Transformation induced plasticity steel and preparation method thereof

A transformation-induced plasticity, strip technology, applied in metal material coating process, hot dipping process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

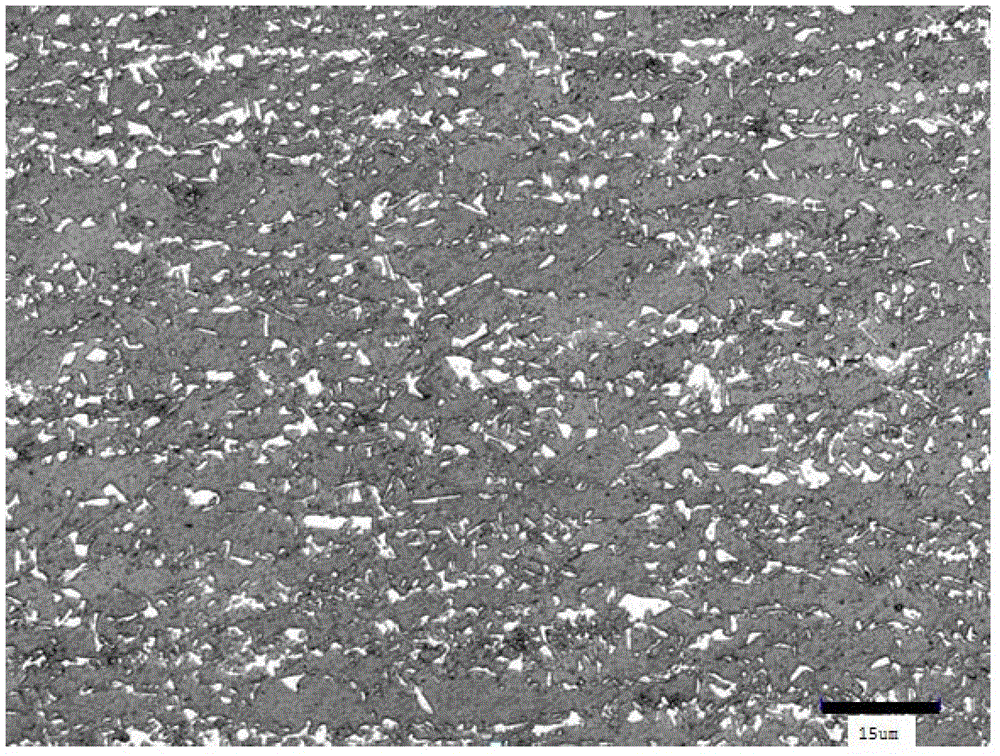

Image

Examples

Embodiment 1

[0028] A kind of phase transformation induced plasticity steel, its chemical composition weight percent is respectively:

[0029] C: 0.19%, Si: 0.5%, Mn: 1.9%, P: 0.008%, S: 0.005%, Alt: 0.9%, N: 0.005%, Nb: 0.03%, and the balance is Fe and impurities.

[0030] The preparation method of phase transformation induced plasticity steel in this embodiment specifically includes the following steps:

[0031] 1) Smelting: Add steel scrap to the converter for smelting. The end temperature of the first furnace during the smelting process is 1670-1690°C; the target temperature of the continuous pouring during the smelting process is 1660-1680°C; during the smelting process, Al-Fe alloy is used to resist Chemical powder deoxidation, the addition of Al-Fe alloy anti-chemical powder is 4kg / t; during the smelting process, slag is added during the tapping process, and the slag is added with the steel flow in the early stage of tapping, and the tapping amount reaches the total steel amount Be...

Embodiment 2

[0046] A kind of phase transformation induced plasticity steel, its chemical composition weight percent is respectively:

[0047] C: 0.21%, Si: 0.6%, Mn: 2.0%, P: 0.01%, S: 0.01%, Alt: 0.8%, N: 0.0008%, Nb: 0.04%, and the balance is Fe and impurities.

[0048] The preparation method of phase transformation induced plasticity steel in this embodiment specifically includes the following steps:

[0049] 1) Smelting: Add steel scrap to the converter for smelting. The end point temperature of the first furnace during the smelting process is 1690°C; the target temperature at the end point of continuous casting during the smelting process is 1660°C; during the smelting process, Al-Fe is used for deoxidation. The addition amount is 4kg / t; during the smelting process, slag is added during the tapping process, and the slag is added along with the steel flow in the early stage of tapping, and all the slag is added before the tapping amount reaches 1 / 5 of the total steel amount, and every...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com