A kind of production technology of nicotinamide

A production process and nicotinamide technology are applied in the field of production technology of nicotinamide, and can solve the problems of low product quality, low product concentration, complicated refining process, etc. , the effect of high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 Bacterial classification and the mensuration of enzymatic activity

[0050] (1) Strain construction

[0051] The strain used in this example is: E. coli BL21(DE3) / pET-30a(+)-NHaseP, a genetically engineered strain expressing nitrile hydratase derived from Bordetella petrii DSM12804. For the specific method of genetically engineered bacteria construction, please refer to the invention patent application document with the application publication number CN104498466A entitled "Nitrile Hydratase and Its Application". The base sequence of the nitrile hydratase gene in the genetically engineered bacteria is shown in SEQ ID NO.1.

[0052] Genetically engineered bacteria E.coli BL21(DE3) / pET-30a(+)-pENHase-1229 expressing nitrile hydratase derived from Aurantimonas manganoxydans SI859A (Aurantimonas manganoxydans SI859A), the base of nitrile hydratase gene in genetically engineered bacteria The base sequence is shown in SEQ ID NO.2. The construction method of gen...

Embodiment 2

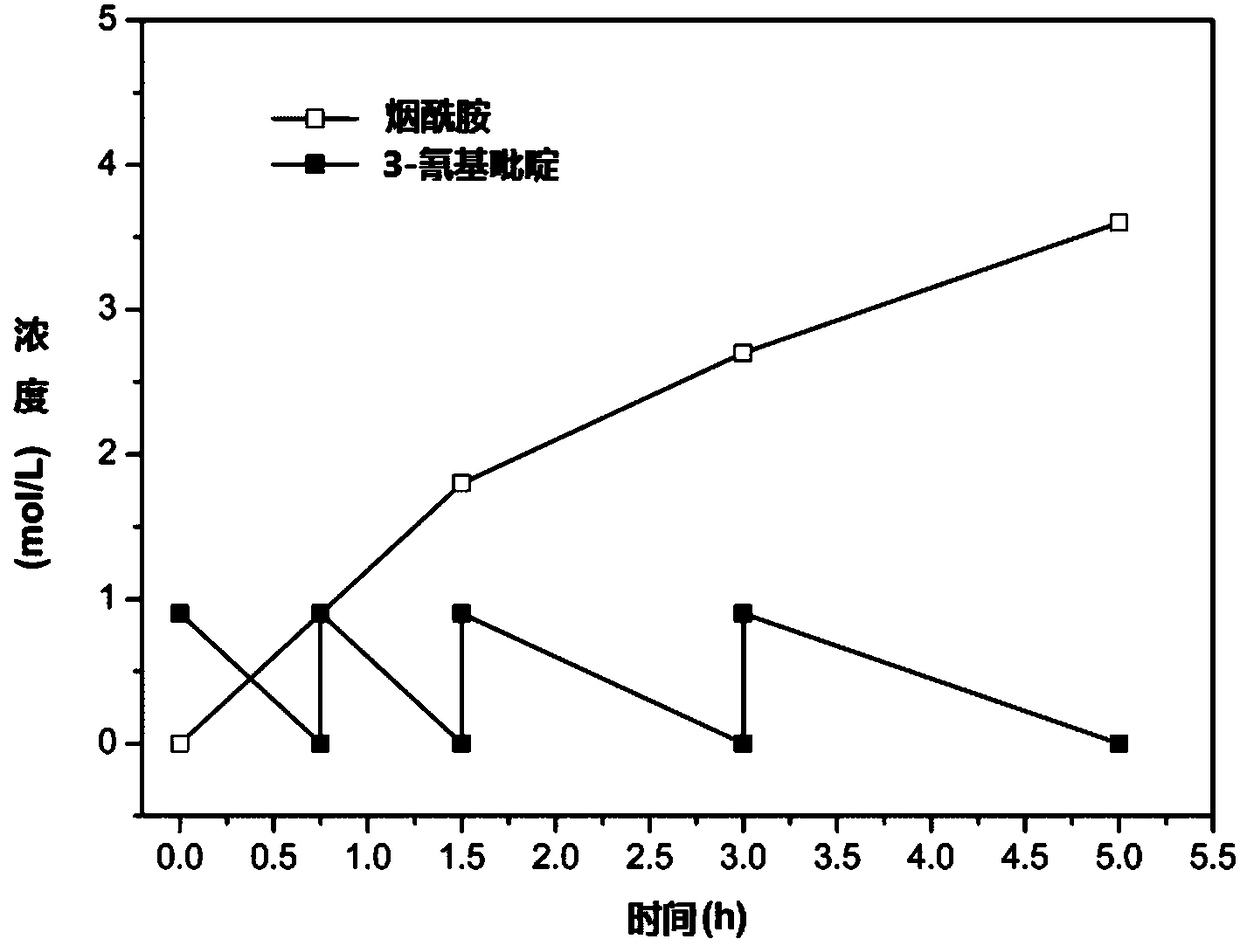

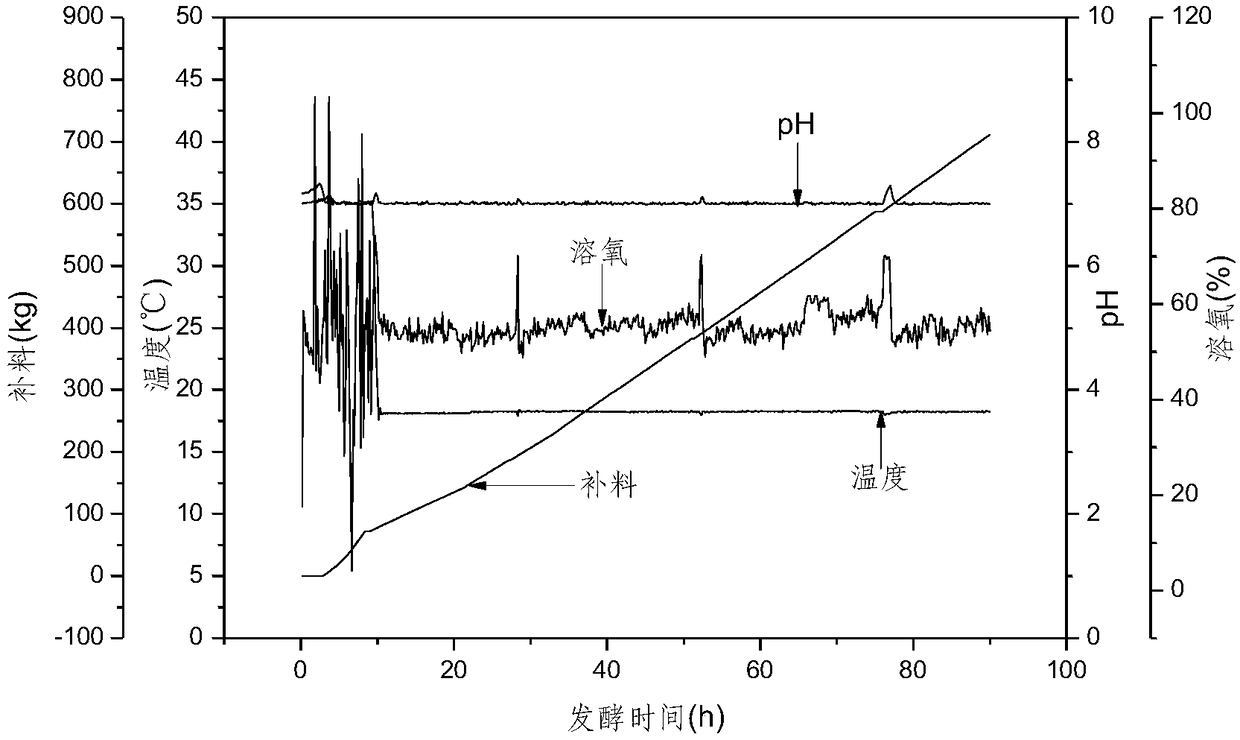

[0073] Example 2 Production of Nicotinamide Using Genetically Engineered Bacteria E.coli BL21(DE3) / pET-30a(+)-NHaseP

