Recovery device and recovery method for integrated high-purity nitrogen and argon

A recovery method and high-purity nitrogen technology, which is applied in the field of recovery devices integrating high-purity nitrogen and argon, can solve the problems of many moving parts, low cryogenic rectification, and low extraction rate, so as to improve economic benefits and increase extraction rate , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

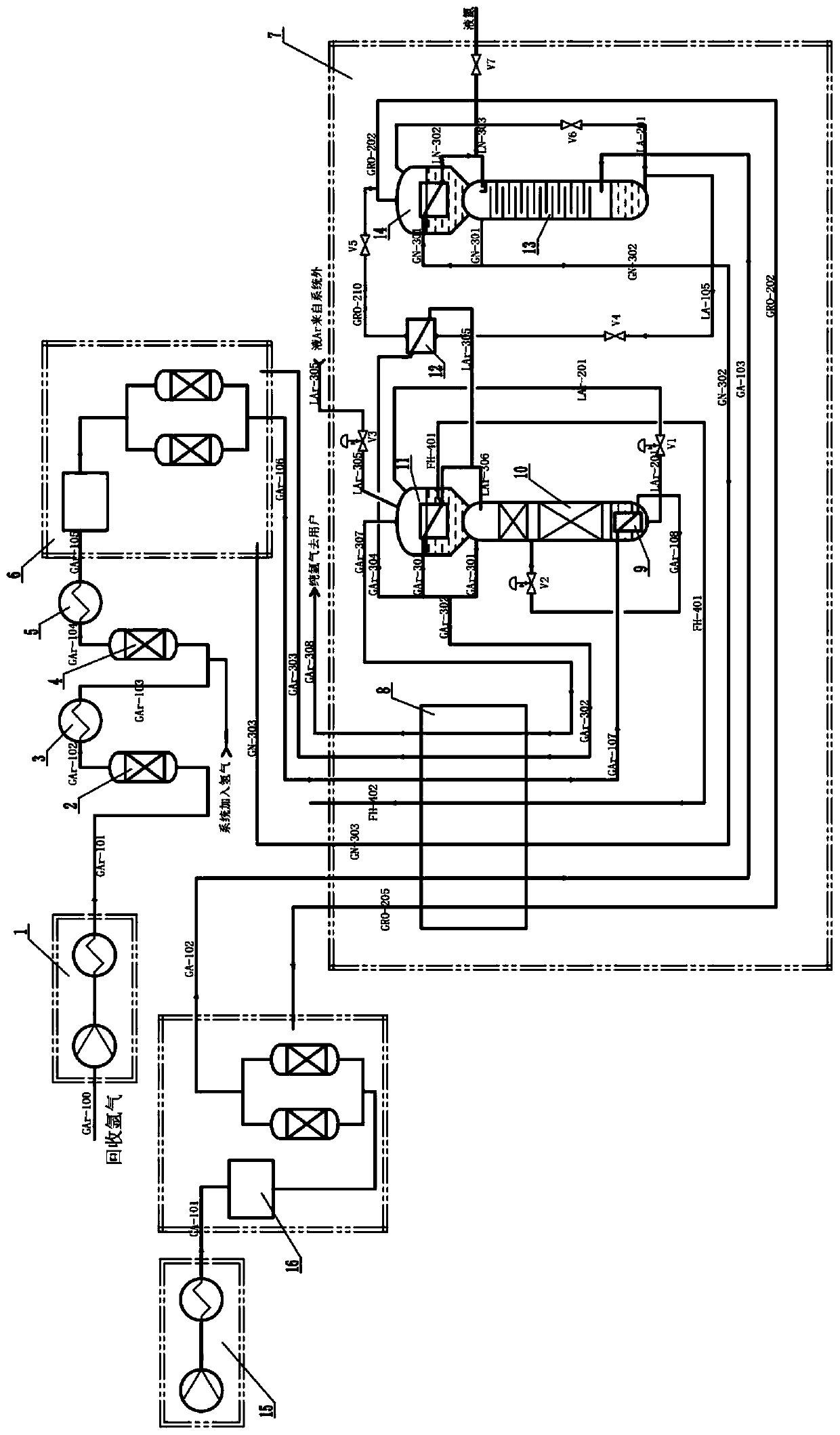

Embodiment 1

[0051] This embodiment aims at the shortcomings of many moving parts, high energy consumption, large investment, and low extraction rate in current argon gas recovery, and provides a low-temperature rectification process with simple and easy operation by utilizing the conditions that monocrystalline silicon manufacturers will have liquid argon supply. For an integrated high-purity nitrogen and argon recovery method that is convenient, lower energy consumption, and higher extraction yields, see figure 1 As shown, including argon recovery flow path and air nitrogen flow path: where:

[0052] The argon recovery flow path includes the following steps S11-S14:

[0053] S11, the pressure of recovering argon is very low, pressurize the recovered argon through the argon compressor 1, remove oil and dust, enter the carbon monoxide remover 2, fill the catalyst in the carbon monoxide remover, and catalyze carbon monoxide through catalytic reaction It is a carbon dioxide tower, which rem...

Embodiment 2

[0068] see figure 1 As shown, this embodiment provides an integrated high-purity nitrogen and argon recovery device for the recovery method described in Example 1 above, including an argon compressor 1, a carbon monoxide remover 2, an oxygen remover 4, an argon gas Precooling and purification system 6, air compressor 15, air precooling and purification system 16, heat exchanger 8, argon tower reboiler 9, refined argon tower 10, argon tower condensing evaporator 11, auxiliary condensing evaporator 12, nitrogen tower 13 and nitrogen tower condensing evaporator 14.

[0069] In this example, if figure 1 As shown, the argon compressor 1 is connected to the argon precooling and purification system 6 through the carbon monoxide remover 2 and the oxygen remover 4 sequentially through pipelines, and the argon compressor 1 is used to add the recovered argon Pressure treatment, the recovered argon gas after pressurization goes through the carbon monoxide remover 2 and deaerator 4 to re...

Embodiment 3

[0081] This embodiment provides an application example based on the recovery method described in the above-mentioned embodiment 1 and the recovery device described in the embodiment 2. For the secondary crystal pulling workshop, the total amount of argon gas recovered generally accounts for 80-80% of the amount used for crystal pulling. 95%, still need to supplement 5% to 20% of liquid argon separately. As far as the specific industry is concerned, 5% to 20% of liquid argon can be added to the recovery process, and its cooling capacity can be used to generate liquid nitrogen to improve the economic benefits of the entire system.

[0082] (1) For the argon recovery flow path:

[0083] Recovery of argon (O 2 2 2 、H 2 Wait.

[0084] Dry crude argon (0.5-0.7MPa(A), 20°C) enters the rectification cold box 7 through the pipeline GAr-106, first enters the heat exchanger 8 to cool down to the liquefaction point, passes through the GAr-107, and enters the refined argon The argon co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com