Dish-washing machine water saving method and dish-washing machine

A dishwasher and salt water technology, which can be used in the washing machine/rinsing machine parts of tableware, sustainable construction, climate sustainability, etc., can solve the problem of high water consumption and achieve the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

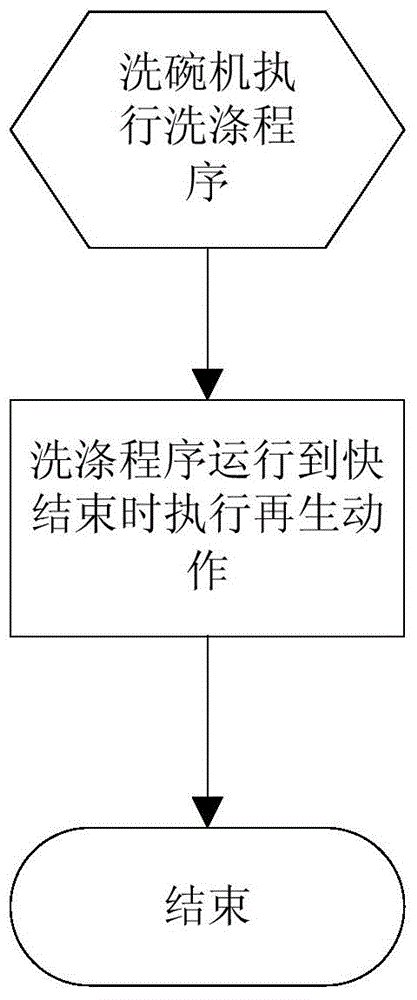

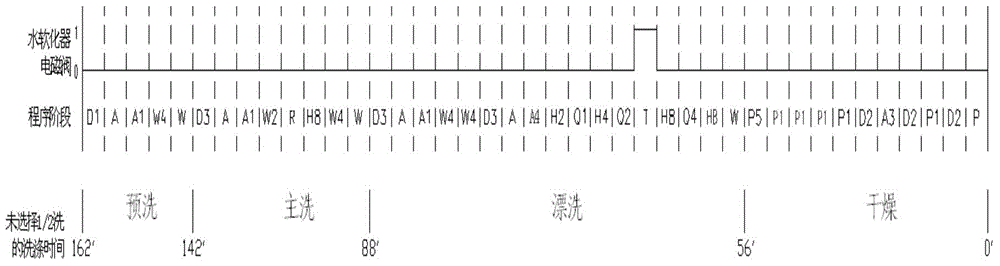

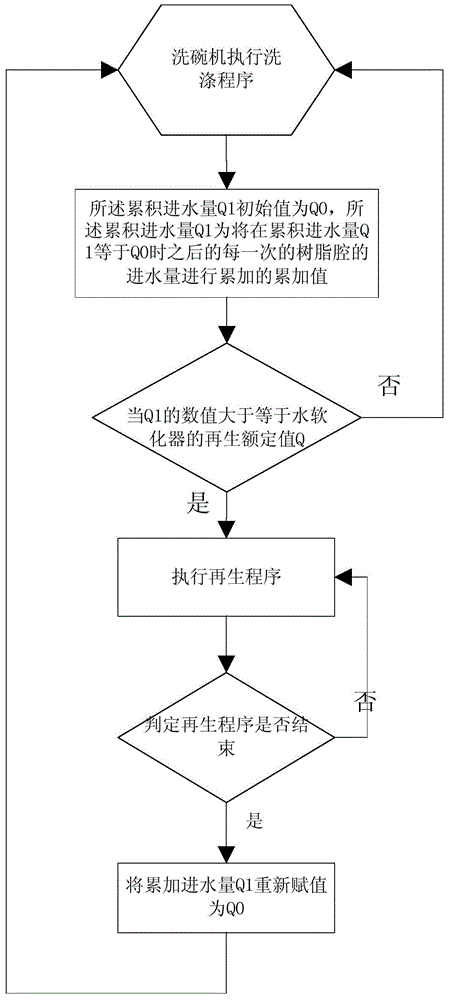

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] Such as image 3 As shown, a water-saving method for a dishwasher includes a water softener, the water softener includes a salt chamber for storing saturated brine and a resin chamber for storing resin, and the salt chamber and the resin chamber There is a pipeline connected to it, and a one-way valve is set on the pipeline. The method is to compare the accumulated water intake Q1 entering the resin chamber with the regeneration rating Q set by the water softener, and judge whether to control the water softening according to the comparison result. The device performs regeneration operation.

[0022] The concentrated saline solution stored in the salt chamber is used to replace the calcium and magnesium ions in the resin chamber, and the salt chamber and the resin chamber are connected and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com