Device and method for improving argon recycling rate

A technology of recovery rate and argon gas, which is applied in the field of devices to improve the recovery rate of argon gas, can solve the problems of excess hydrogen gas venting, low utilization rate, failure to remove, etc., to simplify the process and operation, improve recovery rate and reduce operation The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

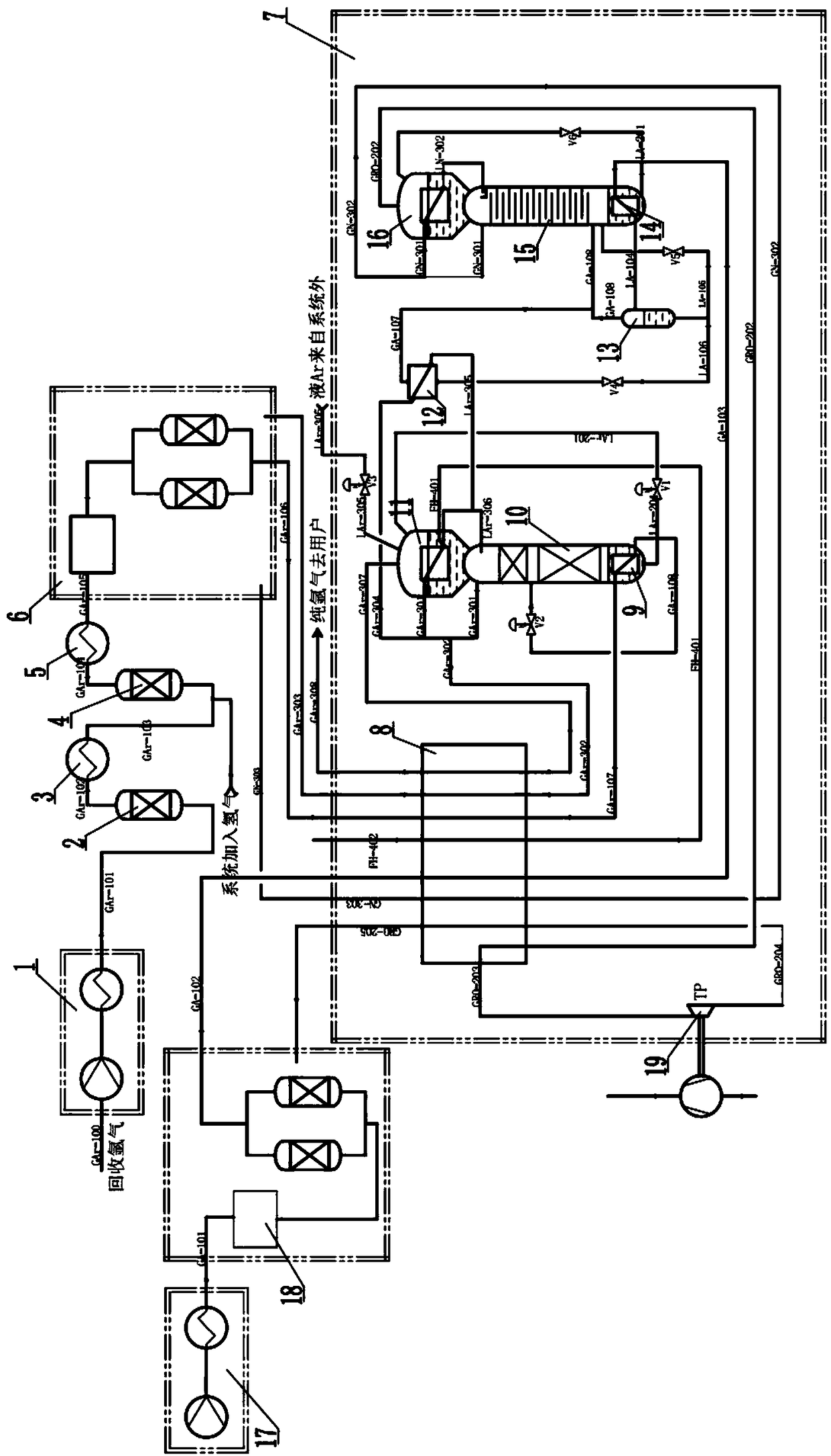

[0037] Such as figure 1 As shown, this embodiment provides a device for improving the recovery rate of argon, which specifically includes: an argon compressor 1, a carbon monoxide remover 2, an oxygen remover 4, an argon precooling and purification system 6, an air compressor 17, Air precooling and purification system 18 and rectification cold box 7, said rectification cold box 7 is built with main heat exchanger 8, argon refining tower 10 and nitrogen tower 15, and the bottom of said argon refining tower 10 is provided with argon tower and then Boiler 9, the top is provided with argon tower condensing evaporator 11, the bottom of described nitrogen tower 15 is provided with nitrogen tower reboiler 14, the top is provided with nitrogen tower condensing evaporator 16, wherein:

[0038] The argon compressor 1, the carbon monoxide remover 2, the deaerator 4 and the argon precooling purification system 6 are connected in sequence for purifying the recovered argon to remove carbon ...

Embodiment 2

[0047] This embodiment provides a method for improving the recovery rate of argon, referring to as figure 1 The flow chart shown specifically includes the following steps:

[0048] (1) After the argon gas to be recovered is purified and treated by the argon compressor 1, the carbon monoxide remover 2, the deaerator 4 and the argon precooling purification system 6, the carbon monoxide, oxygen, water and carbon dioxide in the recovered argon gas are removed , to obtain dry crude argon;

[0049] (2) Send the dry crude argon into the rectifying cold box 7, send it to the argon tower reboiler 9 at the bottom of the argon tower 10 after being cooled by the main heat exchanger 8, and get out the gas-liquid of the argon tower reboiler 9 The mixed fluid is sent to the middle and upper part of the refining argon column 10 through the pipeline through the crude argon throttling valve V2 to participate in rectification. The gas part rises with the gas in the refining argon column 10, and...

Embodiment 3

[0061] This embodiment provides a kind of application of the device that adopts the present invention to improve the recovery rate of argon, please continue to refer to figure 1 The process flow diagram shown has two parts: the main argon recovery flow path and the air nitrogen recovery flow path:

[0062] (1) Argon recovery flow path:

[0063] Argon to be recovered (O 2 2 2 、H 2 Wait.

[0064]The dry crude argon enters the rectification cold box 7 through the pipeline GAr-106, first enters the main heat exchanger 8 to cool down to the liquefaction point, passes through the pipeline GAr-107, and enters the argon column reboiler 9 set up at the bottom of the refined argon column 10 , in the argon column reboiler 9, most of the gas (80% to 95%) is liquefied, and the gas-liquid mixed fluid exiting the argon column reboiler 9 flows out from GAr-108, and is throttled through the crude argon throttle valve V2 The reduced pressure is sent to the middle and upper part of the argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com