Method and loading plate for degumming cleaning silicon wafer

A technology for degumming silicon wafers and loading plates, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve the problems of poor cleaning effect, inability to separate silicon wafers, and low production efficiency. The effect of improving labor productivity, shortening cleaning time, and lowering manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

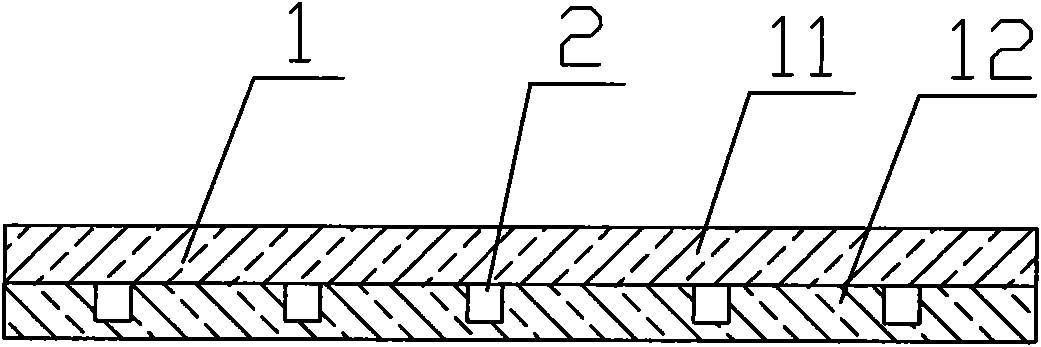

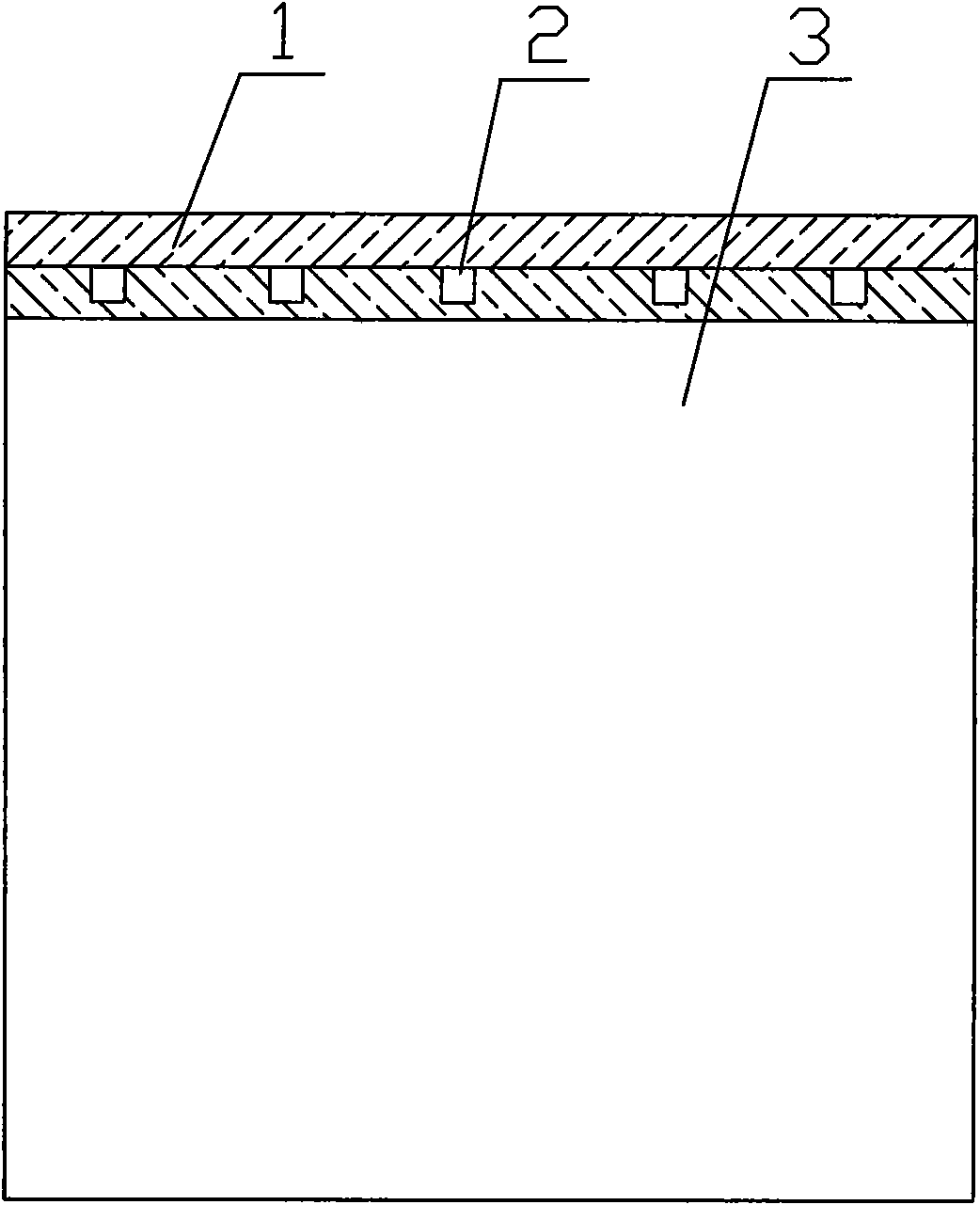

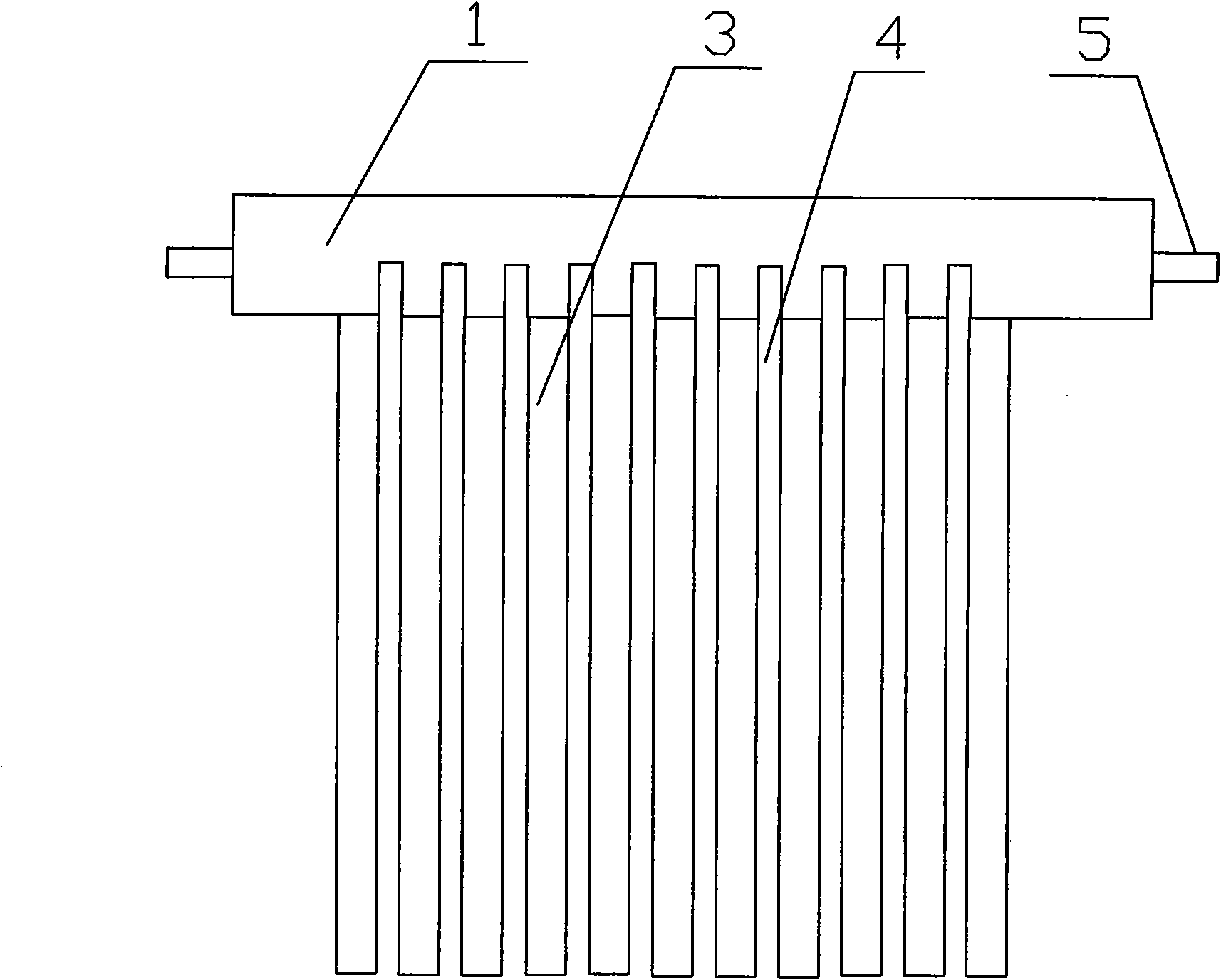

[0025] Loading plates for debonding and cleaning of silicon wafers such as figure 1 As shown, there are holes 2 distributed in the loading plate 1, the holes 2 are connected with the water pipe 5, and the cross-sectional area of the holes 2 is 15-40mm 2 , the spacing between the channels 2 is 20-40mm. Preferable: the cross-sectional area of channel 2 is 20mm 2 , spacing 25mm.

[0026] Further, the loading plate 1 is divided into an upper plate 11 and a lower plate 12, and there is a groove on one of the plates, and the upper plate 11 and the lower plate 12 are connected by bonding, and the grooves on the plate are closed to form a channel after bonding 2. Preferably, the groove is arranged on the lower plate 12 . After being divided into the upper plate 11 and the lower plate 12, the processing of the loading plate 1 is more convenient and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com