Method and device for recycling integrated high-purity nitrogen and argon

A high-purity nitrogen and argon technology, applied in refrigeration and liquefaction, lighting and heating equipment, liquefaction, etc., can solve problems such as inapplicable argon atmospheric pressure out of the tower, reduce operating costs, simplify processes and operations, and improve The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

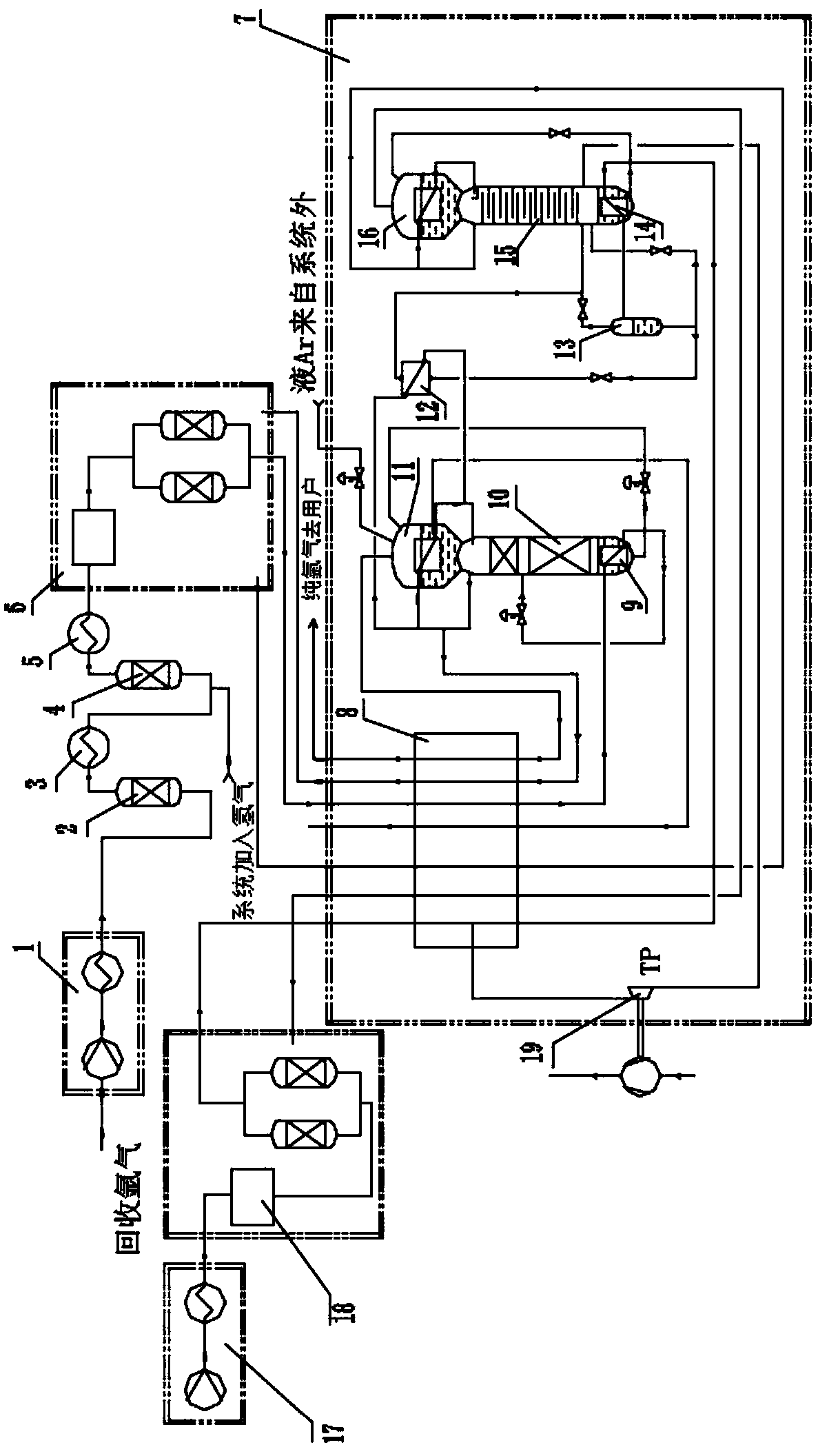

[0041] as attached figure 1 As shown, the pressure of recovering argon (O2<~0.4%, N2<~1.5%, CO:~1500ppm, the rest is Ar) is very low, first pressurized to ~0.5-0.75MPa (A ) and remove oil and dust, it passes through GAr-101 and enters carbon monoxide remover 2. A catalyst is loaded in the carbon monoxide remover 2, and carbon monoxide is catalyzed into carbon dioxide through a catalytic reaction. CO outlet content <1ppm. The argon gas with CO removed comes out through the GAr-102 pipeline and enters the cooler I3 to cool to about 40°C. After being mixed with the added hydrogen in the GAr-103, it enters the deaerator 4. In the deaerator 4, oxygen and hydrogen are generated The reaction produces water and releases heat. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com