Pulse jet flow finned cooling device

A pulse jet, cooling device technology, applied in the field of cooling systems, can solve the problems of uneven surface temperature of chips, large pump power, high thermal resistance, etc., and achieve the effects of reducing energy consumption, improving heat dissipation efficiency, and high heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

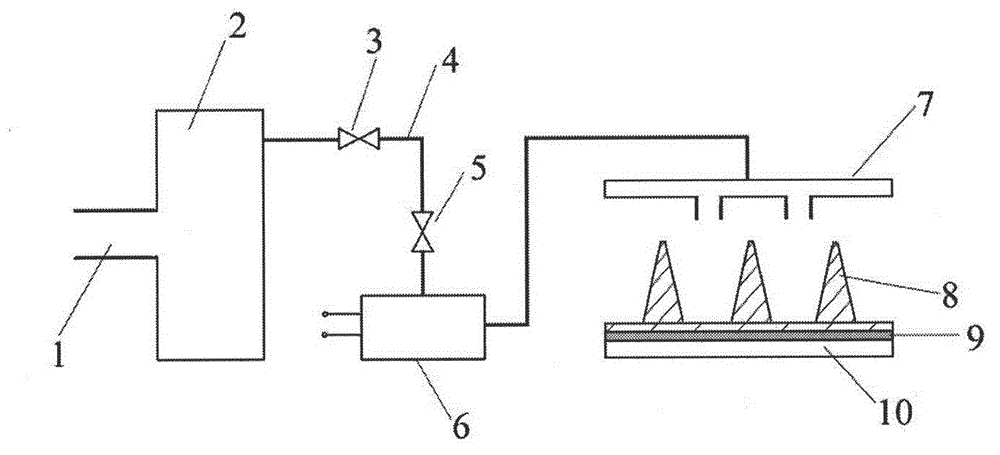

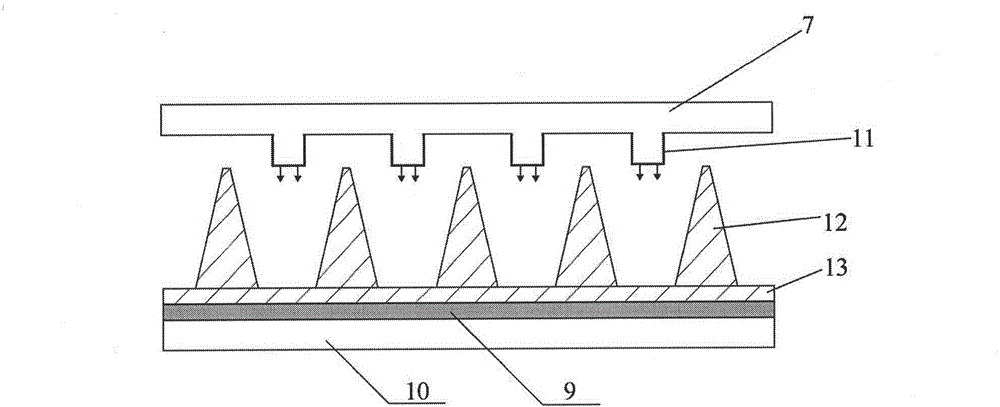

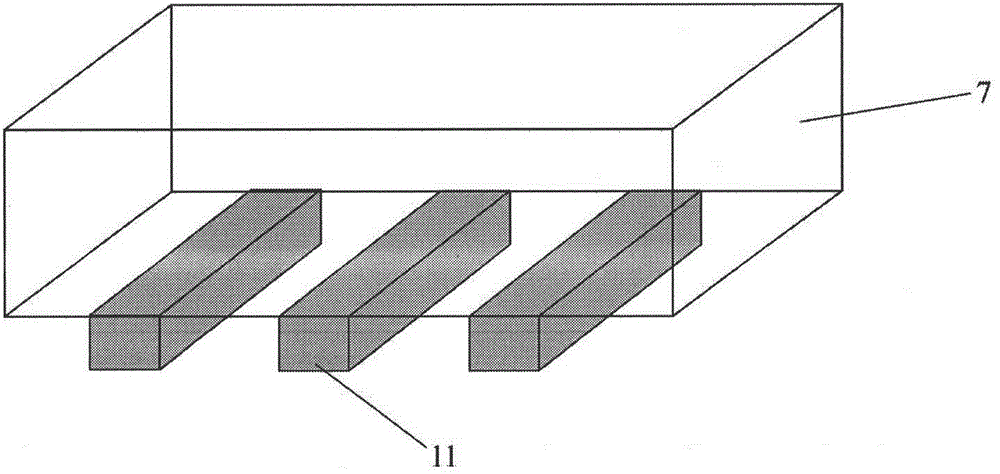

[0014] Such as figure 1 As shown, the present invention includes two parts: a pulsating flow generating device and a jet fin radiator. The gas enters the air compression cylinder 2 from the inlet 1, controls the flow of air in the pipeline 4 through the switch valve 3 and the pressure control valve 5, and enters the electronic signal to drive the steady-state air flow in the acoustic excitation device 6 to convert into a pulsating flow, and the pulsating flow enters The jet array 7 directly hits the surface of the fin 8 through the slit nozzle. The speed of the steady-state airflow entering the electronic signal-driven acoustic excitation device 6 is set by the pressure control valve 5. After the steady-state airflow enters the electronic signal-driven acoustic excitation device 6, it can be converted into an unsteady flow according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com