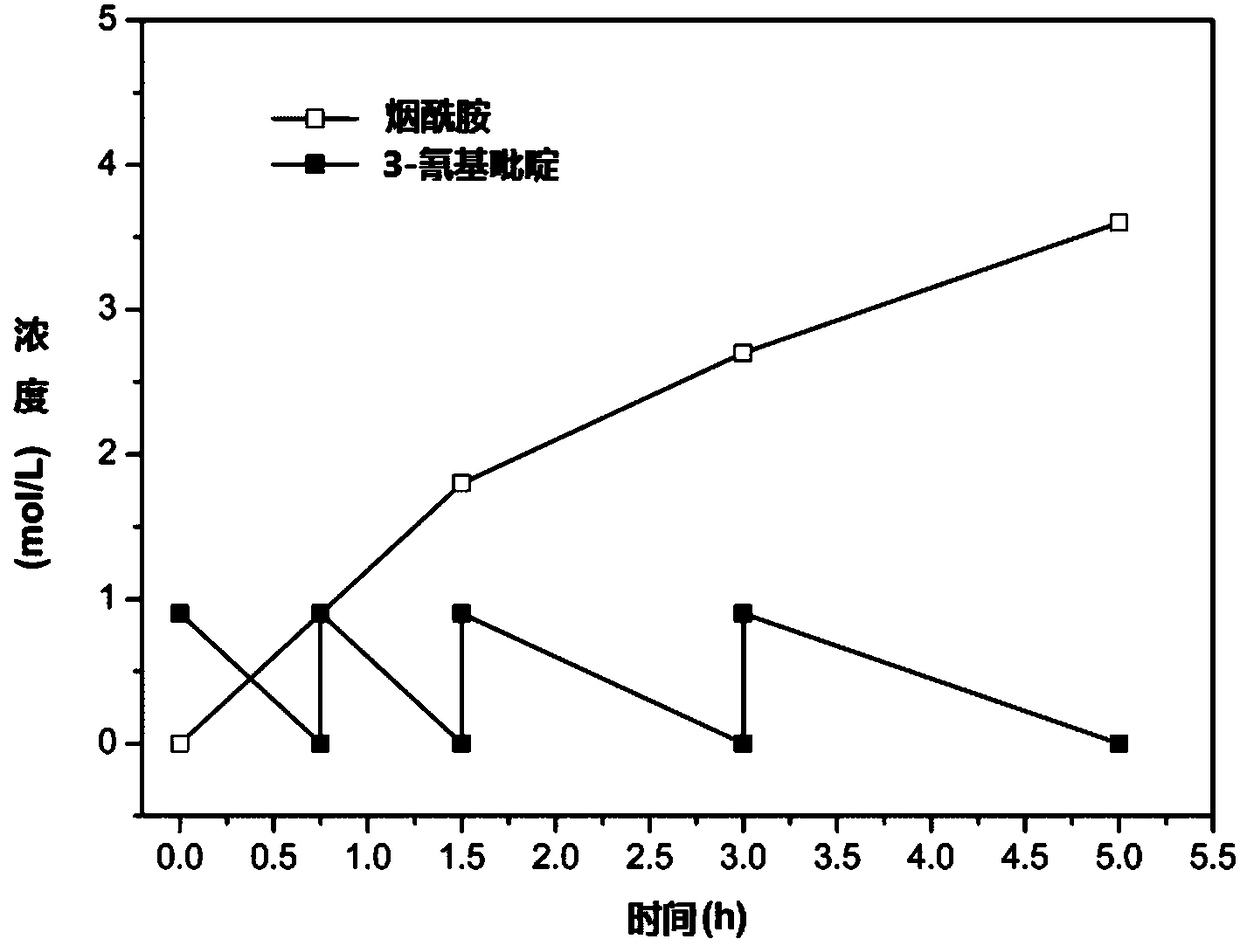

A kind of production technology of nicotinamide

ActiveCN107916283BImprove qualityEfficient amidation reactionMicroorganism based processesFermentationEscherichia coliHydration reaction

The invention discloses a preparation technology of niacinamide. The preparation technology comprises the following steps of building of gene engineering bacteria, fermenting culture of engineering bacteria, and performing catalytic reaction, wherein the engineering bacteria comprise escherichia coli host cells and a nitrile hydratase gene of which the base sequence is shown in SEQ ID NO.1 or SEQID NO.2; in the catalyzing process, pure water is used as a reaction medium to prepare a cell suspension liquid; 3-cyanopyridine is added into the cell suspension liquid by batches, and the concentration of the 3-cyanopyridine in the reaction system is controlled to be 90g / L or less, so as to obtain the niacinamide. The preparation technology has the advantages that the gene engineering bacteria containing the recombinant nitrile hydratase with high enzyme activity is used for fermenting culture, the pure water is used as the reaction medium, and the 3-cyanopyridine is added into the cell suspension liquid in a batched base matter adding way, so as to perform the hydration reaction at high efficiency, thereby obtaining the niacinamide product; the conversion rate of the hydration reactionis more than 99.9%, the quality of the obtained product is high, and the impurities and byproducts are not produced.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com