Chassis with distributed jet cooling

A distributed and rack-based technology, applied in the field of thermal management systems, can solve problems such as increased heat transfer, new requirements, and limited data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

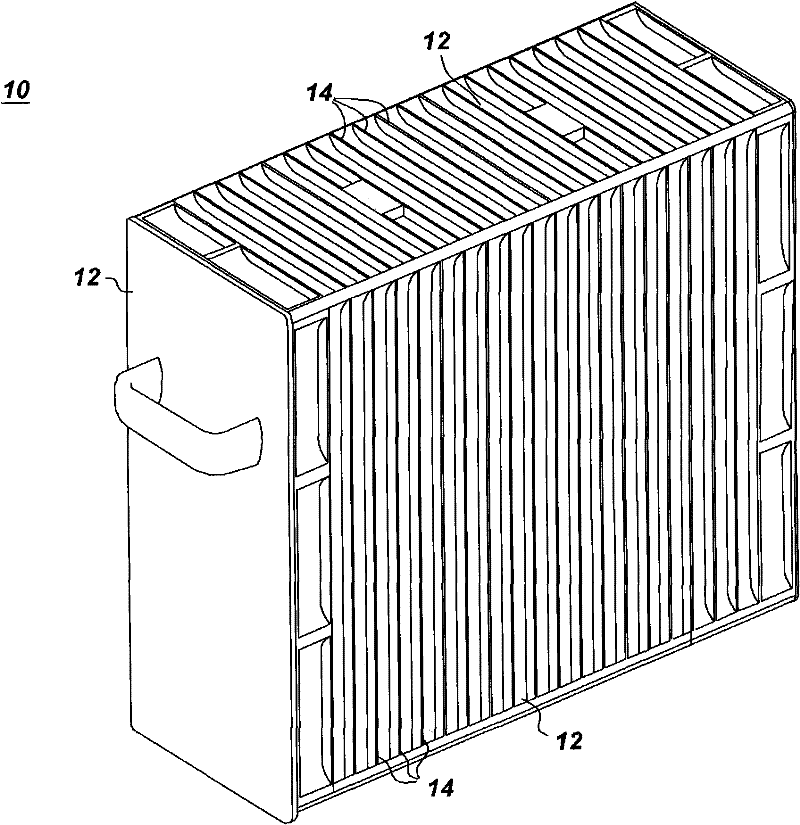

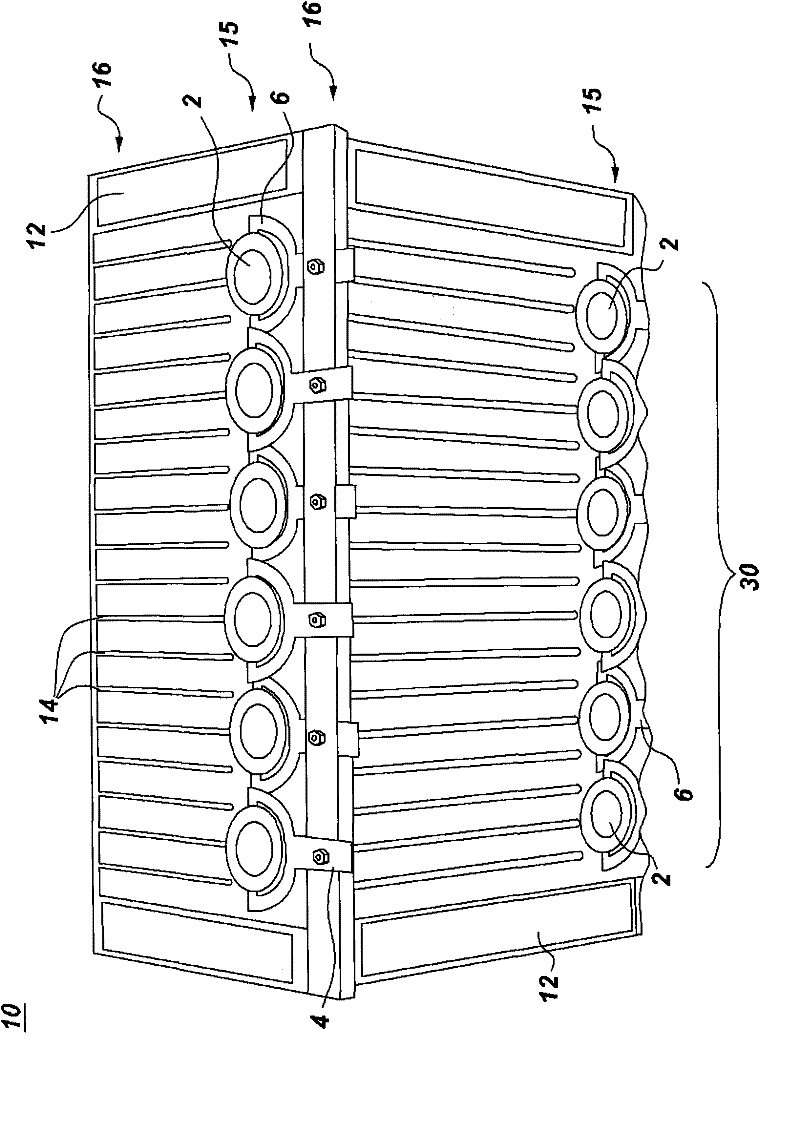

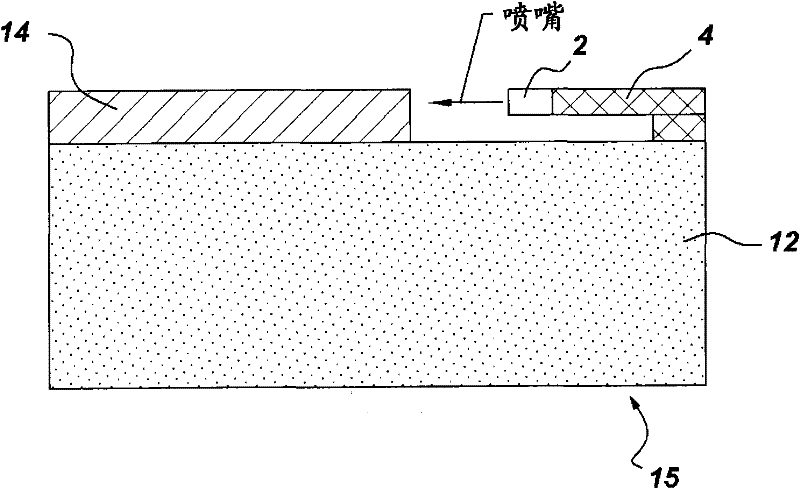

[0065] refer to Figure 1-17 A gantry 10 with distributed nozzle cooling is described. For example figure 1 As shown in , the housing 10 includes one or more side walls 12 defining a volume (not shown) configured to generally surround one or more heat-generating components (not shown) located within the volume. A heat generating component may be any component that requires cooling, non-limiting examples of which include high power processors and power electronics. The frame also includes at least one array of fins 14 thermally coupled to a respective one of the one or more side walls 12 . for figure 1 In the arrangement shown in , the fins 14 are longitudinal plate-like fins. However, other types of fins may also be used, including without limitation pin fins. In short, heat is transferred from the heat-generating component into the side walls, which in turn transfer heat into the fins 14 . Fins 14 increase the surface area for heat transfer to cool heat generating compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com