[0074] (1) Strain activation: use an inoculation loop to take the genetically engineered strain E.coliBL21(DE3) / pET expressing nitrile hydratase derived from Bordetella petrii DSM12804 (Bordetella petrii DSM 12804) preserved in a -80°C glycerol tube in the strain tube -30a(+)-NHaseP strains were drawn on the surface of LB-Kan-agar solid medium (plate or eggplant bottle), and the plate was placed upside down in a constant temperature incubator at 37°C for 12 hours;

[0075] (2) Seed cultivation: re-inoculate the activated strains into 40mL of primary seed culture medium, culture with shaking at 37°C for 12 hours to obtain primary seed liquid; then, transfer the primary seed liquid into 400mL of secondary seed culture medium with shaking at 35°C for 4 hours to obtain a secondary seed liquid;

[0076] Among them, the primary seed medium is LB medium, 10g / L pepto...

Embodiment 3

[0090] Example 3 Production of Nicotinamide by Genetically Engineered Bacteria E.coli BL21(DE3) / pET-30a(+)-pENHase-1229

[0091] (1) Strain activation: use an inoculation loop to take the genetically engineered strain E.coli BL21 (DE3) expressing nitrile hydratase derived from Aurantimonas manganoxydans SI859A (Aurantimonas manganoxydans SI859A) preserved in a -80°C glycerol tube in the strain tube / pET-30a(+)-pENHase-1229 strains were drawn on the surface of LB-Kan-agar solid medium (plate or eggplant bottle), and the plate was placed upside down in a constant temperature incubator at 37°C for 12 hours;

[0092] (2) Seed cultivation: re-inoculate the activated strains into 50 mL of primary seed culture medium, shake and culture at 37°C for 12 hours to obtain primary seed liquid; then, transfer the primary seed liquid into 500 mL of secondary seed culture medium with shaking at 35°C for 4 hours to obtain a secondary seed solution;

[0093] Among them, the primary seed medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com