Pre-treatment process of imidacloprid wastewater

A technology of imidacloprid and pretreatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problem of large dilution ratio of biochemical influent water, high requirements for reaction conditions and high treatment costs. problems, to achieve the effect of saving dosage, good effect and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

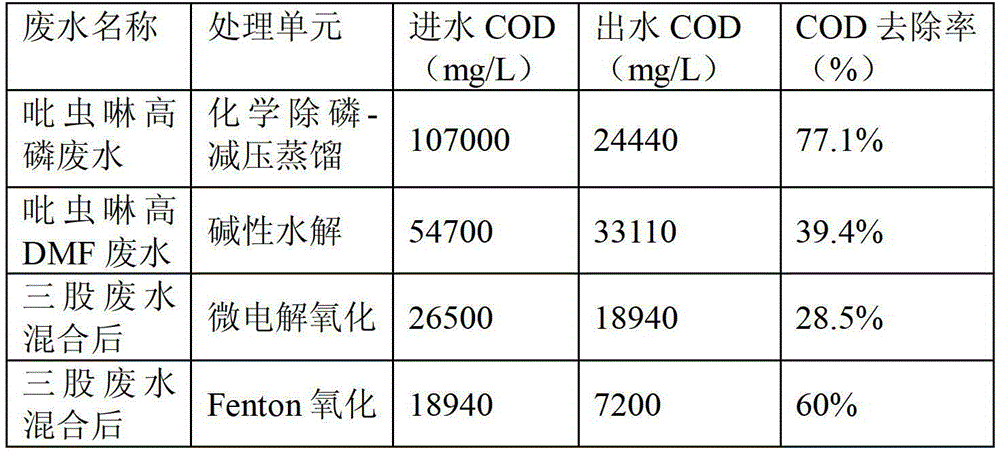

[0026] Wastewater from imidacloprid production of a pesticide manufacturer in Yancheng:

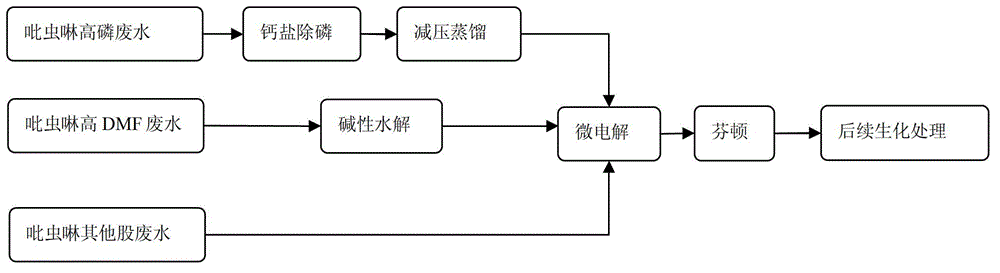

[0027] (1) The imidacloprid production wastewater is divided into three streams according to the production process, which are imidacloprid high phosphorus wastewater, imidacloprid high DMF wastewater, and imidacloprid other stream wastewater. First add calcium carbonate 90g / L to the high phosphorus wastewater. Then add milk of lime to adjust the pH to 7, after static precipitation, take the supernatant. Use hydrochloric acid to adjust the pH of the waste water to 5, adjust the vacuum degree, and carry out distillation at a pressure of 0.03 MPa to obtain the distilled liquid. At this time, COD dropped from 107000mg / L of influent to 24440mg / L.

[0028] (2) Use milk of lime to adjust the pH of high DMF wastewater to 11. After alkaline hydrolysis in a 60-degree water bath for 2 hours, the COD is from 54700mg / L to 33110mg / L.

[0029] (3) After mixing the wastewater treated in (1) and (2) w...

Embodiment 2

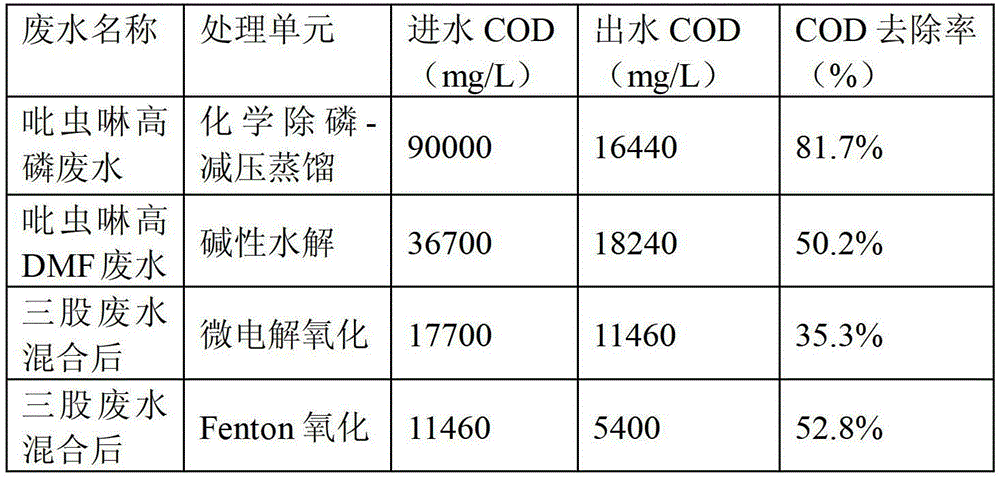

[0034] Wastewater from imidacloprid production of a pesticide manufacturer in Yangzhou:

[0035] (1) Divide imidacloprid production wastewater into three streams according to the production process, one stream is high-phosphorus wastewater, and 80 g / L of calcium carbonate is added to the high-phosphorus wastewater first. Then add milk of lime to adjust the pH to 8, after static precipitation, take the supernatant. Use hydrochloric acid to adjust the pH of the waste water to 6, adjust the vacuum degree, and carry out distillation at a vacuum degree of 0.04MPa to obtain the distilled liquid. At this time, COD dropped from 90000mg / L of influent to 16440mg / L.

[0036] (2) Use stone caustic soda to adjust the pH of high-DMF wastewater to 12, and after 3.5 hours of alkaline hydrolysis in a 70-degree water bath, the COD of the influent is from 36700 mg / L to 18240 mg / L.

[0037] (3) After mixing the wastewater treated in (1) and (2) with the remaining wastewater, adjust the pH to 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com