Method for treating chloropyridine wastewater

A chloropyridine and treatment method technology, which is applied in the field of wastewater treatment, can solve the problems of complex treatment methods and low treatment efficiency, and achieve the effects of increasing hydrophobicity, easy precipitation, and improving oxidative decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

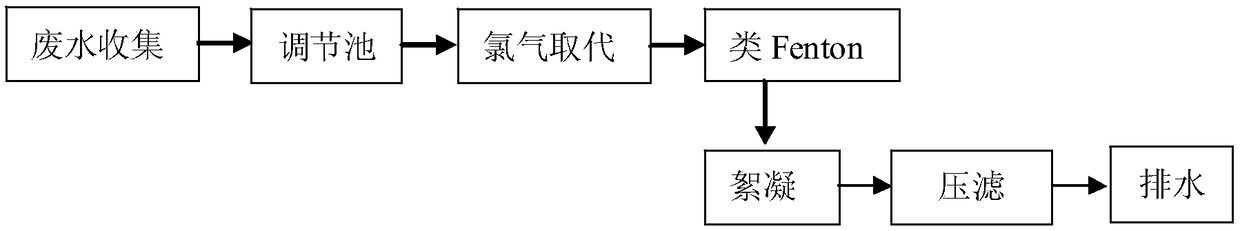

[0034] Processing flow such as figure 1 shown, including the following steps:

[0035] (1) Waste water pH is adjusted to 9, take the quality of waste water as a benchmark, add 0.15% sodium persulfate, under the condition of ultraviolet light, pass into 1.5% chlorine, until the pH of waste water is reduced to 2.3, filter to obtain filtrate 1 ;

[0036](2) Take the quality of filtrate I as a benchmark, add 0.2% ferric chloride in filtrate I, pour it into the high-pressure reactor after fully dissolving, open the heating system, make the temperature stable at 120 ° C, and the system pressure is less than 1.0 MPa, then pump 5% hydrogen peroxide (specification 27.5wt%) oxidant into the autoclave, and react for 120min;

[0037] (3) Adjust the pH of the reaction effluent to 8.6. Based on the quality of the reaction effluent, add 0.001% polyacrylamide PAM (0.1wt%) to increase the floc, and then realize the separation of mud and water by filtering. The quality of the effluent is as f...

Embodiment 2

[0064] (1) Adjust the pH of the wastewater to 9, take the quality of the wastewater as a benchmark, add 0.15% sodium persulfate, and feed 1% chlorine under the condition of ultraviolet light;

[0065] (2) Taking the quality of filtrate I as a benchmark, add 0.2% ferric chloride in filtrate I, pour it into the high-pressure reactor after fully dissolving, and open the heating system; make the temperature stable at 120 ° C, and now the system pressure is less than 1.0 MPa, then pump 5% hydrogen peroxide (specification 27.5wt%) oxidant into the autoclave, and react for 120min;

[0066] (3) Adjust the pH of the reaction effluent to 8.6. Based on the quality of the reaction effluent, add 0.001% polyacrylamide PAM (0.1wt%) to increase the floc, and then realize the separation of mud and water by filtering. The quality of the effluent is as follows :

[0067] pH is 8.6, COD concentration is 3512mg / L, BOD 5 / COD was 0.41, and pyridine compounds were not detected.

[0068] After the...

Embodiment 3

[0070] (1) The pH of the wastewater is adjusted to 9, based on the quality of the wastewater, 0.15% sodium persulfate is added, and 3% chlorine gas is introduced under the condition of ultraviolet light;

[0071] (2) Taking the quality of filtrate I as a benchmark, add 0.2% ferric chloride in filtrate I, pour it into the high-pressure reactor after fully dissolving, and open the heating system; make the temperature stable at 120 ° C, and now the system pressure is less than 1.0 MPa, then pump 5% hydrogen peroxide (specification 27.5wt%) oxidant into the autoclave, and react for 120min;

[0072] (3) Adjust the pH of the reaction effluent to 8.6. Based on the quality of the reaction effluent, add 0.001% polyacrylamide PAM (0.1wt%) to increase the floc, and then realize the separation of mud and water by filtering. The quality of the effluent is as follows :

[0073] pH is 8.6, COD concentration is 2153mg / L, BOD 5 / COD was 0.5, and pyridine compounds were not detected.

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com