Device and method for obtaining high-purity helium gas through concentration and purification

A helium, high-purity technology, applied in the direction of chemical instruments and methods, inorganic chemistry, inert gas compounds, etc., can solve the problems of short life cycle, unsatisfactory, large amount of adsorbent, etc., and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

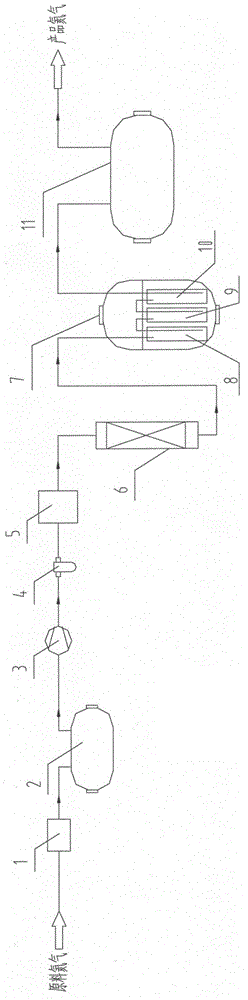

[0036] Such as figure 1 Shown is a schematic diagram of the device structure for enriching and purifying high-purity helium. The device for enriching and purifying high-purity helium comprises a dry dechlorination device 1, a buffer tank 2, a compressor 3, a filter 4, a dryer 5, a drying tower 6, a liquid argon tank 8, a solid Argon tank 9 , adsorption tank 10 and gas storage tank 11 , wherein the liquid argon tank 8 , solid argon tank 9 and adsorption tank 10 are immersed in the liquid nitrogen in the liquid nitrogen Dewar tank 7 . The dry chlorine removal device 1 is an adsorption column with sodium hydroxide as a chemical adsorption filler. The liquid argon tank 8 and the solid argon tank 9 are provided with discharge valves. The liquid argon tank 8, the solid argon tank 9 and the adsorption tank 10 can be recycled. The inlet and outlet of the compressor 3 are equipped with pressure sensors, which are used to stop the compressor when the inlet is low pressure and the out...

Embodiment 2

[0048] Such as figure 1 Shown is a schematic diagram of the device structure for enriching and purifying high-purity helium. The device for enriching and purifying high-purity helium comprises a dry dechlorination device 1, a buffer tank 2, a compressor 3, a filter 4, a dryer 5, a drying tower 6, a liquid argon tank 8, a solid Argon tank 9 , adsorption tank 10 and gas storage tank 11 , wherein the liquid argon tank 8 , solid argon tank 9 and adsorption tank 10 are immersed in the liquid nitrogen in the liquid nitrogen Dewar tank 7 . The dry chlorine removal device 1 is an adsorption column with chemical adsorption filler potassium hydroxide inside. The liquid argon tank 8 and the solid argon tank 9 are provided with discharge valves. The liquid argon tank 8, the solid argon tank 9 and the adsorption tank 10 can be recycled. The inlet and outlet of the compressor 3 are equipped with pressure sensors, which are used to stop the compressor when the inlet is low pressure and th...

Embodiment 3

[0060] Such as figure 1 Shown is a schematic diagram of the device structure for enriching and purifying high-purity helium. The device for enriching and purifying high-purity helium comprises a dry dechlorination device 1, a buffer tank 2, a compressor 3, a filter 4, a dryer 5, a drying tower 6, a liquid argon tank 8, a solid Argon tank 9 , adsorption tank 10 and gas storage tank 11 , wherein the liquid argon tank 8 , solid argon tank 9 and adsorption tank 10 are immersed in the liquid nitrogen in the liquid nitrogen Dewar tank 7 . The dry chlorine removal device 1 is an adsorption column with sodium hydroxide as a chemical adsorption filler. The liquid argon tank 8 and the solid argon tank 9 are provided with discharge valves. The liquid argon tank 8, the solid argon tank 9 and the adsorption tank 10 can be recycled. The inlet and outlet of the compressor 3 are equipped with pressure sensors, which are used to stop the compressor when the inlet is low pressure and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com