Method for linkage production of high-toughness pipeline steel by adopting jetting and laminar cooling

A high-strength toughness, laminar flow cooling technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of low strength of pipeline steel plate and low toughness of pipeline steel plate, achieve stable mechanical properties, good plate shape, and improve customer Effects of Satisfaction and Product Competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

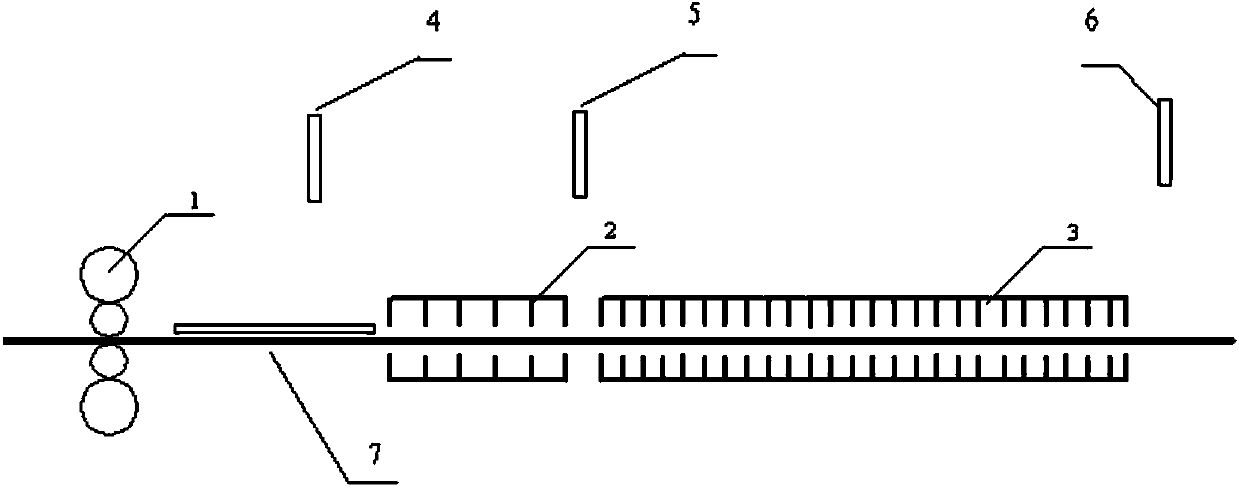

Image

Examples

example 1

[0018] Example 1: 19.1mm X80 pipeline steel

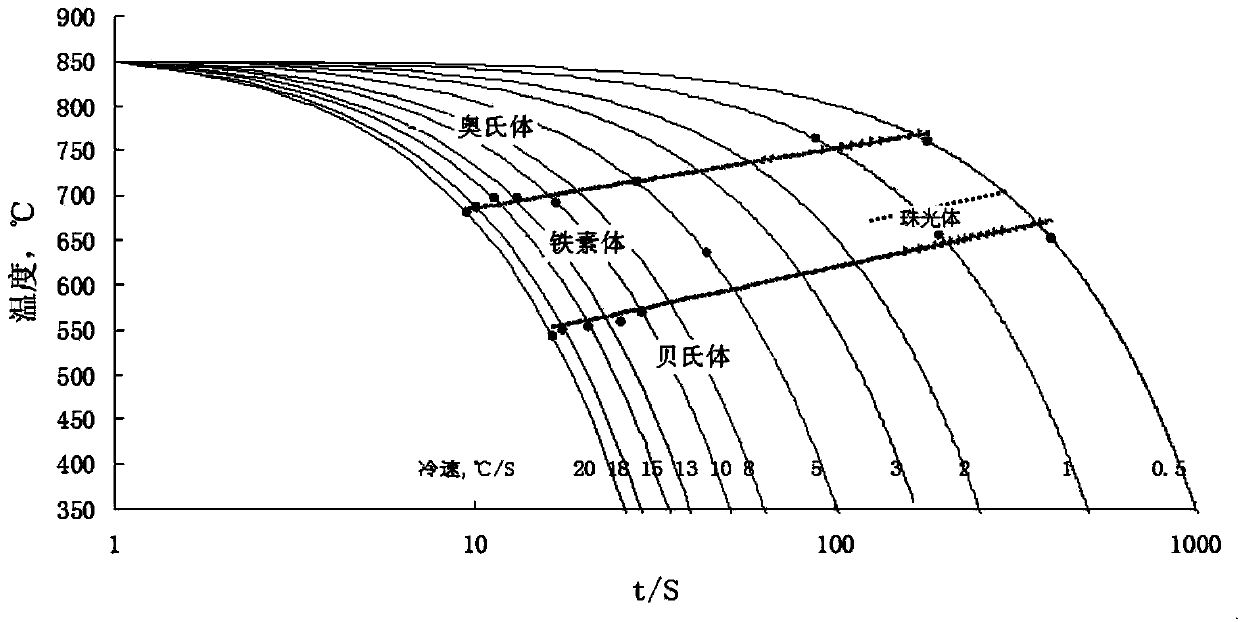

[0019] 1) CCT curve of steel plate (see image 3 )

[0020] image 3 The cooling rates in the medium are 0.05, 0.1, 0.2, 0.5, 1, 2, 5, 10, 20 and 30°C / s respectively

[0021] 2) According to the CCT curve, when the cooling rate is 30°C / s, the bainite transformation start temperature is 550°C, and the UFC cooling final cooling temperature target is determined to be 600°C, the cooling rate is 30°C / s, and the final cooling temperature in the ACC stage is 450-500 , cooling rate 18°C / s.

