Treatment method of production wastewater of epoxypropane prepared by co-oxidation method

A treatment method, propylene oxide technology, applied in the direction of special compound water treatment, biological water/sewage treatment, water/sewage treatment, etc., can solve the problem of no relatively mature system process, low peroxide removal efficiency, and production unit consumption increase and other issues, to achieve the effect of improving process safety, saving construction and operating costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

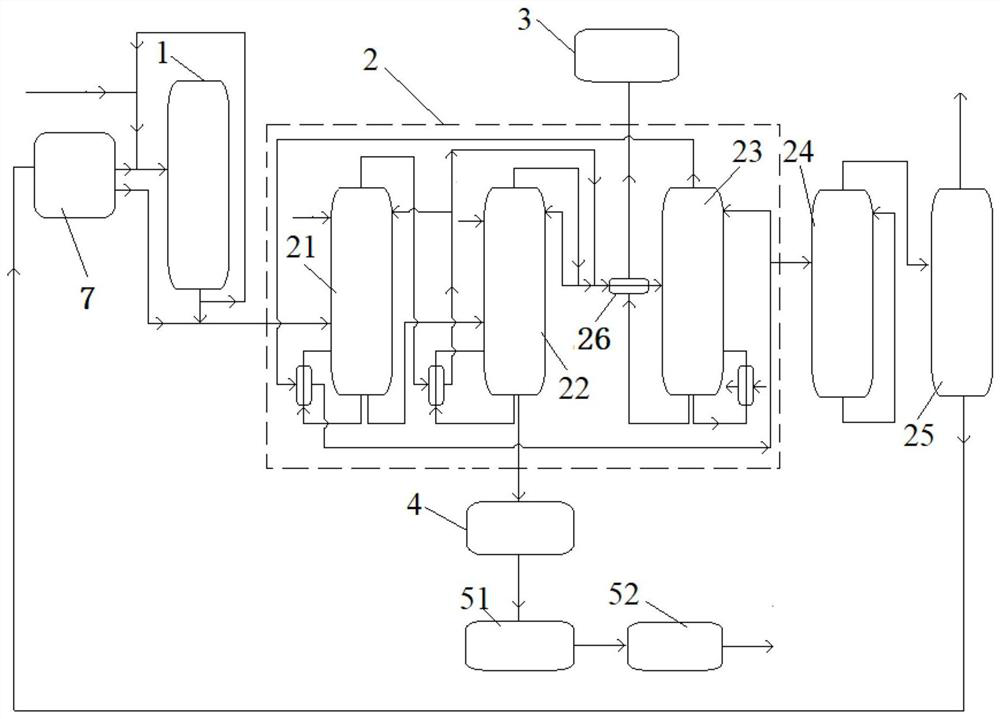

[0064] Such as figure 1 Shown, a kind of co-oxidation method prepares the processing method of propylene oxide production waste water as follows:

[0065] (1) The first part of waste water is sent to the catalytic oxidation reactor 1 in advance to carry out the catalytic oxidation reaction, to remove the peroxide therein, obtain the discharge waste water from the outlet of the catalytic oxidation reactor 1; Part of the discharge waste water of the device 1 is circulated into the catalytic oxidation reactor 1 from its feed port; an alkaline solution is added to the discharge waste water of the circulation part, so that the alkaline solution is mixed with the discharge of the circulation part. The waste water is transported into the catalytic oxidation reactor 1 to increase the pH of the material system therein;

[0066] (2) The mixed wastewater obtained after mixing the discharged wastewater with the second part of wastewater is input to the first rectification tower 21 in the...

Embodiment 2

[0092] Processing method is identical with embodiment 1;

[0093] The processing conditions are as follows:

[0094] The co-oxidation method for preparing propylene oxide system 7 is a POSM system from Yantai Wanhua Industrial Park. In the waste water produced by it, in the first part of waste water, the content of peroxide is 28000mg / L, and the COD is 100000mg / L ; In the second part of waste water, the peroxide content is 45mg / L;

[0095] The catalyst used in the catalytic oxidation reaction is MnO 2 / NiO composite catalyst, MnO 2 The mass ratio of NiO to NiO is 2:1; the temperature of the catalytic oxidation reaction is 70°C, and the feed space velocity is 2h -1 , the resulting discharge waste water after decomposition by catalytic oxidation reaction, its circulation ratio is 1.5; the alkaline solution that this part of circulation discharge waste water is input is NaOH solution, and concentration is 25wt%, and its addition makes described catalytic oxidation reactor The p...

Embodiment 3

[0108] Processing method is identical with embodiment 1;

[0109] The processing conditions are as follows:

[0110] The system 7 for preparing propylene oxide by the co-oxidation method is a POSM system from Yantai Wanhua Industrial Park. In the waste water produced by it, in the first part of waste water, the content of peroxide is 20000mg / L, and the COD is 10000mg / L ; In the second part of waste water, the peroxide content is 30mg / L;

[0111] The catalyst used in the catalytic oxidation reaction is MnO 2 / NiO composite catalyst, MnO 2 The mass ratio of NiO to NiO is 1:1; the temperature of the catalytic oxidation reaction is 20°C, and the feed space velocity is 4h -1 , the discharge waste water gained after catalytic oxidation reaction decomposition, its circulation ratio is 1.5; The alkaline solution that this part of circulation discharge waste water is input is NaOH solution, and concentration is 20wt%, and its addition makes described catalytic oxidation reactor The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com