High-chromium nickel-based high-temperature alloy and preparation method and application thereof

A technology of nickel-based superalloy and superalloy, which is applied in the direction of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems affecting the shape and performance of metal components, the increase of grain size, and the deformation of metal components, etc., to achieve Improves strength, uniform grain size, and reduces deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a high-chromium-nickel-based superalloy, which contains Cr 32.6%, Ti 1.14%, Al 1.23%, Ta 2.13%, Nb 1.43%, Mo 2.79%, W 4.57%, Fe 0.32% , C0.014%, B 0.009%, Y 0.008%, and the balance is Ni.

[0038] This embodiment also provides a method for preparing the above-mentioned high-chromium nickel-based superalloy, including the following steps:

[0039] (1) After taking the raw materials of each element and carrying out vacuum smelting, high-chromium-nickel-based superalloy powder (particle size is 45-110 μm) is obtained by gas atomization;

[0040](2) Treat the surface of the base material for additive with an angle grinder first, and then clean it with acetone and alcohol;

[0041] (3) Set the laser scanning path as a "Z"-shaped path;

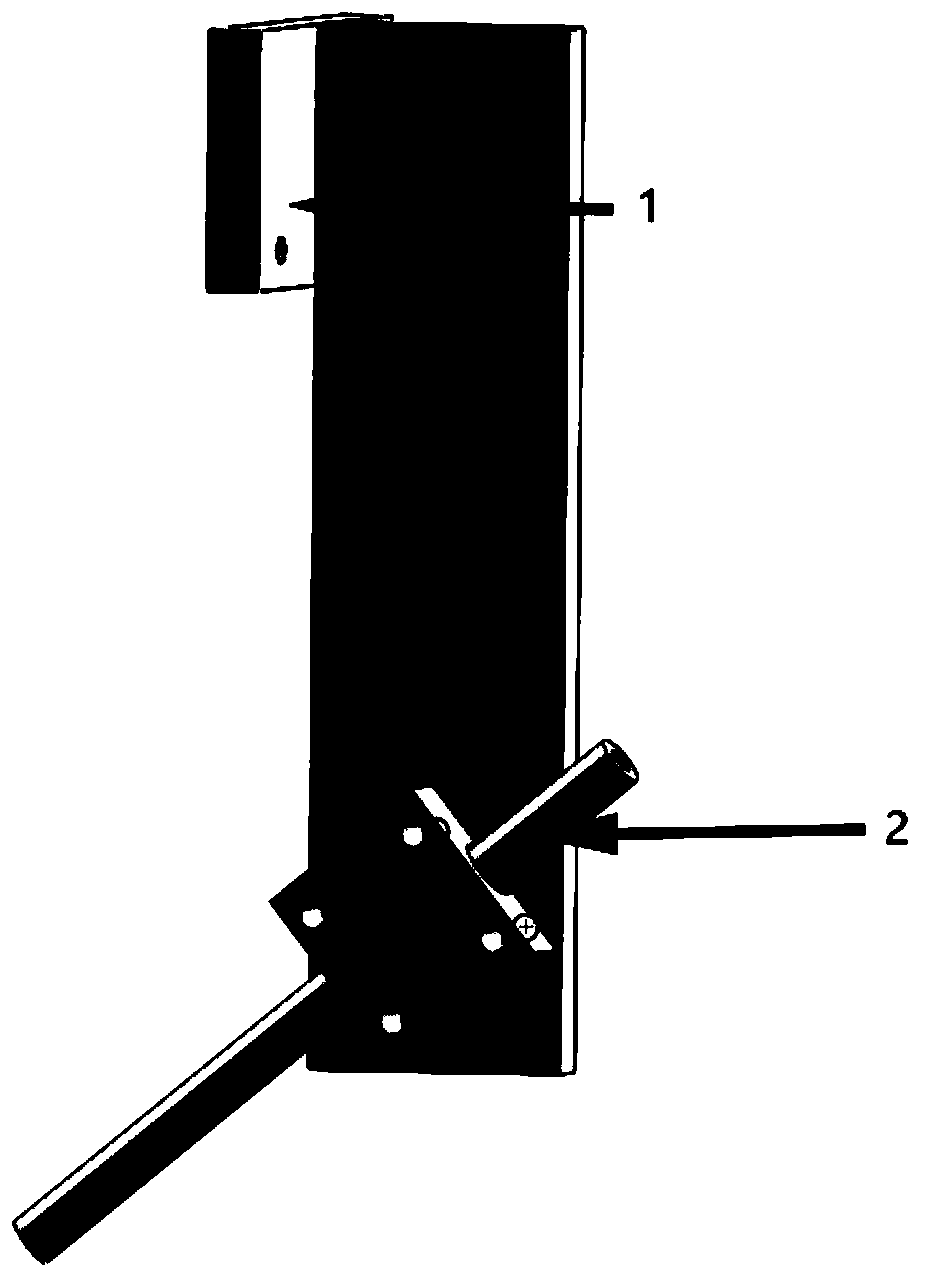

[0042] (4) A cooling device is installed in front of the laser additive manufacturing device (such as figure 1 shown), laser additive manufacturing and cooling are carried out simultaneously;

[0043] Among them, ...

Embodiment 2

[0047] This embodiment provides a high-chromium-nickel-based superalloy, which contains Cr 34.3%, Ti 1.46%, Al 1.28%, Ta 2.14%, Nb 1.78%, Mo 3.23%, W 4.38%, Fe 0.39% , C0.013%, B 0.008%, Y 0.005%, and the balance is Ni.

[0048] This embodiment also provides a method for preparing the above-mentioned high-chromium nickel-based superalloy, including the following steps:

[0049] (1) After taking the raw materials of each element and carrying out vacuum smelting, high-chromium-nickel-based superalloy powder (particle size is 45-110 μm) is obtained by gas atomization;

[0050] (2) Treat the surface of the base material for additive with an angle grinder first, and then clean it with acetone and alcohol;

[0051] (3) Set the laser scanning path as a "Z"-shaped path;

[0052] (4) A cooling device is installed in front of the laser additive manufacturing device (such as figure 1 shown), laser additive manufacturing and cooling are carried out simultaneously;

[0053] Among them,...

Embodiment 3

[0057] This embodiment provides a high-chromium-nickel-based superalloy, which contains Cr 33.7%, Ti 1.67%, Al 1.56%, Ta 2.1%, Nb 1.89%, Mo 2.59%, W 4.15%, Fe 0.42% , C0.023%, B 0.007%, Y 0.005%, the balance is Ni

[0058] This embodiment also provides a method for preparing the above-mentioned high-chromium nickel-based superalloy, including the following steps:

[0059] (1) After taking the raw materials of each element and carrying out vacuum smelting, high-chromium-nickel-based superalloy powder (particle size is 45-110 μm) is obtained by gas atomization;

[0060] (2) Treat the surface of the base material for additive with an angle grinder first, and then clean it with acetone and alcohol;

[0061] (3) Set the laser scanning path as a "Z"-shaped path;

[0062] (4) A cooling device is installed in front of the laser additive manufacturing device (such as figure 1 shown), laser additive manufacturing and cooling are carried out simultaneously;

[0063] Among them, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com