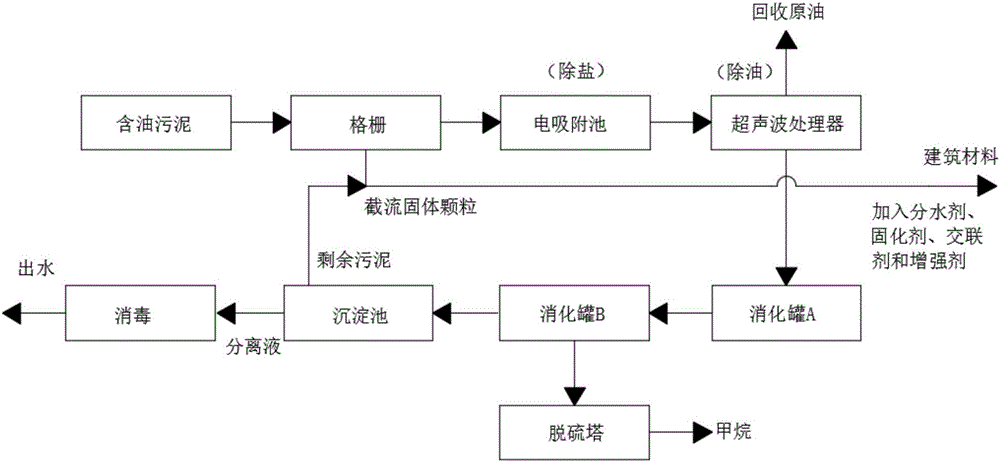

Oil field drilling sludge treatment and comprehensive utilization method

A technology for sludge treatment and oilfield drilling, applied in the fields of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of environmental pollution, low calorific value, and few practical applications, so as to increase production and improve biochemical performance. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

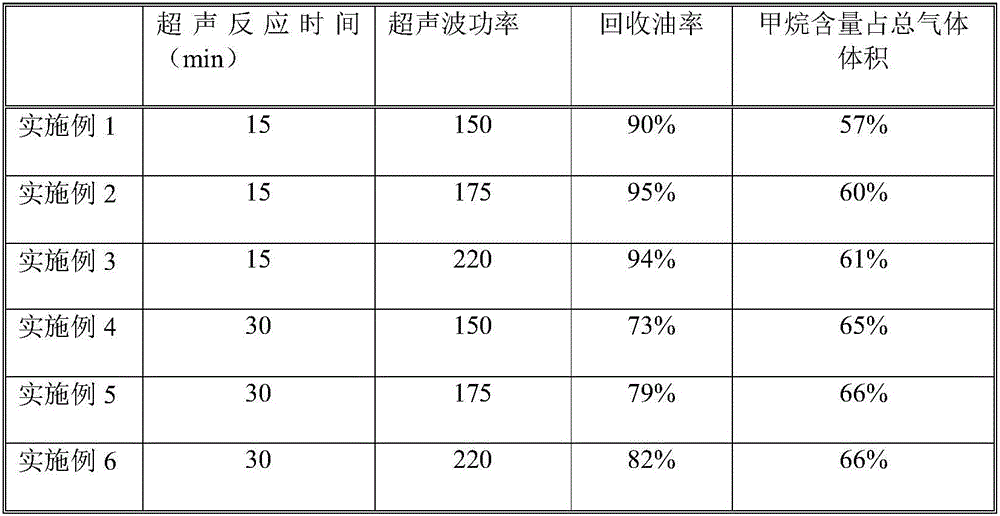

Embodiment 1

[0031] The oily sludge used in this example has an oil content of 15%, a moisture content of 73%, and a sand content of 10%. The method for the treatment and comprehensive utilization of the oilfield drilling sludge comprises the following steps in sequence:

[0032]1) Removal of solid impurities: mix oily sludge and water at a mass ratio of 1:4, remove solid impurities such as large particles of sediment in the oily sludge through a fine grid after mixing, and the net width of the grid gap is 10mm;

[0033] 2) Removal of heavy metal salts by electroadsorption: passing the oily sludge water treated in step (1) through an electrosorption cell to remove heavy metal salts in the oily sludge;

[0034] The electrode in the electric adsorption cell is prepared by mixing activated carbon powder and carbon black at a mass ratio of 9:2, adding deionized water and absolute ethanol to make a mixed solution, heating at 70°C and stirring for 2 hours, and then pressing into a sheet. into; ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the ultrasonic power used is 175W.

Embodiment 3

[0047] The difference between this embodiment and Embodiment 1 is that the ultrasonic power used is 220W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com