[0022] The specific process parameters are as follows:

[0023] Steel plate specification

open cold temperature

cooling method

UFC cooling speed

UFC Final Cooldown

ACC cooling rate

ACC Final Cooling

19.1mm

780

UFC-ACC linkage cooling

30℃ / s

600℃

18℃ / s

450-500

[0024] 3) Design steel plate cooling procedures as follows

[0025] The steel plate is cooled by 8 sets of UFC header...

example 2

[0033] Example 2: 25mm X80 pipeline steel

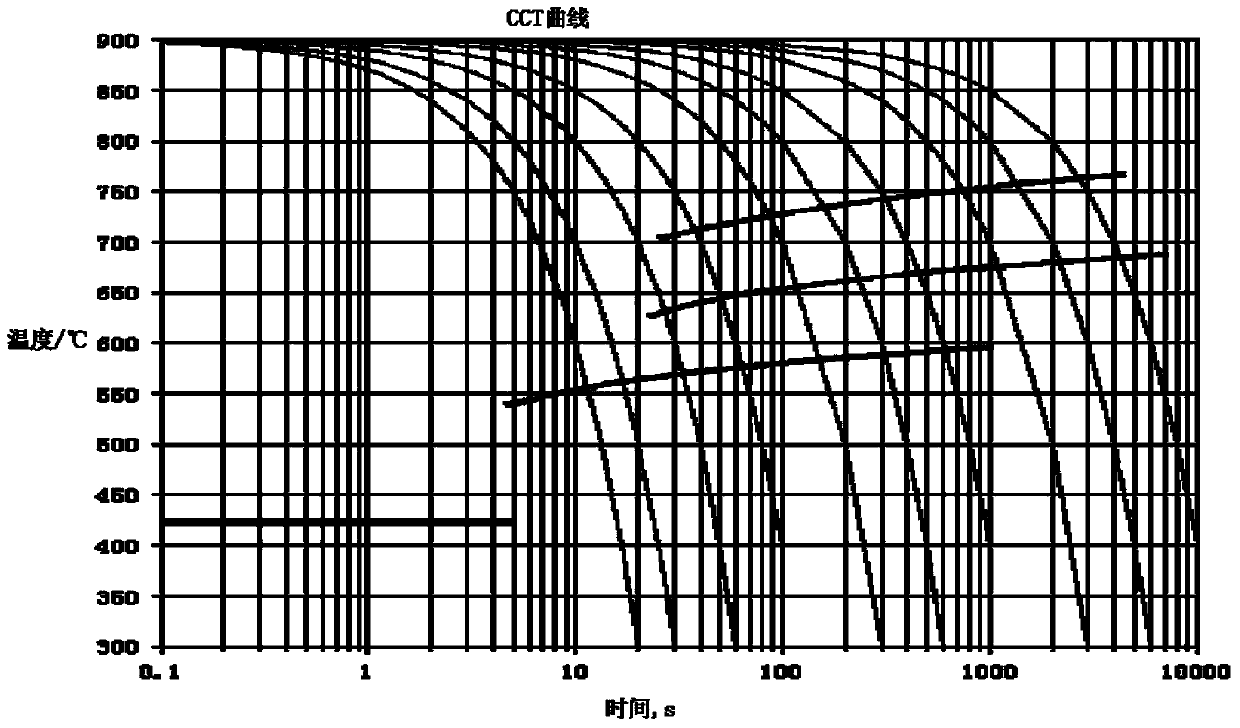

[0034] 1) CCT curve of steel plate (see Figure 4 )

[0035] 2) According to the CCT curve, the final cooling temperature target of UFC cooling is 600°C, the cooling rate is 25°C / s, the final cooling temperature of the ACC stage is 450-500, and the cooling rate is 15°C / s.

[0036] The process parameters are as follows:

[0037] Steel plate specification

open cold temperature

cooling method

UFC cooling speed

UFC final cooling ACC cooling speed

ACC Final Cooling

25mm

780

UFC+ACC linkage cooling

25℃ / s

600℃15℃ / s

450-500

[0038] 3) Design steel plate cooling procedures as follows

[0039] The steel plate is cooled by 9 sets of UFC headers + 4 sets of ACC headers, and the setting parameters of the linkage cooling procedure are as follows:

[0040]

[0041] 4) Mechanical properties of steel plate

[0042] Yield strength requirement: 530~670MPa

[0043] Tensile strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com