Air separation system for recycling cold energy of liquified natural gas

A technology for separation of liquefied natural gas and air, which is applied in the direction of cold treatment separation, liquefaction, refrigeration and liquefaction, etc., can solve the problems of increased energy consumption and large energy consumption, and achieve the effect of compact structure, low cost, and reduced low-temperature pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

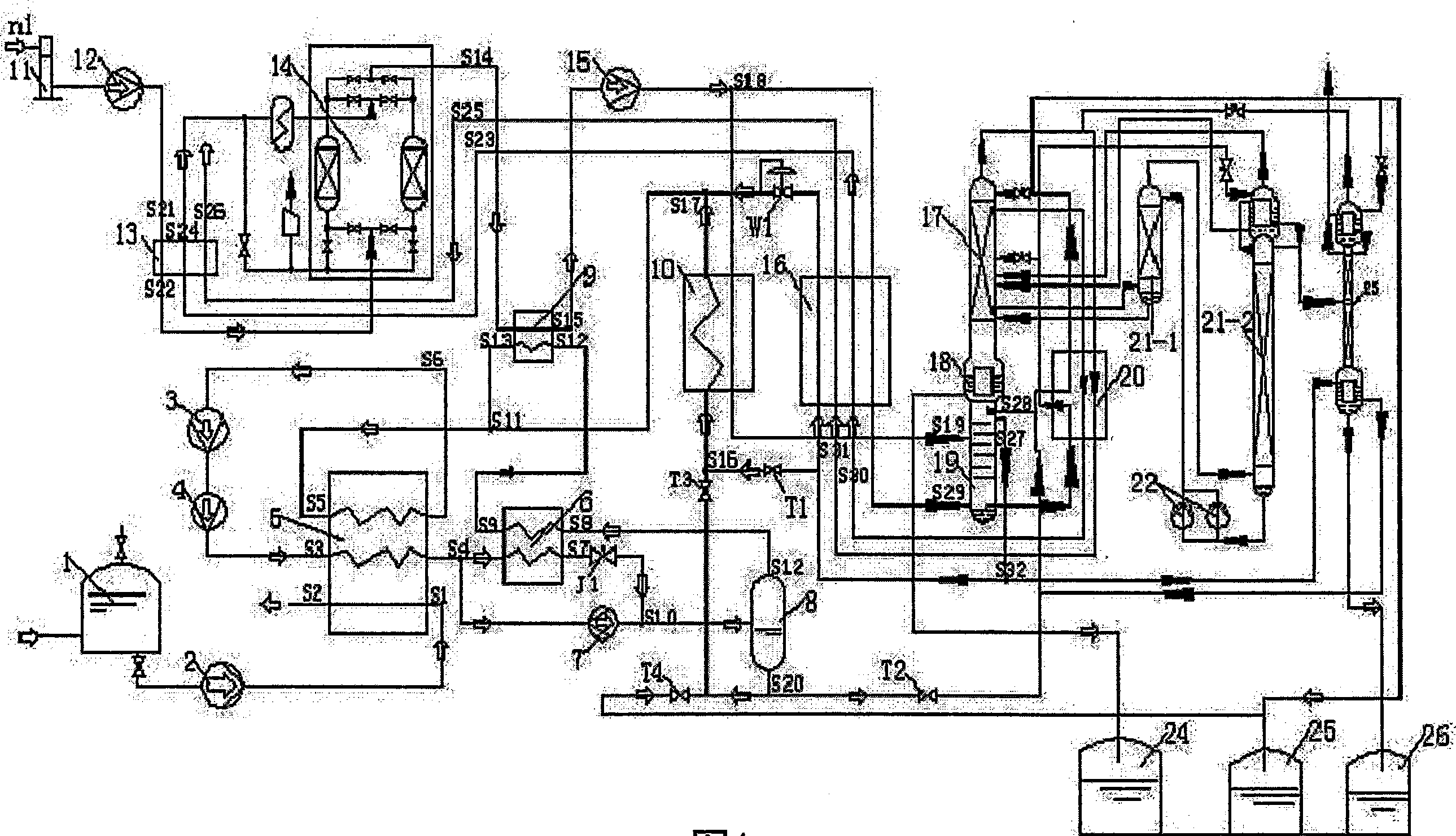

[0017] The first air separation system of the present invention specifically comprises a nitrogen refrigeration cycle device for precooling with liquefied natural gas cold energy, an air liquefaction separation device, an air cooler 9 and an air liquefaction device for connecting the nitrogen refrigeration cycle device and the air liquefaction separation device Device 10, a set of valves and connecting pipelines required for start-up and normal operation, wherein:

[0018] 1.1 The air cooler 9 is provided with a medium-pressure circulating nitrogen heat exchange channel S12→S13 and a raw material air heat exchange channel S14→S15, and the air liquefier 10 is provided with a medium-pressure liquid nitrogen heat exchange channel S16→S17 and Raw material air heat exchange channel S18→S19;

[0019] The nitrogen refrigeration cycle device described in 1.2 includes a liquefied natural gas storage tank 1, a liquefied natural gas booster pump 2, a low-temperature nitrogen cycle booste...

