Adsorbent fluidized rotary purifier

An adsorption material and rotary technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of limited purification ability and solid substrate without purification ability, so as to improve desorption efficiency and improve The effect of purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

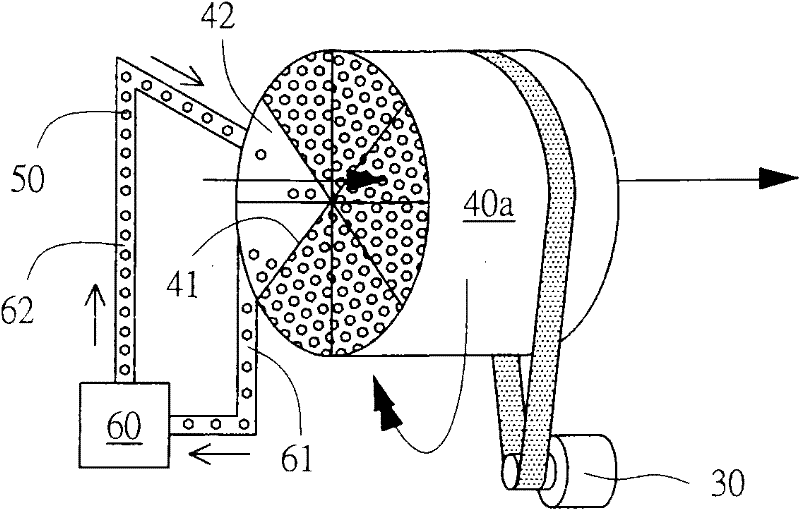

[0041] First, see image 3 As shown, in the first embodiment of the present invention, a runner-type gyrator 40a is radially provided with several partitions 41, and is divided into several accommodating chambers 42 filled with movable adsorbents 50, and a The speed reducer 30 drives the wheel-type gyrator 40a, and an adsorbent filling unit 60 is provided with a discharge pipe 61 and an inlet pipe 62 relative to the wheel-type gyrator 40a, so that the capacity of the wheel-type gyrator 40a The storage chamber 42 sends out the adsorbent 50 through the discharge pipe 61 and feeds the adsorbent 50 in through the feed pipe 62 . However, the adsorbent filling unit 60 is connected with an external desorber to perform the desorption process of the adsorbent, but since it is not the technical content of the present invention, it will not be repeated here. The adsorbent 50 is directly made of porous materials such as activated carbon, zeolite, alumina, or resin, and includes granular,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com