Environment-friendly clean production method of high-purity cyanoacetic acid, cyanoacetate and malonate

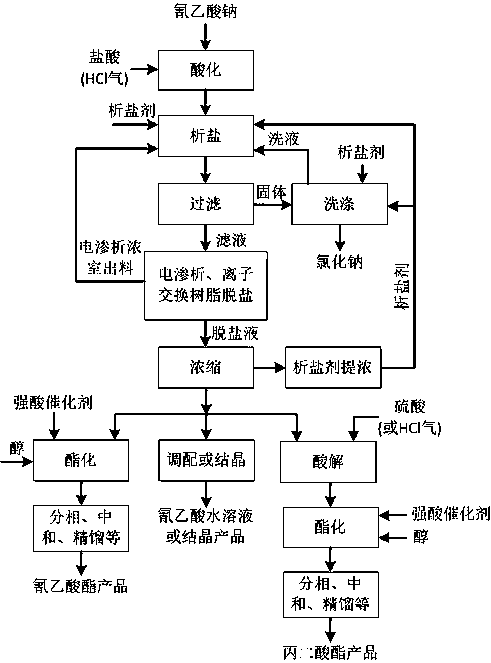

A high-purity cyanoacetic acid and cyanoacetate technology, which is applied in chemical instruments and methods, carboxylate/lactone preparation, carboxylate preparation, etc., can solve the problem of cyanoacetic acid purification or high energy consumption and unclean salt separation , cumbersome operation and other problems, to achieve the effect of solving unclean salt separation, saving investment and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Carry out neutralization reaction through chloroacetic acid and sodium carbonate in water, carry out cyanidation reaction with sodium cyanide solution 1159.4kg (containing sodium cyanoacetate 23.33wt%, sodium chloride 12.88% , water 61.47%), acidified with 296.4L of 31wt% hydrochloric acid to obtain an acidified solution containing cyanoacetic acid and sodium chloride (cyanoacetic acid 14.19wt%, sodium chloride 21.18wt%, water 63.43%), adding a salt-removing agent The mass ratio of the amount of tert-butanol to the amount of water in the acidification solution is 0.25:1, precipitate and filter about 80% of the sodium chloride in the acidification solution at 25°C, and wash the sodium chloride solid with tert-butanol for use. Remove the next salt analysis, and the filtrate after separating sodium chloride is about 1453kg (containing cyanoacetic acid 14.64wt%, sodium chloride 4.31wt%, water 64.89wt%, tert-butanol 16.00wt%), and the filtrate is pretreated by f...

Embodiment 2

[0057] Embodiment 2: same as embodiment 1, utilize above-mentioned electrodialysis desalting process to obtain the desalination liquid that the salt content is lower than 0.05% from the desalination room, carry out negative pressure evaporation and concentration to the water content in the concentrated liquid of about 8wt%, add cyanoacetic acid 1.8 times moles A certain amount of anhydrous methanol, drop an appropriate amount of 98wt% concentrated sulfuric acid catalyst, control the temperature at 60~70°C for esterification reaction, after the reaction is completed, steam the excess methanol under negative pressure, add sodium carbonate solution for washing, neutralization, phase separation, and purification Distillation yields 234.7kg of high-purity methyl cyanoacetate with a content ≥ 99.5%.

Embodiment 3

[0058] Embodiment 3: same as embodiment 1, utilize above-mentioned electrodialysis desalination treatment to obtain from the desalting liquid of desalination chamber that the salt content is lower than 0.05%, carry out negative pressure evaporation concentration to the water content in the concentrate liquid about 12wt%, add cyanoacetic acid 1.85 times moles amount of anhydrous ethanol, add an appropriate amount of 98wt% concentrated sulfuric acid catalyst dropwise, and control the temperature at 60-70°C to carry out esterification reaction. Distillation yields 264.4kg of high-purity ethyl cyanoacetate with a content ≥ 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com