Embodiment approach 2

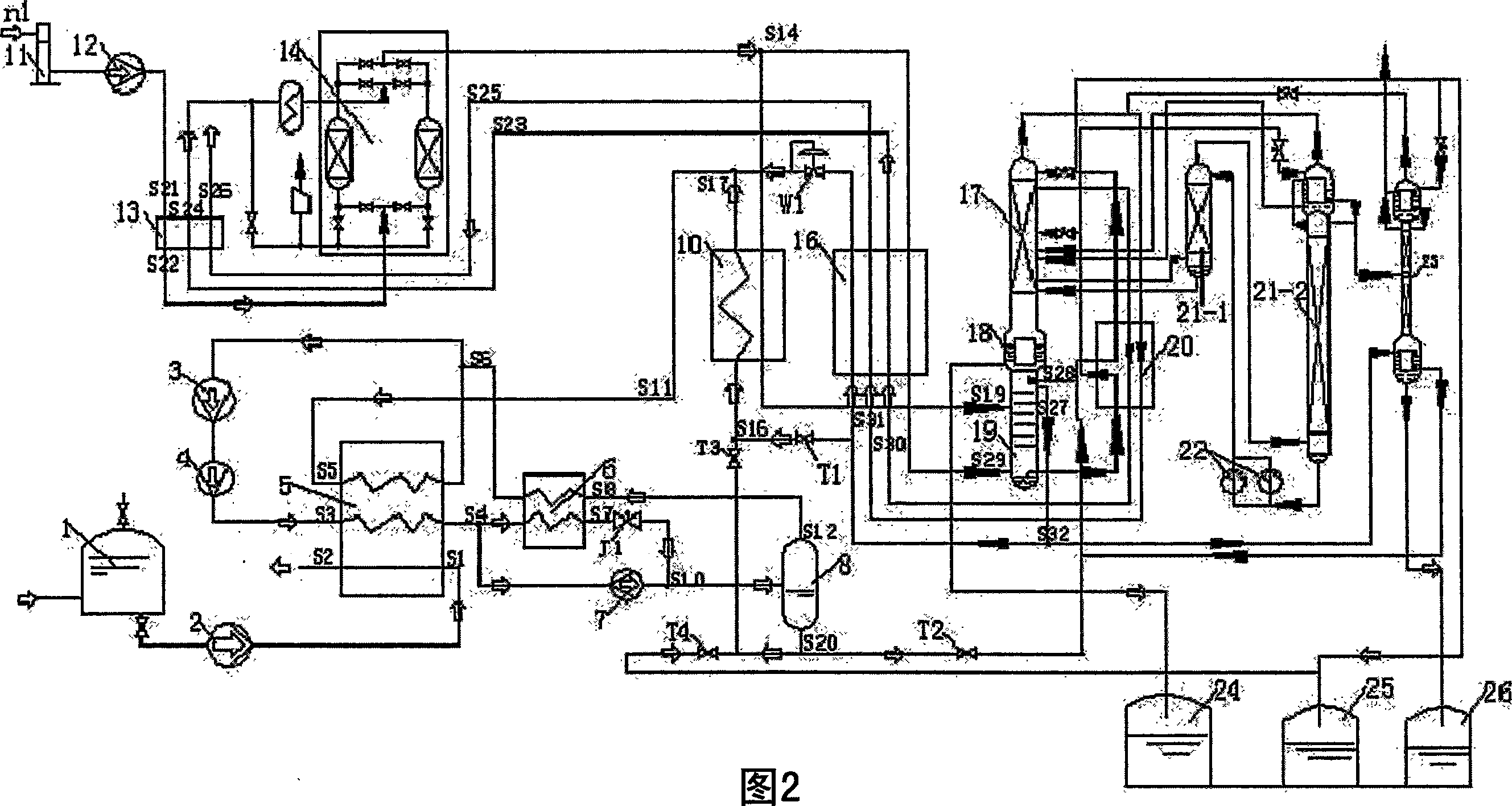

[0034] On the basis of Embodiment 1, other things remain unchanged, the air cooler 9 and the low-temperature air compressor 15 are omitted, the nodes S6 and S9 are combined into node S6; the nodes S14 and S18 are combined into node S14.

[0035] The working principle of this air separation system is:

[0036] (1) The flow process of the nitrogen refrigeration cycle: when the device starts, close the vent valve T2, T4, open the vent valve T1, T3. The nitrogen of 600KPa is drawn from the upper part S27 of the lower tower 19 of the air separation system, and enters the nitrogen through the vent valve T1 The refrigeration cycle system enters the air liquefier 10 (S16→S17) to exchange heat with the raw material air from the molecular sieve 4 (S14→S19), and then enters the liquefied natural gas heat exchanger 5 (S5→S6) to exchange heat with the liquefied natural gas ( S1→S2) to obtain the cooling capacity, the temperature drops to -120℃~-130℃, enters the nitrogen booster 3 to pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com