Device for recycling argon through single-tower low-temperature rectification and method for purifying and recycling argon

A cryogenic rectification and argon technology, which is applied in the field of purification and recovery of argon, single-column cryogenic rectification and recovery of argon, and purification and recovery of gas, can solve the problems of high energy consumption, no advantages, and complex structure of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

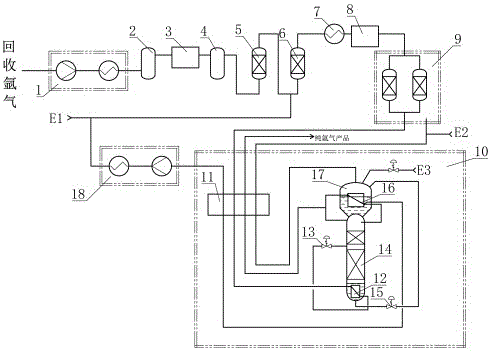

[0077] use as figure 1 The process flow shown purifies the recovered argon:

[0078] Low-pressure recovery argon 2400Nm mixed with about 5% air 3 / h is sent into the recovery argon compressor 1 for pressurization, and the pressure is stabilized by the crude argon buffer tank 2; the pressure of the crude argon output from the crude argon buffer tank 2 is 0.7MPa, and it is pre-cooled by the crude argon gas The machine 3 is pre-cooled and cooled to 6°C, and then enters the oil filter 4 to filter and output crude argon gas with an oil content of less than 1ppm, and then further removes trace oil through the activated carbon adsorber 5 and outputs oil-free crude argon gas; the oil-free crude argon gas Argon is mixed with the imported hydrogen E1 outside the system and recovered hydrogen in the input pipeline of the deaerator 6, and enters the deaerator 6; the deaerator 6 is a catalytic deoxygenation reactor, wherein an active The aluminum oxide palladium-coated catalyst catalyzes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com