Non-water washing treatment method for formed plate of lead acid battery

A lead-acid battery and a treatment method are applied in the directions of lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction, etc., which can solve the problems of poor treatment effect, low treatment cost, and high treatment cost, so as to alleviate environmental protection pressure, The effect of reducing acid density and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

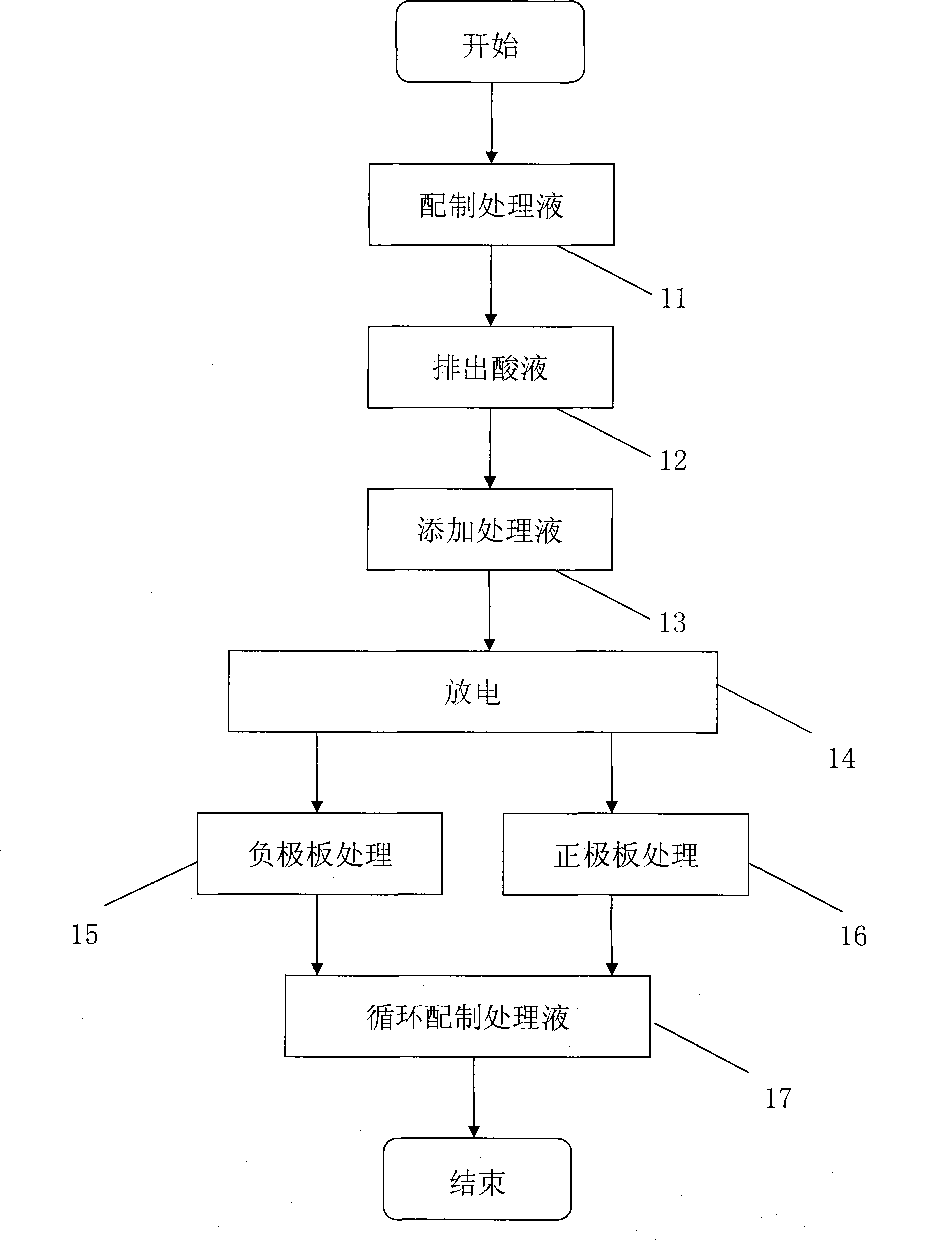

[0076] Such as figure 1 As shown, prepare the treatment solution 11: add quantitative pure water to the treatment solution pool, and add Na at a ratio of 1% to 2%. 2 SO 4 , stir well to get Na 2 SO 4 solution.

[0077] Discharge acid solution 12: After the formation is completed, open the acid discharge valve at the bottom of the formation tank, drain the acid solution in the formation tank to the electrolyte density adjustment pool, and then use a small amount of pure water to wash off the residual acid solution at the bottom of the formation tank .

[0078] Adding treatment solution 13: close the acid discharge valve, open the treatment solution valve, and add 1% to 2% Na prepared into the chemical formation tank 2 SO 4 solution until the positive and negative plates are completely submerged.

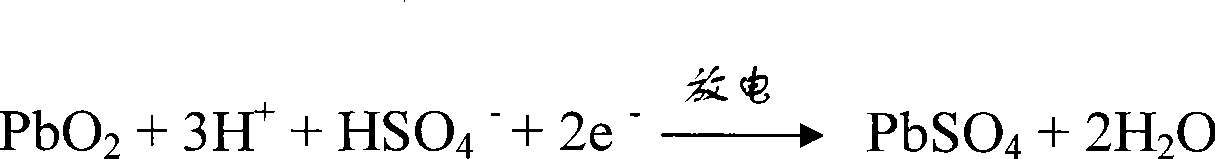

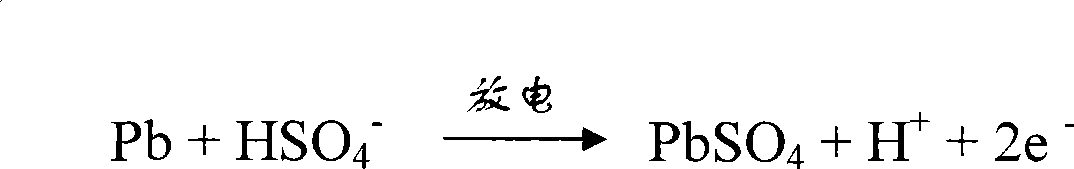

[0079] Discharge 14: Put the charging power supply of the formation in the discharge state, discharge the formation plate, the discharge current is 30% to 50% of the maximum c...

Embodiment 2

[0084] Such as Figure 4 As shown, prepare the treatment solution 11: add quantitative pure water to the treatment solution pool, and add Na at a ratio of 1% to 2%. 2 SO 4 , stir well to get Na 2 SO 4 solution.

[0085] Make the processing tank 21: use a non-welded chemical forming tank of the same size as the chemical forming tank as the processing tank, place a non-welding forming frame in the tank, insert the lead alloy bus bar at the corresponding position of the lower part of the forming frame, and use the lead alloy grid as the positive electrode plate, insert it into the corresponding tooth slot, and weld it firmly to the busbar to form the positive plate group.

[0086] Add treatment solution 13: add 1% to 2% Na prepared into the treatment tank 2 SO 4 solution, the amount added should be able to ensure that the negative plate is completely submerged when the negative plate is inserted in the next step.

[0087] Insert the negative plate 22: take out the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com