Method and device for preparing liquefied methane by using synthesis ammonia tail gas

A technology of liquefied methane and liquefaction equipment, which is applied in the field of recovery and utilization of tail gas from synthetic ammonia, which can solve the problems of greenhouse effect caused by energy carbon dioxide emissions, exhaust waste of synthetic ammonia tail gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

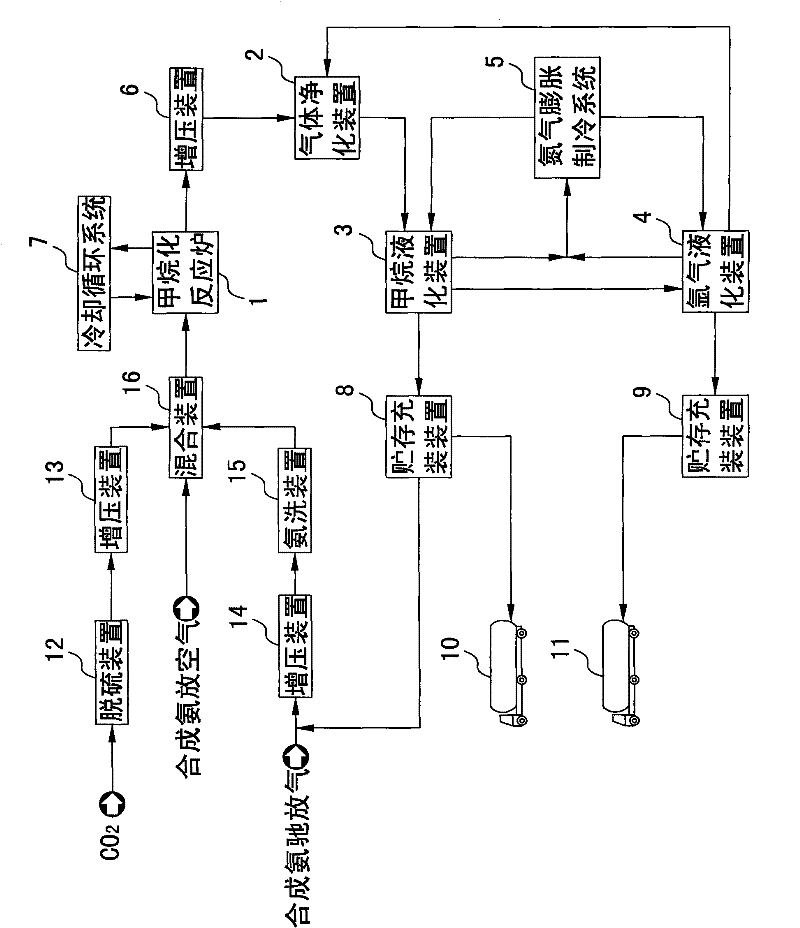

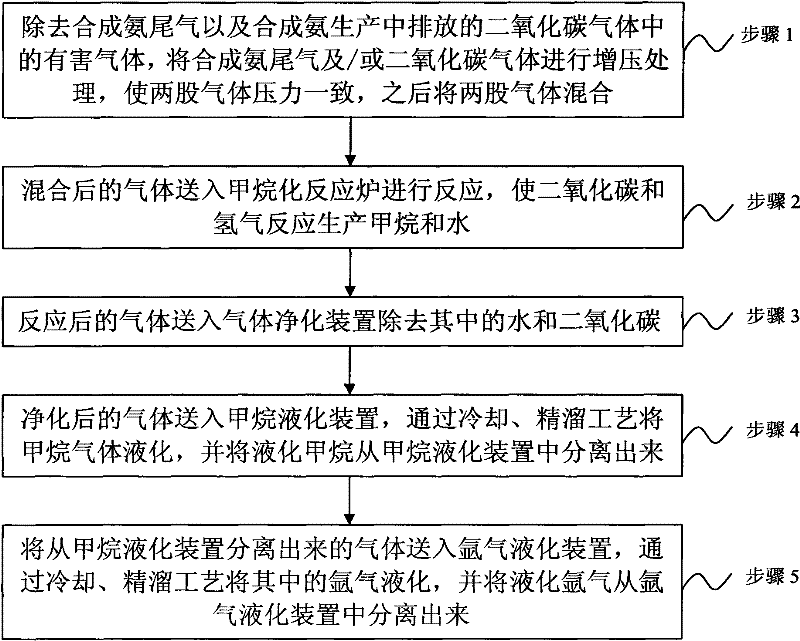

[0052] figure 1 It is a schematic diagram of a system for producing liquefied methane and liquid argon by utilizing synthetic ammonia tail gas of the present invention, as figure 1As shown, the device mainly includes: a methanation reactor 1, which is used to input the tail gas of synthetic ammonia after removal of harmful gases such as ammonia and hydrogen sulfide and pressurized treatment, and the carbon dioxide gas discharged from the production of synthetic ammonia into the methanation reactor 1 Carry out a methanation reaction to react carbon dioxide and hydrogen to produce methane and water; a gas purification device 2, connected to the methanation reactor 1, removes water and carbon dioxide in the gas after the methanation reaction through the gas purification device 2 The methane liquefaction device 3 is connected with the gas purification device 2, and the gas purified by the gas purification device 2 is cooled and liquefied by the methane liquefaction device 3 to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com