Continuous annealing equipment

A technology for annealing equipment and manufacturing equipment, applied in the direction of heat treatment equipment, lighting and heating equipment, furnace components, etc., can solve problems such as impact, unevenness, and poor wrinkle patterns, etc., to achieve elimination of operational problems, increase in yield, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

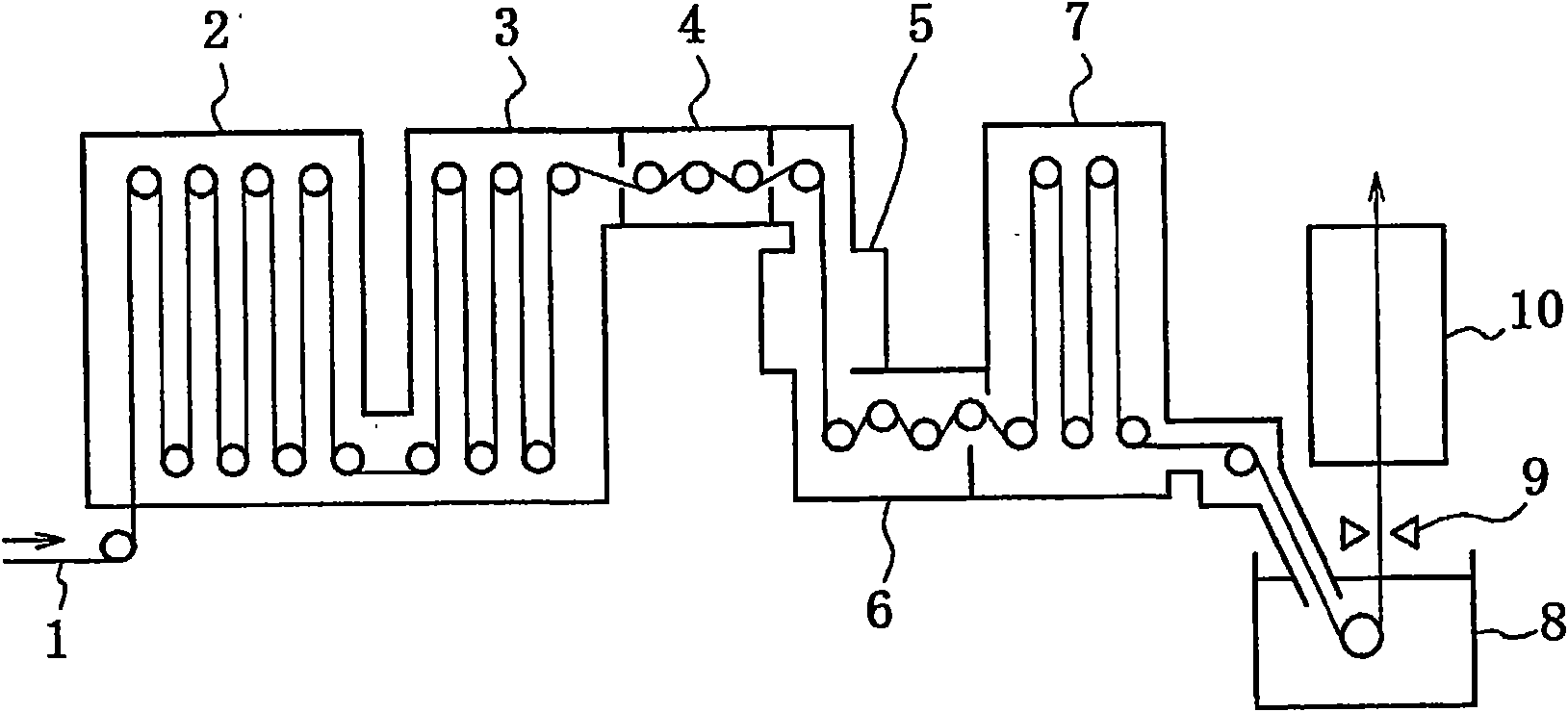

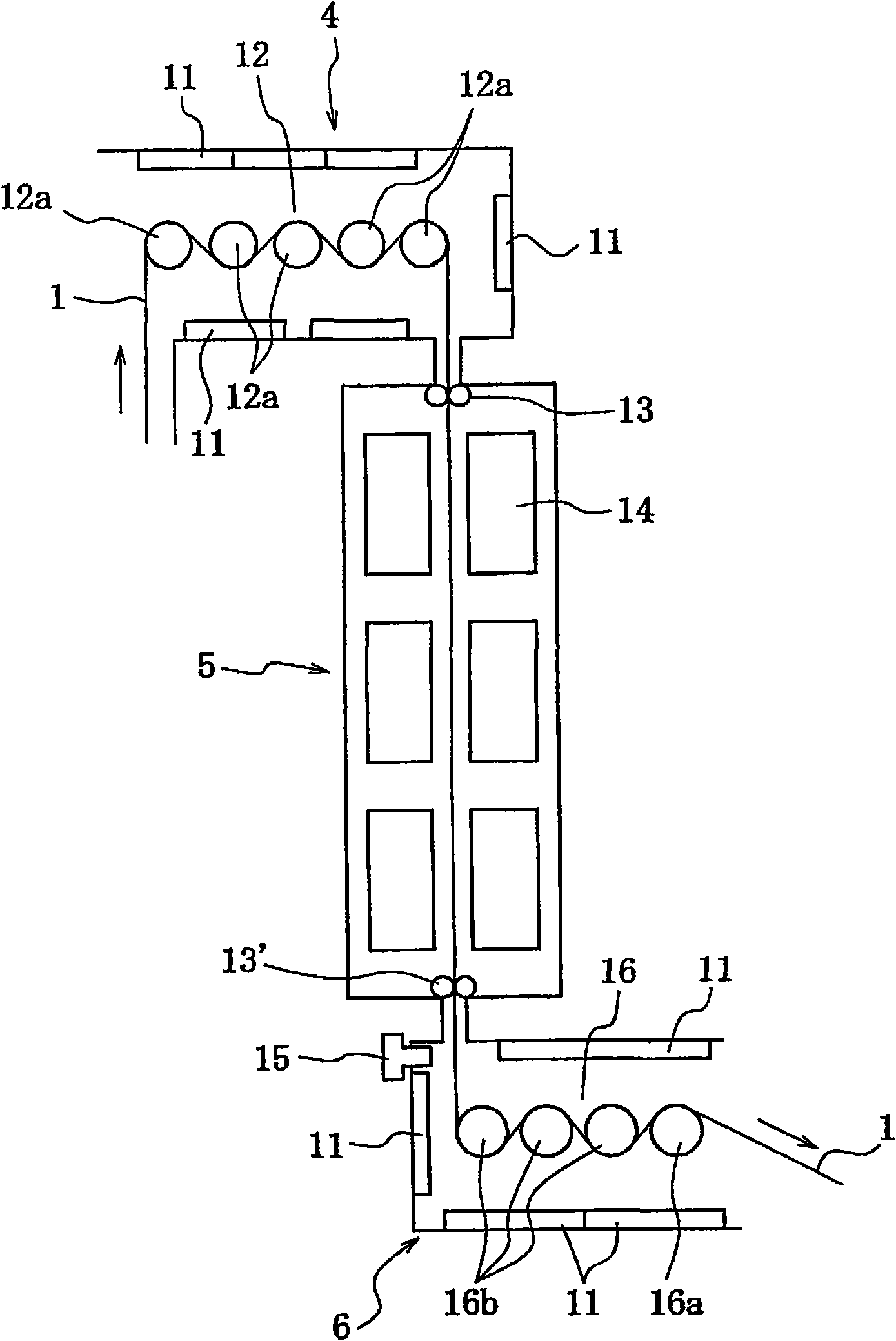

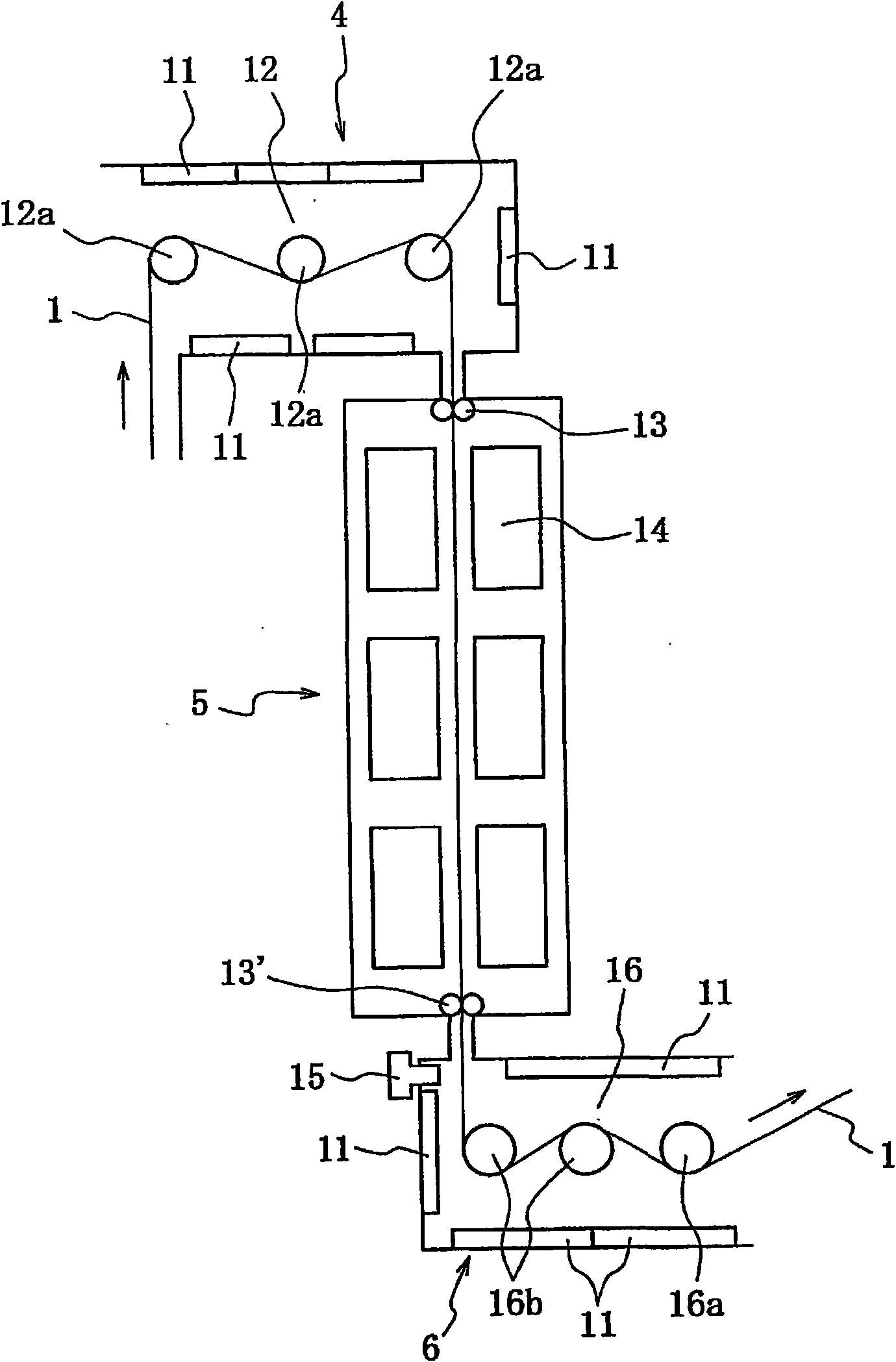

[0056] A cold-rolled steel strip containing C: 0.0005-0.0025% by mass, Nb: 0.005-0.025% by mass, thickness: 0.65mm×width: 1820mm, passed through figure 1 , figure 2 For the alloyed hot-dip galvanizing production line of the continuous annealing equipment shown, the single-sided heat transfer coefficient (α) is 280W / m after annealing at 820-880°C for 2-4 seconds 2 / ℃ gas jet cooling equipment to quickly cool to 500 ~ 550 ℃, then slowly cool and then perform hot-dip galvanizing and alloying treatment to manufacture a unit area weight of 45g / m 2 (Single-sided) alloyed hot-dip galvanized steel sheet. At this time, the passing conditions of the tension roller after the rapid cooling zone (the number of heating rollers used, the winding angle of each heating roller and the total winding angle) are set as follows: the induction heating device is turned on and off to make the heating roller The number of pieces used was changed as shown in Table 1, and the winding angle was change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com